Lawrence Pumps

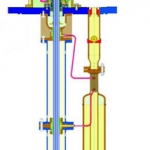

With its rugged ISO 13709/API 610 compliant construction and protected sleeve bearings, the VPL3600 vertical slurry pump is specifically designed for the tough slurry applications found in decoking units.

Numerous Impeller and Casing Designs allows the hydraulics to be tailored to the service requirements.

Lawrence Pumps VPL3600 Slurry Pump

Lawrence Pumps VPL3600 Slurry Pump

| Brand | Description |

|---|---|

| Lawrence Pumps | With its rugged ISO 13709/API 610 compliant construction and protected sleeve bearings, the VPL3600 slurry pump is specifically designed for the tough slurry applications found in decoking units. |

VPL3600 Slurry Pump Application

Residuum and Heavy Oil Upgrading

-

Industries:

Oil and Gas

-

Standards:

API610

Numerous Impeller and Casing Designs allows the hydraulics to be tailored to the service requirements.

Front and Rear Repelling Vanes replace erosion-prone wear rings.

A Sparger System with it’s agitation ring around the pump casing keeps coke particles in suspension to prevent silting-in of the pump. The ring is fed by either water from an outside source or through a filtration system.

Sleeve Bearing Flush System prevents coke fines from entering the column pipe.

Multiple Corrosion- and Abrasion-resistant Materials are available to suit application needs. Hard facing is avaialble on critical shaft areas.

Typical Operating Parameters (custom designs available for limits exceeding those listed)

- Flows to 1500 m3/h (6600 gpm)

- Heads to 150 m (492 ft)

- Speeds to 1800 rpm

VPL1700 Toxic Liquids Vertical Lineshaft Pump

VPL1700 Toxic Liquids Vertical Lineshaft Pump

| Brand: | Lawrence Pumps |

|---|---|

| Description: | The VPL1700 multistage, vertical lineshaft pump is ideal for transfering toxic liquids (e.g., chlorine, phosgene, anhydrous… |

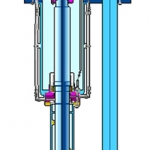

The VPL1700 multistage, vertical lineshaft pump is ideal for transfering toxic liquids (e.g., chlorine, phosgene, anhydrous cyanide and other lethal fluids). Pumps are top-entry, tank-mounted for maximum safety and reliability.

- Applications:

Caustic and Chlor-alkali, Volatile Organic Compounds - Industries:

Chemical Processing

Vertical, Top-Entry Tank Mounting eliminates potentially hazardous side or bottom connections.

A Gas Mechanical Seal provides the lowest fugitive emissions without complex piping, instrumentation or regulation. A complete instrumentation package is available to control the flow of buffer gas to the seal chamber and monitor critical operating parameters.

An Optional Emergency Seal isolates the storage vessel from the atmosphere should a packing or mechanical seal failure occur.

An Optional Excess Flow Check Valve operates independently to stop the flow of liquid chlorine should a downstream line rupture occur while the pump is running.

Numerous Materials of Construction are available to suit application requirements.

The Diffuser Casing Design completely balances the radial thrust. Regardless of the number of stages used, or the head developed by the pump, the radial load carried by the sleeve bearings is minimal.

An Optional Inducer can be added to reduce NPSHR to minimize tank inventory.

Typical Operating Parameters (custom designs available for limits exceeding those listed)

- Flows to 182 m3/h (800 gpm)

- Heads to 244 m (800 ft)

- Temperatures from -51°C (-60°F) to 52°C (125°F)

Lawrence Pumps® VPL1700 Multistage Vertical Toxic Liquid Pump

Lawrence Pumps® VPL1700 Multistage Vertical Toxic Liquid Pump -Mechanical and Hydraulic Upgrades

AFH9000 Axial Flow Elbow Pump

AFH9000 Axial Flow Elbow Pump

| Brand: | Lawrence Pumps |

|---|---|

| Description: | AFH9000 Axial Flow Pump is the ideal choice for low-pressure, high-volume transfer applications, such as those frequently found in chemical and hydrocarbon processing. |

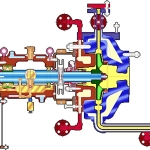

The AFH9000 axial flow elbow pump is ideal for low-pressure, high-volume transfer applications, such as those frequently found in chemical and hydrocarbon processing. Typical applications include evaporators, crystallizers and heat recovery.

Lawrence Pumps Features

-

- Large-diameter cantilevered shafts eliminate the need for internal support bearings in the plumage and minimize deflection at the seal chamber to extend seal life.

- Back pullout design simplifies internal inspection and maintenance of the rotating element without disturbing the piping or motor connections.

- A slinger protects the shaft seal from process solids.

- An optional inflatable shaft seal permits maintenance or inspection of the mechanical seal without draining the entire system.

- It may also act as a stationary emergency seal.

- Numerous options are available to suit application requirements.

Elbow Axial Flow Pump Typical Operating Parameters (custom designs available for limits exceeding those listed)

- Flows to 34 065 m3/h (150 000 gpm)

- Heads to 11 m (36 ft)

- Pressures to 10.3 bar (150 psi)

- Temperatures to 149°C (300°F)

AFH9500 Polyolefin Loop Reactor Pump

AFH9500 Polyolefin Loop Reactor Pump

| Brand: | Lawrence Pumps |

|---|---|

| Description: | Flowserve AFH9500 Pump, is developed specifically for loop reactor circulation, the AFH9500 Polyolefin Reactor is a high-pressure axial flow pump and it delivers increased plant productivity ,earning it a well-earned reputation as the industry’s preferred pump for polyolefin production. |

Developed specifically for loop reactor circulation, the Lawrence Pumps AFH9500 high-pressure axial flow pump boasts a well-earned reputation as the industry’s preferred pump for polyolefin production. Its high-performance propeller design offers plant operators superior process control, while its conservatively engineered bearing and sealing systems provide the reliability required by an unspared pump.

- Applications:

Polymers - Industries:

Chemical Processing

High-Pressure Loop Reactor Pump for Polyethylene Production Features

- High-pressure Elbow Casing is designed, fabricated, and tested per ASME Boiler and Pressure Vessel Code, Section VIII, Division 1 and applicable international standards.

- Propellers are engineered with steep pump head curves to ensure process performance requirements are met while allowing superior process control.

- Tripe Seal Arrangement is standard on large pumps, providing added safety and increased reliability over alternative design.

- API Plan 32/53C/52 seal support systems ensure adequate seal face lubrication and cooling for proper operation.

- Other seal arrangements and support systems are also available.

- Internal Anti-Friction or Sleeve Bearings are self-aligning and support radial and axial loads.

- Cantilevered shafts are typically utilized on pumps with discharge sizes up to 12 inches.

- Standard Flanges are ASME B16.5 or B16.47, Class 600 weld neck, but alternative ratings and type may be specified.

- Custom flanges are also available.

- Drive options include: direct, variable speed, cardan shaft and V-belts.

Typical Operating Parameters (custom designs available for limits exceeding those listed)

- Flows to 18 180 m3/h (80 000 gpm)

- Pressures to 100 bar (1450 psi)

- Temperatures to 349°C (660°F)

- Heads up to 40 m (131 ft)

VPL3400 Engineered Vertical Cantilever Molten Salt Pump

VPL3400 Engineered Vertical Cantilever Molten Salt Pump

| Brand: | Lawrence Pumps |

|---|---|

| Description: | The VPL3400 is designed specifically for molten salt transfer in concentrated solar power plants. Its true cantilever design,… |

The VPL3400 is designed specifically for molten salt transfer in concentrated solar power plants. Its true cantilever design, reliable sealing system and thermal growth tolerance make it ideal for this high-temperature application.

- Applications:

Molten Salt Transfer, Heat Transfer Fluids - Industries:

Power Generation

Custom Engineered Slurry Hydraulics ensure safe, reliable and efficient performance.

Heavy-duty Stainless Steel Construction is typically utilized to equalize thermal growth and resist distortion without an external cooling system. Alternative materials, including carbon steel and nickel-based alloys, are also available to suit service needs.

The Impeller is keyed to the pump shaft and secured using an impeller nut. Clearances are easily adjustable at the thrust bearing location. Repelling vanes reduce wear and recirculation.

Shafts are designed to operate approximately 30% below the first critical speed.

Shaft Sealing is accomplished via packing with a nitrogen purge to prevent fugitive emissions and reduce heat conduction.

Heavy-duty, Anti-friction Thrust and Radial Bearings are located above liquid level and accommodate all axial and radial loads without transmitting any loads to the driver.

Many Options are available to suit site requirements. These include:

- Inducer

- Suction tailpipe

- Basket-type screen

- Several driver types

Typical Operating Parameters (custom designs available for limits exceeding those listed)

- Flows to 4542 m3/h (20 000 gpm)

- Heads to 91 m (300 ft)

- Temperatures to 593°C (1100°F)

VPL3300 Engineered Vertical Cantilever TiCl4 Pump

VPL3300 Engineered Vertical Cantilever TiCl4 Pump

| Brand: | Lawrence Pumps |

|---|---|

| Description: | The VPL3300 is designed specifically for titanium tetrachloride (TiCl4) applications in pigments processing.… |

The VPL3300 is designed specifically for titanium tetrachloride (TiCl4) applications in pigments processing. Its true cantilever design and rugged wet-end construction are ideal for this volatile toxic slurry.

- Applications:

Volatile Organic Compounds - Industries:

Chemical Processing

Custom Engineered Slurry Hydraulics ensure safe, reliable and efficient performance.

High Chrome Iron Wet End resists abrasion. Heavy wall thickness on the wearing parts provides for longevity.

The Impeller is keyed to the pump shaft and secured using an impeller nut. Clearances are easily adjustable at the thrust bearing location. Repelling vanes reduce wear and recirculation.

Shafts are designed to operate approximately 30% below the first critical speed.

Shaft Sealing is accomplished via packing with a nitrogen purge to prevent fugitive emissions.

Heavy-duty, Anti-friction Thrust and Radial Bearings are located above liquid level and accommodate all axial and radial loads without transmitting any loads to the driver.

Many Options are available to suit site requirements. These include:

- Inducer

- Suction tailpipe

- Basket-type screen

- Abrasion- or corrosion-resistant materials of construction

- Several driver types

Typical Operating Parameters (custom designs available for limits exceeding those listed)

- Flows to 4542 m3/h (20 000 gpm)

- Heads to 91 m (300 ft)

- Temperatures to 593°C (1100°F)

VPL3200 Engineered Vertical Cantilever Pump

VPL3200 Engineered Vertical Cantilever Pump

| Brand: | Lawrence Pumps |

|---|---|

| Description: | The VPL3200 is a true cantilever pump, without any submerged bearings, bushings or rings. The highly versatile VPL3200 is… |

The VPL3200 is a true cantilever pump, without any submerged bearings, bushings or rings. The highly versatile VPL3200 is available for sump and sealed tank-mounted applications. It is particularly well-suited for applications where flushing liquids are not available or cannot be tolerated.

- Applications:

Scale Recycle, Slurry Processing, Offsites and Waste Treatment, Auxiliary Services (power), Descaling, Slurry Transfer (mining) - Industries:

Chemical Processing, Mining, Primary Metals, Power Generation, Oil and Gas

Numerous Casing and Impeller Hydraulics are available to precisely fit performance requirements. Configurations include bottom suction, top suction, double-suction, double volute, slurry and non-clogging designs.

The Impeller is keyed to the pump shaft and secured using an impeller nut. Clearances are easily adjustable at the thrust bearing location.

The Shaft prevents is designed to operate approximately 30% below the first critical speed. The pump can operate over the complete capacity-head range without restriction.

Heavy-duty, Anti-friction Thrust and Radial Bearings are located above liquid level and accommodate all axial and radial loads without transmitting any loads to the driver.

Grease Lubrication is standard, although oil mist, forced oil, or internally circulated self-contained oil lube systems are available.

Dry-run capability with no adverse affects.

Many Options are available to suit site requirements. These include:

- Inducer

- Suction tailpipe

- Mechanical or hydraulic agitation

- Basket-type screen

- Abrasion- or corrosion-resistant materials of construction

- Several driver types

Typical Operating Parameters (custom designs available for limits exceeding those listed)

- Flows to 4542 m3/h (20 000 gpm)

- Heads to 91 m (300 ft)

- Temperatures to 593°C (1100°F)

HPX6000 and HPXM6000 Fully Lined API Slurry Pumps

HPX6000 and HPXM6000 Fully Lined API Slurry Pumps

| Brand: | Lawrence Pumps |

|---|---|

| Description: | By using the “pump within a pump” concept, the HPX6000 and HPXM6000 fully lined slurry pumps reliably and safely handle abrasive… |

By using the “pump within a pump” concept, the HPX6000 and HPXM6000 fully lined slurry pumps reliably and safely handle abrasive solids at elevated temperatures without the danger of pump casing erosion.

- Applications:

Catalytic Cracking, Gas to Liquids, Heavy Oil, Oil Sands and Shale, Offsites and Waste Treatment, Residuum and Heavy Oil Upgrading, Slurry Transfer (mining) - Industries:

Mining, Oil and Gas - Standards:

API610

Replaceable Mechanically Fastened Liners completely protect the pressure casing from erosion and abrasion. The cost of replacing the renewable liners is only a fraction of the replacement or repair cost of a coated ISO/API pump pressure casing.

Casing Penetrations, including the vent and drain, are protected from the effects of erosion by the renewable liners. Flanges can be machined to most client specifications.

Casing Liners are available in multiple abrasion-resistant materials and surface treatments to meet any process or operational requirement. Pressure casings are available in a variety of materials, including steel, stainless steel, CA6NM and duplex.

Multiple hydraulic sizes are available for each HPX6000 pressure shell. By changing the casing liner and impeller, pump performance can be altered without modification to the piping or foundations.

Front and Rear Repelling Vanes on the HPX6000 replace erosion-prone wear rings.

Barske-style Impeller and matching volute allows the HPXM6000 to operate at low flows near BEP while minimizing radial loads.

Inducers are available for low-NPSHA applications.

Lawrence Pumps® HPX6000 Fully Lined API Slurry Pump

Lawrence Pumps® HPX6000 Fully Lined API Slurry Pump – ISO 13709/API 610 (OH2)

HPXM6000 Fully Lined Low-Flow

Flowserve HPXM6000 Fully Lined Low-Flow – Hydrocarbon Processing Slurry Pump

HPX1800 ISO 13709/API 610 (OH2) Jacketed Process Pump

HPX1800 ISO 13709/API 610 (OH2) Jacketed Process Pump

| Brand: | Lawrence Pumps |

|---|---|

| Description: | The HPX1800 jacketed process pump is designed to reliably transfer molten sulfur and other chemicals where temperature control… |

The HPX1800 jacketed process pump is designed to reliably transfer molten sulfur and other chemicals where temperature control is critical.

- Applications:

Gas Treating and Sulfur Recovery - Industries:

Oil and Gas - Standards:

API610

Unique Integral Jacket Design completely encompasses the wet end, ensuring even heating and protection against cold spots. The integral design is more efficient and reliable than bolt-on jackets.

Casings can be fully inspected and hydrotested before the jackets are welded in place.

The Sealing System is specifically designed to prevent the solidification in the seal face area. Seal chambers are designed to accept a broad range of mechanical seal configurations.

Back Pull-out Design simplifies internal inspection and maintenance by allowing removal of the entire rotating element and bearing frame without disturbing the piping or motor.

Inducers are available for low-NPSHA applications.

Typical Operating Parameters (custom designs available for limits exceeding those listed)

- Flows to 1816 m3/h (8000 gpm)

- Heads to 213 m (700 ft)

- Pressures to 62 bar (900 psi)

- Temperatures to 371°C (700°F)