Alfa Laval Unique Mixproof CP-3 valve (US)

Alfa Laval Unique Mixproof CP-3 valve (US)

The Alfa Laval Unique mixproof CP-3 valve is a highly efficient light-weight, reduced vent mixproof valve – maximizing floor space while greatly minimizing CIP consumption, and virtually eliminating downtime. Ideal for all types of hygienic processes.

It is designed with user flexibility in mind. Configurable for applications in all sanitary industries, including compliance with Grade A Pasteurized Milk Ordinance (PMO) and 3-A Sanitary Standards for continuous dairy processing, the modular design offers a wide variety of options.

Related Industries:

Processed Foods, Dairy, Beverages, Brewery, Home & Personal Care

New Unique PMO mixproof valve based on the original DNA

Proud to be the company behind the dairy industry’s first PMO valve, Alfa Laval introduces its successor: the Alfa Laval Unique mixproof CP-3 valve.

The Alfa Laval Unique mixproof CP-3 valve faithfully lives up to its pedigree, offering dairy processors optimum hygiene and legendary performance. A noteworthy innovation: the Unique mixproof CP-3 valve features a reduced-diameter leak detection vent that make the valve more compact and lightweight.

An efficient, sustainable mixproof valve

The Alfa Laval Unique mixproof CP-3 valve is engineered with the latest efficiency and sustainability principles in mind. A fast and efficient actuator requires a smaller volume of air to execute seat lift and seat push, resulting in low air consumption and minimal CIP fluid loss.

The valve seat is designed with throttling edges on the upper and lower seat plugs, which accelerates cleaning fluid to improve CIP efficiency and uses the absolute minimum amount of CIP fluid.

Reduce cost of ownership and downtime

The Alfa Laval Unique mixproof CP-3 valve provides lower cost of ownership and downtime. Only two seals are located in the valve chamber, which enables faster cleaning of the valve during seat lift and requires less seal spares. When the valve is open during actuation, the lower seat seal is not exposed to wear, resulting in longer seal life. Each valve has a modular design and shares common components with standard Alfa Laval Unique PMO valves of similar size.

One mixproof valve brings safety to all hygienic process types

Not just a dairy valve, the Alfa Laval Unique mixproof CP-3 valve is a reduced-vent mixproof valve. Designed to be configurable, it protects your product no matter the hygienic process type.

The Unique mixproof CP-3 valve not only complies with 3-A Sanitary Standard 85-02 for seat-lift cleaning, but also complies with the FDA Pasteurized Milk Ordinance (PMO), while covering all mixproof dairy, food and beverage applications that require 1½” through 6” port sizes.

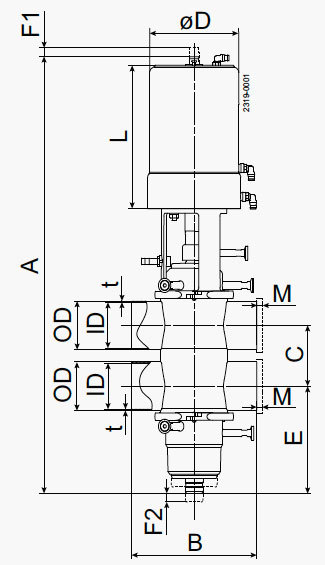

Construction

The Alfa Laval Unique mixproof CP-3 valve is specifically designed for user flexibility and is configurable for all hygienic dairy, food, and beverage applications.

The Unique mixproof CP-3 valve not only complies with 3-A Sanitary Standard 85-02 for seat-lift cleaning, but also complies with the FDA Pasteurized Milk Ordinance (PMO), while covering all mixproof dairy, food and beverage applications that require 1½” through 6” port sizes.

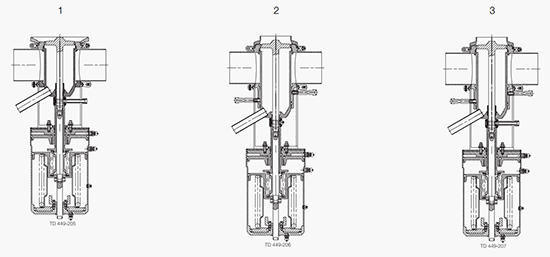

It consists of a valve body, two independent balanced valve plugs/seals that form a leakage chamber between them, actuator with seat lift, position-detectable upper and lower valve seats and a yoke-mounted external sensor.

Operating principle

The Alfa Laval Unique mixproof CP-3 valve is a normally closed (NC) valve that is controlled from a remote location by means of compressed air.

To separate the two liquids, the valve has two independent plug seals. The space between the two seals forms an atmospheric vent chamber. When the valve is open, the chamber is closed. The product can then flow from one line to the other without spillage. The valve can easily be cleaned and protected against the effects of water hammer according to the specific requirements of the process and the configuration of the valve.

Possible configurations

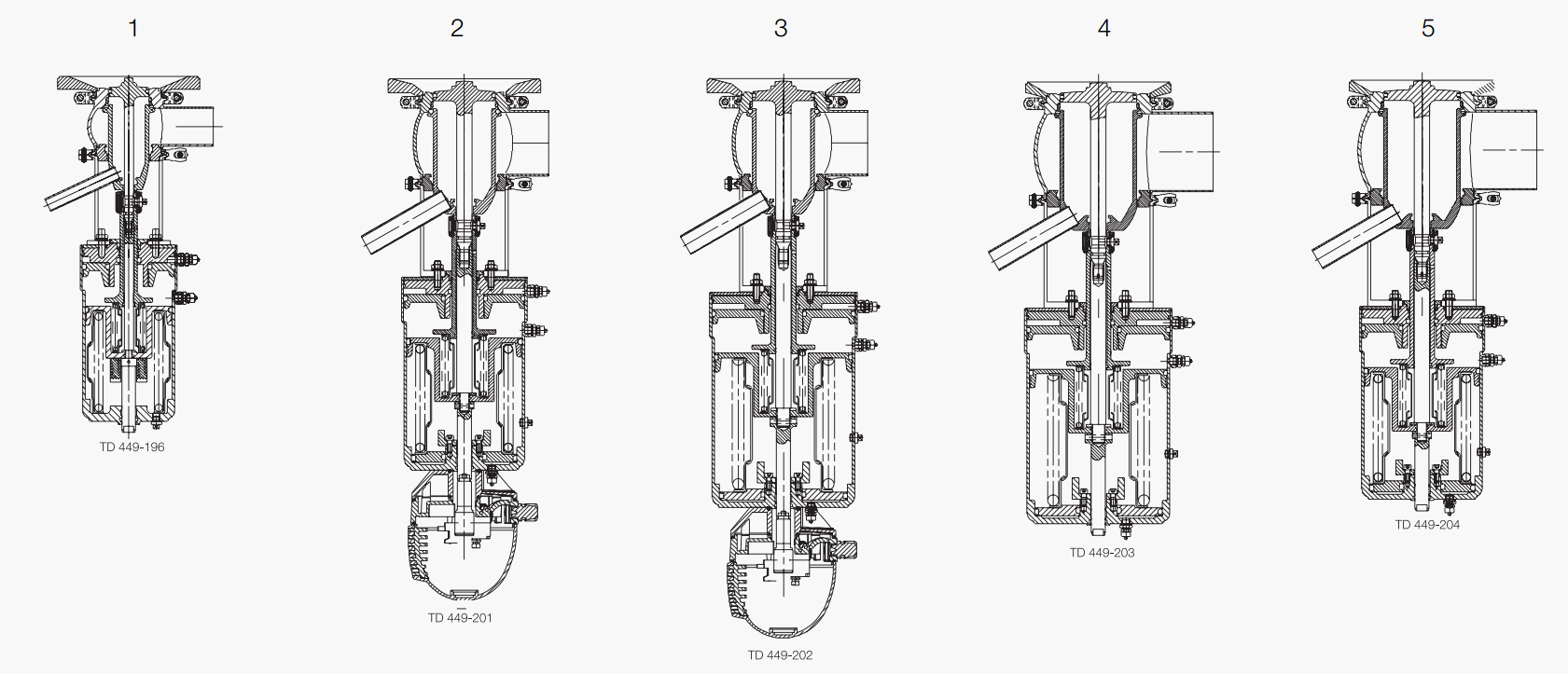

The Alfa Laval Unique Mixproof CP-3 offers a wide range of options, including:

Lower flush

The Alfa Laval lower flush option ensures CIP of the lower sealing element and the OD of the lower plug during seat push. This option efficiently cleans the lower seal in the housing without the need for external CIP connections, supporting continuous processing.

Balancing flexibility

The Unique Mixproof CP-3 valve has a lower balanced plug to avoid product mix, even in the event of pressure spikes in the system. The upper plug can be configured with or without a balancer depending on the required performance.

SpiralClean

The Alfa Laval SpiralClean system makes it possible to clean the upper and lower plugs and leakage chamber by external CIP connections. The

system cleans more efficiently, uses less cleaning fluid by ensuring that a directional flow of CIP fluid reaches all the surfaces in much less time than with conventional systems.

Spiral Clean of the leakage chamber is not depending on a special type of plug configuration, but can be added to any of the available plug configurations.

Size flexibility (mixed housing)

The valve body can be configured with mixed sizes. The body sections can be fully combined, including the full range of 1-1/2″ through 6″ sizes.

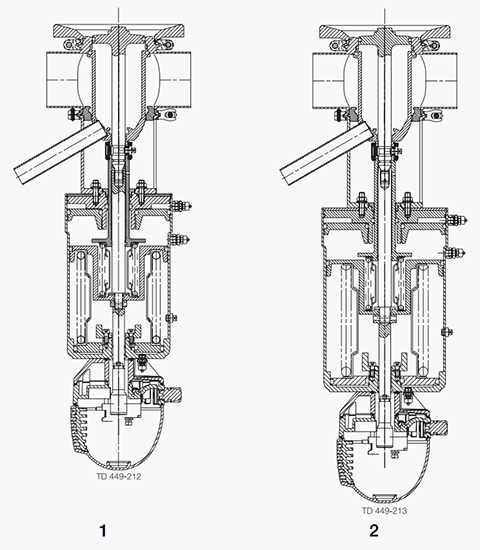

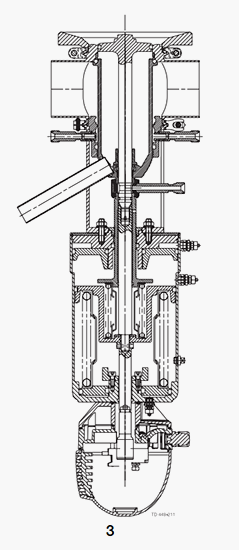

Seat lift and Seat push

Seat lift and seat push enable cleaning of the plug seals of either the upper or lower plug individually. The Unique Mixproof CP-3 range is available in a variety of configurations, including two separate actuator versions. An actuator with both upper seat lift and lower seat push or an actuator without any seat lift/push operations only one period.

The Unique Mixproof CP-3 modular range offers balanced and unbalanced plugs, seat lift/push, CIP for the plugs and leakage chambers and any combination in between.

|

Actuator with both upper and lower seat lift/push operations

3″/3″, 22-00, with lower balanced plug, SpiralClean leakage chamber, actuator with seat lift/push, and external proximity switch for indication of upper plug position

|

|

Actuator without any seat lift/push operations

2″/3″, 22-00, with lower balanced plug, actuator without seat lift/push and external proximity switch for indication of upper plug position

|

Options

-

Tri clamp connections

-

Control and Indication: IndiTop, ThinkTop or ThinkTop Basic(ThinkTop is mandatory in a dairy application)

-

External proximity switch for indication of upper plug position (This option is mandatory in dairy applications)

-

Product wetted seals in HNBR, NBR or FPM

-

Various external surface finishes