Contact us today to learn more about the IDP WXM Between Bearings Pump and optimize your system’s performance!

IDP

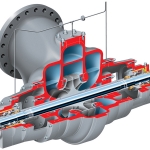

Radially Split Pressure Casings are positively located by interstage rabbet fits, ensuring overall pump concentricity and rotor alignment. Non-shear, compression-type O-rings positively seal channel rings.

Precision-cast Diffusers create symmetrical passageways around the impellers to equalize radial loads, resulting in increased bearing, wear ring and seal life plus tolerance to transient conditions.

Heavy-duty Rotor with short bearing spans minimizes deflection and prolongs bearing and seal life. Tight tolerances and precision fit impellers ensure proper clearance, concentricity and runout.

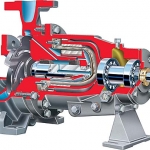

WCC Between Bearings Pump

WCC Between Bearings Pump

The WCC is a multistage, diffuser-type barrel pump that uses a tandem or opposing impeller rotor and a single-diameter balancing drum to compensate for residual axial thrust.

With a spare, the conventional cartridge-type design enables for rapid changeout, reducing lost production. The WCC Between Bearings Pump is the optimum option when process requirements necessitate a versatile, low-cost solution that is also fully compatible with API 610/ISO 13709 standards. Its wide range of features and metallurgical capabilities allow it to meet almost every oil and gas requirement.

The WCC pump is a general-purpose barrel pump that is CE and ATEX certified and conforms to the most recent standard of ISO 13709/API 610 (BB5). According to the ASME Pressure Vessel Code Section VIII, Div. 1, pressure-containing elements are:

Flowserve engineers will also assist users in addressing and including site-specific needs, while, at the very least, meeting minimum standards for:

• Mechanical seals comply with ISO 21049/API 682

• API 610 or 614 lubricating systems.

The rotor can be designed “in-line” or if necessary, as a “opposed impeller.” Just the proper cast. Impellers with circular flow patterns. Individually balanced up to G2.5. Just one suction. Some lower sizes have first-stage impellers, while larger sizes have double force. Impellers come with worn rings, which can be replaced on the front and back hubs as usual. The overlay material should be chosen according to the application, and DLD is the optimum method for applying a hard covering formed of super duplex materials.

As an alternative, full worn surfaces can be delivered. The typical approach to construct a rotor is to use a stepped shaft and shrink-fit impellers that are keyed to each shaft separately. When there is an axial force on the shaft shoulder, the impellers are held in place and cannot move in that direction. A split band can be used to prevent impellers from moving in the opposite direction of the thrust when necessary.

Specification :

- ISO 13709 / API 610

- Hydraulic Institute

- Customer specifications

- Flows: 1000 m3/hr (4400 gpm)

- Head: 4000 m (13000 ft)

- Pressure: 300 bar (4350 PSI)

- Temperature: -73°C to 425°C (-100°F to 800°F)

- Flange ratings: 600# up to 2500#

- 6 sizes with discharges from 2? to 10? existing of 44 hydraulics

Size Range: 4 Sizes (3” to 8”) with 18 available hydraulics

WCC Between Bearings Pump for High-Performance Applications

- Water or CO2 injection

- Pipeline

- Amine feed

- Hydrocarbon charge

- Ethylene feed

- Acid gas reinjection

- Hydraulic power recovery turbine

- Boiler feedwater

Configurations :

- WCCD (Double Suction)

- WCCO (Opposed impeller configuration)

- WCC-T (Hydraulic turbine)

- WCC-TT (True turbine)

Industries :

- Power

- Nuclear

- Conventional Steam

- Combined Cycle

- Geothermal

- Chemicals

- Basic (Organic & Inorganic)

- Specialty (Fine & Consumer)

- Biofuels

- Pharmaceutical

- Petrochemicals

- Oil & Gas

- Upstream Exploration & Production

- Midstream Transportation

- Downstream Processing

Water Injection Pumps – Brochure

Oil and Gas Barrel Pumps – Brochure

WCC Between Bearings Pump General Purpose Barrel Pump or the Oil and Gas Industry – Brochure

Flowserve Pump Product Portfolio

Contact us now to learn more about the IDP WCC Between Bearings Pump and enhance your industrial performance!

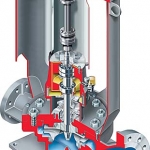

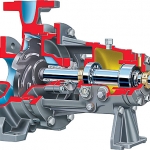

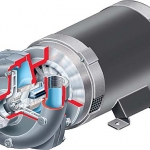

WXM Between Bearings Pump

WXM Between Bearings Pump

The IDP WXM Between Bearings Pump has a segmental ring, medium pressure diffuser design. A device for axial thrust balance with a multilayer rotor construction. Suitable for boiler feed pump applications in biomass, solar energy, steam generation and industrial boiler projects.

IDP WXM Pump for Power and Water Management Applications

- More reliability from radially split pressure casings ensures rotor alignment and overall pump concentricity.

- Precision-cast diffusers that equalise radial stresses while increasing bearing, wear ring, and seal life, hence boosting service life and adaptability to changing conditions.

- Longer service intervals and lower maintenance costs, enabled by a heavy-duty rotor with short bearing spans, help to reduce deflection.

- The modular segmental ring diffuser design allows for a perfect hydraulic arrangement, as well as various other options.

Industries :

- Power

- Conventional Steam

- Combined Cycle

- Concentrated Solar Power (CSP)

- Biomass & MSW

- Geothermal

- Water

- Water Management

- Oil & Gas

- Downstream Processing

- General Industries

- Other Industries

Specification:

- Flowserve

- Hydraulic Inst.

- Flows to 1250 m3/h (5500 gpm)

- Heads to 800 m (2600 ft)

- Pressures up to 180 bar (2610 psi)

Size Range: 3″ to 6″ 75mm to 150mm

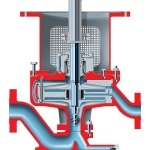

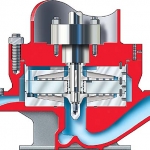

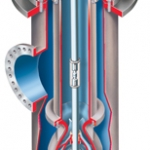

WXH Between Bearing, Radially Split, Multistage, Ring Section Pump

WXH Between Bearing, Radially Split, Multistage, Ring Section Pump

| Brand: | IDP |

|---|---|

| Description: | The WXH pump is a horizontal, radially split, high-pressure, ring section pump. It is particularly well-suited for boiler… |

The WXH pump is a horizontal, radially split, high-pressure, ring section pump. It is particularly well-suited for boiler feedwater on large industrial boilers and in combined cycle plants where severe cycling operation is commonplace.

- Applications:

Descaling, Boiler Feed - Industries:

Power Generation, Primary Metals

Radially Split Pressure Casings are positively located by interstage rabbet fits, ensuring overall pump concentricity and rotor alignment. Non-shear, compression-type O-rings positively seal channel rings.

Precision-cast Diffusers create symmetrical passageways around the impellers to equalize radial loads, resulting in increased bearing, wear ring and seal life plus tolerance to transient conditions.

Heavy-duty Rotor with short bearing spans minimizes deflection and prolongs bearing and seal life. Tight tolerances and precision fit impellers ensure proper clearance, concentricity and runout.

First-stage Impellers may be single- or double-section design, depending upon NPSH available.

Self-adjusting Flanged Balance Drum eliminates residual axial thrust across the operating range.

Operating Parameters

- Flows to 900 m3/h (4000 gpm)

- Heads to 2650 m (8700 ft)

- Pressures to 310 bar (4500 psi)

- Temperatures to 250°C (480°F)

Concentrated Solar Power Pumps

Flowserve Pumps for Concentrated Solar Power – Parabolic Trough – Power Tower

Power Generation Pumps

WXH Pump Poster

Flowserve WXH Pumps – Between Bearings, Radially Split, Multistage Ring Section Pump

Flowserve WXH Pump

Flowserve WXH – Between Bearings – Radially Split – Multistage Ring Section Pump

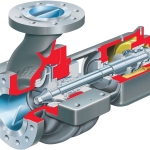

HPX ISO 13709/API610 (OH2) Hydrocarbon Processing Pump

HPX ISO 13709/API610 (OH2) Hydrocarbon Processing Pump

| Brand: | IDP |

|---|---|

| Description: | Engineered and built for reliable, safe performance, the HPX also provides optimal emissions containment. This pump represents… |

Engineered and built for reliable, safe performance, the HPX also provides optimal emissions containment. This pump represents the most comprehensive range of hydraulic coverage available to the industry, thereby permitting precise selection for best operating efficiency.

- Applications:

Digester, Solvents, Distillation (oil and gas), Water Supply and Treatment (oil and gas), Drilling and Production, Water and CO2 Injection, Flue Gas Desulfurization, FPSO, Gas Treating and Sulfur Recovery, Gas to Liquids, Heat Transfer Fluids, Heavy Oil, Oil Sands and Shale, Acid Transfer, Hydrocracking, Boiler Feed Booster, Hydrotreating, Catalytic Cracking, LNG, Caustic and Chlor-alkali, Leaching Acid, Cooling Water (power), Chemical and Liquor (pulp and paper), Plating, Galvanizing and Other Coatings, Crude, Product and CO2 Pipeline, Residuum and Heavy Oil Upgrading, Desalination, Volatile Organic Compounds - Industries:

Primary Metals, Pulp and Paper, Water Resources, Power Generation, Mining, Oil and Gas, Chemical and Liquor - Standards:

API682, API610

Centerline Supported Pump Casing withstands nozzle loads beyond ISO 13709/API 610 design requirements and minimizes shaft misalignment, extending rotor, bearing and seal life.

Suction Nozzle Guide Vane reduces inlet vortexing and ensures uniform flow into the impeller to achieve a reliable NPSH margin.

Precision Cast Impeller is dynamically balanced to limit vibration and assure smooth operation over wide flow range.

Raised Face Flanges are to ASME B16.5 criteria for Class 300 or 600. Surface finish meets ISO 13709/API 610 standards. ISO and JIS flanges are available.

Renewable Wear Rings for both the casing and impeller reduce replacement part costs.

ISO 21049/API 682 Seal Chamber accommodates a wide variety of seal configurations.

Operating Parameters

- Flows to 2000 m3/h (8800 gpm)

- Heads to 350 m (1100 ft)

- Pressures to 80 bar (1160 psi)

- Temperatures from -160°C (-250°F) to 450°C (840°F)

RVX Pump Upgrade Bulletin

Flowserve RVX Pump Upgrade – ISO 13709/API 610 Back Pull-out Retrofit

HPXM Pump Bulletin

Flowserve HPXM Pumps – ISO 13709/API 610 (OH2), Centerline Mounted, Low-Flow, High-Head, Overhung Process Pump

HPX-H Pump Bulletin

Flowserve HPX-H Pumps – ISO 13709/API 610 (OH2) – High-Pressure Horizontal Process Pump

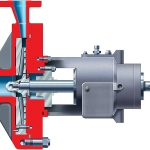

HDX ISO 13709/API 610 (BB2) Between Bearings, Single Case, Radially Split, Single Stage Double Suction Pump

HDX ISO 13709/API 610 (BB2) Between Bearings, Single Case, Radially Split, Single Stage Double Suction Pump

| Brand: | IDP |

|---|---|

| Description: | The HDX pump bridges the flow and pressure disparity between overhung and multistage process pump lines. Fully compliant… |

The HDX pump bridges the flow and pressure disparity between overhung and multistage process pump lines. Fully compliant with the latest ISO 13709/API 610 (BB2) standards, the HDX is engineered for safe, reliable performance at the elevated temperatures and pressures of refining and power applications.

- Applications:

Nuclear Service, Hydrotreating, Offsites and Waste Treatment, Residuum and Heavy Oil Upgrading, Dewatering and Water Supply (mining), Water and CO2 Injection, Industrial Gases, LNG, Auxiliary (chemical), Water Supply and Distribution (water), Catalytic Cracking, Distillation (oil and gas), FPSO, Gas to Liquids, Heat Transfer Fluids, Heavy Oil, Oil Sands and Shale, Hydrocracking, Boiler Feed Booster, Boiler Feed (pulp and paper) - Industries:

Power Generation, Pulp and Paper, Oil and Gas, General Industries, Mining, Water Resources - Standards:

API682, API610

Dual Volute Centerline Supported Casing, combined with a stiff shaft design, ensures full compliance with ISO 13709API 610 specified nozzle loads, vibration and shaft run-out requirements.

Double Casing Covers provide easy maintenance.

Double Suction Impeller minimizes thrust problems, reduces NPSH requirements and allows mechanical seals to operate at equal and low pressure.

Dynamically Balanced Rotor ensures smooth operation for longer mechanical seal and bearing life. TIR Verifications ensure optimum mechanical performance throughout the operating range.

360° Support Bearing Housings are made of carbon steel to provide added stiffness and reduced vibration.

ISO 21049/API 682 seal chamber accommodates a wide variety of seal configurations.

High Pressure model (HPX-H) available.

Operating Parameters

- Flows to 4100 m3/h (18 000 gpm)

- Heads to 450 m (1500 ft)

- Pressures to 42 bar (610 psi); 100 bar (1450 psi) with HDX-H model

- Temperatures to 450°C (850°F)

Concentrated Solar Power Pumps

Flowserve Pumps for Concentrated Solar Power – Parabolic Trough – Power Tower

Nuclear Power Pumps

Flowserve Pumps for Nuclear Power – Pumps – Seals – Engineering and Technical Support – Re-rates and Upgrades – Aftermarket Services

HDX Pump Bulletin

Flowserve HDX Pumps – ISO 13709/API 610 (BB2) Radially Split, Double Suction Process Pump

HWX Overhung Pump API 610 OH3

The HWX Overhung Pump is fully compliant with the most recent iteration of API 610 OH3 and is designed vertically in-line. This pump serves as a space-saving alternative for numerous overhanging process pumps in upstream and downstream operations, as well as high-temperature, low-temperature and high-operating pressure systems.

HWX Overhung Pump

The Flowserve HWX Overhung Pump is a vertical, in-line design, fully compliant with API 610 OH3, latest edition. This pump offers a space-saving alternative for many overhung process pumps in upstream and downstream services, including cryogenic, high temperature, and high working pressure services.

-

Applications:

Hydrocarbon Processing, Lubricating Oil, High Temperature Service, Hydrocarbon Booster, General Purpose, Gas Industry Service , Gas Production, Fuel, Flammable Liquids, Diesel Fuel, Boiler Circulation, Water, Synthetic Fuels, Petroleum Distribution, Petrochemical Processing, Lube Oil Transfer and Feed, Gasoline, Light Oils, Petroleum Production and Refining

-

Industries:

Crude Handling and Treatment, Catalytic Cracking, Hydrocraking, Utilities, SAGD, NGL, Delayed Coking, LNG, Hydrotreating, Water Handling and Treatment, Gas Treatment, Gas-to-Liquids, Distillation, Logistics and Tank Farm

-

Standards:

API610

Space Saving Design engineered for safe, reliable performance in cryogenic, high temperature and high working pressure services.

API 682 Seal Chamber accommodates a wide variety of seal configurations including dual pressurized and unpressurized cartridge types for the most severe services. A full complement of API 610 seal flush plans is available.

Stiff Shaft Design limits maximum deflection at seal faces to 0.05 mm (0.002 in). Shaft stiffness factors (L3/D4) are best in the industry.

Dynamically Balanced Impeller limits vibration and ensures smooth operation over wide flow range.

Accommodates NEMA, IEC and existing field drivers (C-face and P-base).

Features:

- Bearing lubrication options

- Oil cascade

- Oil mist

- Grease lube

- Options

- Inpro top bearing isolator

- Inducer for low NPSH requirements

- Double suction impeller

- Other configurations

- HWM (OH3, low flow, high head, single stage)

- HWM-2 (OH3, low flow, high head, 2-stage)

- Operating parameters

- Flows to 1500 m3/h (6600 gpm)

- Heads to 300 m (1000 ft)

- Pressures to 80 bar (1160 psi)

- Temperatures from -160°C (-250°F) to 400°C (750°F)

WMA2 Two Stage, Rigidly Coupled, Vertical In-line, Low-Flow, High-Head Process Pump

WMA2 Two Stage, Rigidly Coupled, Vertical In-line, Low-Flow, High-Head Process Pump

| Brand: | IDP |

|---|---|

| Description: | The WMA2 is a two stage rigidly coupled pump designed to comply with API requirements for OH4 pumps. Like the HWMA2 pump,… |

The WMA2 is a two stage rigidly coupled pump designed to comply with API requirements for OH4 pumps. Like the HWMA2 pump, the high head hydraulics of the WMA2 are achieved using back-to-back, radial blade impellers and 2-pole P-base motors without high speed gear boxes.

- Applications:

Distillation (oil and gas), Solvents, Drilling and Production, Water Supply and Treatment (oil and gas), FPSO, Water and CO2 Injection, Gas Treating and Sulfur Recovery, Gas to Liquids, Heat Transfer Fluids, Heavy Oil, Oil Sands and Shale, Acid Transfer, Hydrocracking, Boiler Feed Booster, Hydrotreating, Catalytic Cracking, Industrial Gases, Caustic and Chlor-alkali, LNG, Chemical and Liquor (pulp and paper), Leaching Acid, Cooling Water (power), Crude, Product and CO2 Pipeline, Plating, Galvanizing and Other Coatings, Residuum and Heavy Oil Upgrading, Digester, Volatile Organic Compounds - Industries:

Chemical Processing, Power Generation, Oil and Gas, General Industries - Standards:

API682, API610

Replaceable Volute Insert permits precise hydraulic customization. Each insert is engineered for specified head and flow requirements. Accommodates future system changes.

Rigid Coupling ensures precision shaft alignment, thus eliminating time-consuming manual alignment.

Casing and Cover feature metal-to-metal fits with fully confined, controlled compression gasket to ensure proper sealing and alignment.

Raised Face Flanges are to ASME B16.5, Class 300 for one stage and Class 600 for two stage models.

ISO 21049/API 682 Seal Chamber accommodates a wide variety of seal configurations including dual pressurized and unpressurized cartridge types for the most severe services.

Stiff Shaft Design limits deflection at seal faces to 0.05 mm (0.002 in) max. Vibration levels are well below that required by ISO 13709/API 610.

Operating Parameters

- Flows to 45 m3/h (200 gpm)

- Heads to 440 m (1445 ft)

- Pressures to 60 bar (850 psi)

- Temperatures to 260°C (525°F)

WMA2 centrifugal pumps User Instructions

Installation, Operation, and Maintenance for 2 Stage, Vertical inline Pumps

HWMA Pump Bulletin

Flowserve HWMA Pumps – Low-Flow, High-Head, Vertical In-line Process Pump With Bearing Housing – ISO 13709/API 610 (OH3) – HWMA2, WMA and WMA2 models included.

WMA ISO 13709/API 610 (OH4) Rigidly Coupled, Vertical In-line, Low-Flow, High-Head Process Pump

WMA ISO 13709/API 610 (OH4) Rigidly Coupled, Vertical In-line, Low-Flow, High-Head Process Pump

| Brand: | IDP |

|---|---|

| Description: | The WMA is a rigidly coupled, ISO 13709/API 610 OH4 design vertical in-line pump and features the same hydraulics as the… |

The WMA is a rigidly coupled, ISO 13709/API 610 OH4 design vertical in-line pump and features the same hydraulics as the HWMA. The WMA uses a P-base motor and is shorter in height than the ISO 13709/API 610 OH3 design of the HWMA.

- Applications:

Catalytic Cracking, Hydrotreating, Caustic and Chlor-alkali, LNG, Chemical and Liquor (pulp and paper), Leaching Acid, Cooling Water (power), Crude, Product and CO2 Pipeline, Plating, Galvanizing and Other Coatings, Residuum and Heavy Oil Upgrading, Digester, Solvents, Volatile Organic Compounds, Distillation (oil and gas), Drilling and Production, Water Supply and Treatment (oil and gas), FPSO, Water and CO2 Injection, Gas Treating and Sulfur Recovery, Gas to Liquids, Heat Transfer Fluids, Heavy Oil, Oil Sands and Shale, Acid Transfer, Hydrocracking, Boiler Feed Booster, Industrial Gases - Industries:

Chemical Processing, Power Generation, Oil and Gas, General Industries - Standards:

API610, API682

Replaceable Volute Insert permits precise hydraulic customization. Each insert is engineered for specified head and flow requirements. Accommodates future system changes.

Rigid Coupling ensures precision shaft alignment while eliminating time-consuming manual alignment.

Casing and Cover feature metal-to-metal fits with fully confined, controlled compression gasket to ensure proper sealing and alignment.

Raised Face Flanges are to ASME B16.5, Class 300 for one stage and Class 600 for two-stage models.

ISO 21049/API 682 Seal Chamber accommodates a wide variety of seal configurations including dual pressurized and unpressurized cartridge types for the most severe services.

Stiff Shaft Design limits deflection at seal faces to 0.05 mm (0.002 in) max. Vibration levels are well below that required by ISO 13709/API 610.

Operating Parameters

- Flows to 45 m3/h (200 gpm)

- Heads to 220 m (725 ft)

- Pressures to 50 bar (750 psi)

- Temperatures to 260°C (525°F)

HWMA Pump Bulletin

Flowserve HWMA Pumps – Low-Flow, High-Head, Vertical In-line Process Pump With Bearing Housing – ISO 13709/API 610 (OH3) – HWMA2, WMA and WMA2 models included

HWMA ISO 13709/API 610 (OH3) Vertical In-line, Low-Flow, High-Head Overhung API Process Pump

HWMA ISO 13709/API 610 (OH3) Vertical In-line, Low-Flow, High-Head Overhung API Process Pump

| Brand: | IDP |

|---|---|

| Description: | The HWMA is a single stage, vertical in-line overhung pump with a separate bearing bracket. With its small footprint, this… |

The HWMA is a single stage, vertical in-line overhung pump with a separate bearing bracket. With its small footprint, this low flow, high head process pump is a space-saving alternative to many overhung process pumps in upstream and downstream services.

- Applications:

Heat Transfer Fluids, Gas to Liquids, Acid Transfer, Hydrogen, Boiler Feed Booster, Hydrotreating, Catalytic Cracking, LNG, Caustic and Chlor-alkali, Leaching Acid, Chemical and Liquor (pulp and paper), Cooling Water (power), Plating, Galvanizing and Other Coatings, Residuum and Heavy Oil Upgrading, Solvents, Digester, Volatile Organic Compounds, Distillation (oil and gas), Water Supply and Treatment (oil and gas), Drilling and Production, Water and CO2 Injection, FPSO, Gas Treating and Sulfur Recovery, Heavy Oil, Oil Sands and Shale - Industries:

Oil and Gas, Power Generation, Primary Metals, Mining, Chemical Processing, General Industries, Pulp and Paper - Standards:

API682, API610

Replaceable Volute Insert permits precise hydraulic customization. Each insert is engineered for specified head and flow requirements. Accommodates future system changes.

Casing and Cover feature metal-to-metal fits with fully confined, controlled compression gasket to ensure proper sealing and alignment.

Raised Face Flanges are to ASME B16.5, Class 300 for one stage and Class 600 for two stage models.

ISO 21049/API 682 Seal Chamber accommodates a wide variety of seal configurations including dual pressurized and unpressurized cartridge types for the most severe services.

Stiff Shaft Design limits deflection at seal faces to 0.05 mm (0.002 in) max. Vibration levels are well below that required by ISO 13709/API 610.

Heavy-Duty Motor Support Head features a registered fit motor mount and does not use spacer plates.

Operating Parameters

- Flows to 45 m3/h (200 gpm)

- Heads to 220 m (725 ft)

- Pressures to 60 bar (870 psi)

- Temperatures to 260°C (500°F)

HWMA Pump Bulletin

Flowserve HWMA Pumps – Low-Flow, High-Head, Vertical In-line Process Pump With Bearing Housing – ISO 13709/API 610 (OH3) – HWMA2, WMA and WMA2 models included.

CPX ISO Overhung, Single Stage Process Pump

CPX ISO Overhung, Single Stage Process Pump

| Brand: | IDP |

|---|---|

| Description: | Conforming to ISO 2858 dimensional and ISO 5199 design criteria and incorporating advanced features, the CPX chemical process… |

Conforming to ISO 2858 dimensional and ISO 5199 design criteria and incorporating advanced features, the CPX chemical process pump provides unmatched performance and reliability. This ruggedly designed pump offers significant operational and maintenance enhancing benefits to minimize the total cost of pump ownership.

- Applications:

Agriculture, Shipping, Slurry Processing, Acid Transfer, Electronics, Volatile Organic Compounds, Waste Processing, FPSO, Water Supply and Distribution (water), Gas Treating and Sulfur Recovery, Water Supply and Treatment (oil and gas), Water Treatment, HVAC, Heavy Oil, Oil Sands and Shale, Automotive, Hydraulic Press (metals), Pharmaceuticals, Auxiliary (chemical), LNG, Polymers, Auxiliary Services (power), Leaching Acid, Bleach Chemical (pulp and paper), Nuclear Service, Solvents, Chemical and Liquor (pulp and paper), OEM, Caustic and Chlor-alkali, Coatings (pulp and paper), Offsites and Waste Treatment, Food Processing, Construction, Plating, Galvanizing and Other Coatings, Cooling Water (metals), Renewable Fuel Production, Sewage Collection and Treatment, Dewatering and Water Supply (mining), Drilling and Production - Industries:

Chemical Processing, General Industries, Pulp and Paper, Power Generation, Mining - Standards:

ISO

Advanced 45° Conical Seal Chamber with integral vortex flow modifiers increases mechanical seal life.

Standard Non-Contacting Labyrinth Seals keep lubricants in and contaminants out.

Heavy-Duty Pump End and Drive End Bearings selected for long life and reliability.

Heavy-Duty Casing with integral foot and multi-ribbed discharge flange provides superior resistance to pipe loads and improves reliability.

External Three Bolt Rotor Adjustment allows impeller clearances to be reset in situ, thereby restoring head and efficiency.

One-Piece, Ductile Iron Bearing Housing is designed for maximum strength and safety as well as tight concentricity and alignment.

Back Pullout Design allows removal of rotating element without removing casing, piping or motor.

Operating Parameters

- Flows to 1400 m3/h (6160 gpm)

- Heads to 220 m (720 ft)

- Pressures to 25 bar (365 psi)

- Temperatures from -80C (-110F) to 350C (660F)

CPX Pump Bulletin

Flowserve CPX Pumps – ISO Chemical Process Pumps – CPX, CPXS, CPXM, CPXP, CPXR, CPXV

CPX, CPXR, CPXN and CPXP Pump User Instructions

Installation, Operation, and Maintenance Instructions for Single stage, end suction, centrifugal, chemical process pumps (Based on C937KH013, C937KH054, C961KH001 and C937KH067)

CPXV ISO and API Chemical Sump Pump

CPXV ISO and API Chemical Sump Pump

| Brand: | IDP |

|---|---|

| Description: | Compliant with ISO 5199, the CPXV is a vertical sump pump incorporating state-of-the-art hydraulic design for efficient and… |

Compliant with ISO 5199, the CPXV is a vertical sump pump incorporating state-of-the-art hydraulic design for efficient and reliable service. It is highly customizable to meet a wide range of needs. And, for oil and gas installations, the CPXV is available with many ISO 13709/API 610 compliant features.

- Applications:

Automotive, Polymers, Auxiliary Services (power), Electronics, Food Processing, HVAC, OEM, Pharmaceuticals, Renewable Fuel Production, Sewage Collection and Treatment, Shipping, Slurry Processing, Water Supply and Treatment (oil and gas), Water Treatment, Solvents, Acid Transfer, Agriculture, Caustic and Chlor-alkali, Auxiliary (chemical) - Industries:

Chemical Processing, General Industries, Water Resources, Power Generation, Oil and Gas - Standards:

API610, ISO

Standard Front Vane Open-style Impeller design delivers high-efficiency performance. Reverse vane impeller is available.

Additional Column Lengths are provided up to a maximum of 10 m (32 ft).

Heavy-duty Thrust Bearings with axial adjustment made above soleplate level.

Recessed Impeller version is available for enhanced solids-handling capability.

Fully Jacketed version is available for molten sulfur applications.

Molten Salt design is also available.

Operating Parameters

- Flows to 1400 m3/h (6160 gpm)

- Heads to 250 m (820 ft)

- Pressures to 25 bar (365 psi)

- Temperatures from -40°C (-40°F) to 400°C (752°F)

CPXV and CPXRV User Instructions

Installation, Operation, & Maintenance Instructions for Centrifugal, modular design, vertical sump pumps (Based on C942KH001, C942KH021 and C942KH017 User Instructions)

CPX Pump Bulletin

Flowserve CPX Pumps – ISO Chemical Process Pumps – CPX, CPXS, CPXM, CPXP, CPXR, CPXV

CPXV fitted with Mark 3 end suction hydraulics User Instructions

Installation, Operation, & Maintenance instructions for centrifugal, modular design, vertical sump pumps

CPXV fitted with WW/CW hydraulics User Instructions

Installation, Operation, & Maintenance instructions for Centrifugal, modular design, vertical sump pumps

HPXM ISO 13709/API 610 (OH2) Low Flow, High Head Horizontal Process Pump

HPXM ISO 13709/API 610 (OH2) Low Flow, High Head Horizontal Process Pump

| Brand: | IDP |

|---|---|

| Description: | Fully compliant with ISO 13709/API 610 (OH2), latest edition, the HPXM is specifically designed for low flow, high head process… |

Fully compliant with ISO 13709/API 610 (OH2), latest edition, the HPXM is specifically designed for low flow, high head process applications.

- Applications:

Solvents, Residuum and Heavy Oil Upgrading, Volatile Organic Compounds, Digester, Water Supply and Treatment (oil and gas), Distillation (oil and gas), Water and CO2 Injection, Drilling and Production, FPSO, Gas Treating and Sulfur Recovery, Gas to Liquids, Heat Transfer Fluids, Heavy Oil, Oil Sands and Shale, Acid Transfer, Hydrocracking, Boiler Feed Booster, Hydrotreating, Catalytic Cracking, LNG, Caustic and Chlor-alkali, Leaching Acid, Chemical and Liquor (pulp and paper), Cooling Water (power), Plating, Galvanizing and Other Coatings, Crude, Product and CO2 Pipeline, Desalination - Industries:

Power Generation, Chemical Processing, Mining, Water Treatment, Primary Metals, Pulp and Paper, Oil and Gas - Standards:

API682, API610

Low flow, high head design provides smooth and stable operation outside the preferred operating region specified by ISO 13709.API 610.

High-efficiency, radial blade impeller provides better hydraulic fit for low flow applications and continuously rising performance curve.

Replaceable volute inserts are custom machined for each application to give best efficiency point fit for any given set of hydraulics.

Raised Face Flanges are to ASME B16.5 criteria for Class 300 or 600. Surface finish meets API 610 standard. ISO and JIS flanges are available.

ISO 21049/API 682 seal chamber accommodates multiple seal types.

Fully interchangeable with HPX bearing assembly and mechanical seals.

Operating Parameters

- Flows to 30 m3/h (130 gpm)

- Heads to 280 m (920 ft)

- Pressures to 80 bar (1160 psi)

- Temperatures from -160°C (-250°F) to 450°C (840°F)

HPXM Centrifugal Pumps User Instructions

Installation, Operation, and Maintenance for Single stage, single suction, radially split volute type centrifugal pumps

HPX Pump Bulletin

Flowserve HPX Pump – Hydrocarbon Processing Pump – ISO 13709/API 610 (OH2)

HPXM Pump Bulletin

Flowserve HPXM Pumps – ISO 13709/API 610 (OH2), Centerline Mounted, Low-Flow, High-Head, Overhung Process Pump

CPXR Recessed Impeller ISO Chemical Process Pump

CPXR Recessed Impeller ISO Chemical Process Pump

| Brand: | IDP |

|---|---|

| Description: | The Durco CPXR Recessed Impeller pump provides low-shear pumping of friable solids and trouble-free pumping of stringy or… |

The Durco CPXR Recessed Impeller pump provides low-shear pumping of friable solids and trouble-free pumping of stringy or fibrous slurries. Solids are drawn into the vortex of swirling liquid and discharged by centrifugal force through the open area in front of the impeller with little contact.

- Applications:

Waste Treatment, Water Treatment, Auxiliary Services (power), Chemical and Liquor (pulp and paper), Food Processing, Acid Transfer, Auxiliary (chemical), Caustic and Chlor-alkali, Pharmaceuticals, Polymers, Slurry Processing, Slurry Transfer (mining), Solvents, Volatile Organic Compounds, Waste Processing, Water Supply and Distribution (water), Agriculture - Industries:

Water Resources, Chemical Processing, Pulp and Paper, Mining, Power Generation, General Industries - Standards:

ISO

Vortex Action allows only a fraction of the media to contact the impeller, minimizing abrasive wear and maintaining solids integrity.

Advanced 45° Conical Seal Chamber with integral vortex flow modifiers increases mechanical seal life.

Standard Non-Contacting Labyrinth Seals keep lubricant in and contaminants out.

Heavy-Duty Pump End and Drive End Bearings selected for long life and reliability.

Operating Parameters

- Flows to 750 m3/h (3300 gpm)

- Heads to 100 m (330 ft)

- Pressures to 25 bar (365 psi)

- Temperatures from -80C (-110F) to 350C (660F)

CPX Pump Bulletin

Flowserve CPX Pumps – ISO Chemical Process Pumps – CPX, CPXS, CPXM, CPXP, CPXR, CPXV

CPX, CPXR, CPXN and CPXP Pump User Instructions

Installation, Operation, and Maintenance Instructions for Single stage, end suction, centrifugal, chemical process pumps (Based on C937KH013, C937KH054, C961KH001 and C937KH067)

CPXM ISO Overhung, Close Coupled, Process Pump

CPXM ISO Overhung, Close Coupled, Process Pump

| Brand: | IDP |

|---|---|

| Description: | Offering state-of-the-art hydraulics and a compact, space saving arrangement, the CPXM pump is designed for applications… |

Offering state-of-the-art hydraulics and a compact, space saving arrangement, the CPXM pump is designed for applications where high performance, superior efficiency and low NPSH are required. Conforms to ISO 2858 dimensional and technical standards and to ISO 5199 design criteria.

- Applications:

General Processing Industry, Caustic and Chlor-alkali, Chemical Processing, Aquariums, Acid Transfer, Water Treatment, Solvents, Waste Processing, Polymers, Organic Chemicals, Light Slurries, Petrochemical Processing - Industries:

Acid Transfer, HVACI, Agriculture, OEM, Automotive and Aircraft, Pharmaceuticals, Auxiliary, Plating, Galvanizing and Other Coatings, Bleach Chemicals, Polymers, Boiler Feed, Slurry Processing, Caustic and Chlor-Alkali, Solvents, Chemical and Liquor, Volatile Organic Compounds, Coatings, Waste Processing, Construction, Cooling Water – Metals, Dewatering & Water Supply, Electronics, Fire Protection – General Industry, Water Supply and Distribution, Food Processing, Water Treatment, Hydraulic Press - Standards:

ISO

CPXM and CPXRM Centrifugal Pumps User Instructions

Installation, Operation, and Maintenance Instructions for Close coupled, single stage, end suction, centrifugal, chemical process pumps (Based on C939KH038, and C937KH050)

MEN Overhung, End Suction Industrial Process Pump

MEN Overhung, End Suction Industrial Process Pump

| Brand: | IDP |

|---|---|

| Description: | The rugged and reliable MEN end suction water pump is the preferred choice for general purpose water applications. Versatile… |

The rugged and reliable MEN end suction water pump is the preferred choice for general purpose water applications. Versatile and dependable, the MEN offers interchangeable parts among a wide variety of pump sizes and configurations.

- Applications:

Fire Protection, Agriculture, Water Supply and Distribution (water), Water Treatment, Ground Water Development and Irrigation, HVAC - Industries:

Water Resources, General Industries

Volute Casing Design has raised face flanges to ISO PN 10/16 or ANSI B16.1 specifications.

Precision Cast Closed Impeller with extended hub has machined shrouds and is dynamically balanced for high efficiency. Axial thrust is minimized by balancing chamber and holes on the rear side.

Sturdy Bearing housing incorporates large diameter, greased-for-life, reinforced ball bearings protected by thrower and covers.

Operating Parameters

•Flows to 800 m3/h (3520 gpm)

•Heads to 140 m (450 ft)

•Pressures to 16 bar (230 psi)

•Temperatures to 120°C (250°F)

MEN Stainless Steel Pump Flier

MEN Stainless Steel Pump Flier

MEN End-Suction Water Pump Bulletin

Flowserve MEN End-Suction Water Pump – MEN – MENBLOC

MEN and MENBLOC Pumps Bulletin

Flowserve MEN and MENBLOC Pumps – End-Suction Water Pumps

MEN / MHP, MEN-TI Centrifugal Pumps User Instructions Installation Operation Maintenance

Flowserve MEN/MHP, MEN-TI (Sealed for life bearings) and ME-TI (and other pumps) Centrifugal Pumps – User Instructions: Installation, Operation, Maintenance

MEN-SP centrifugal pump User Instructions

Installation, Operation, and Maintenance instructions for Single stage, vertical suspended pump, axial suction, lateral discharge type centrifugal pump.

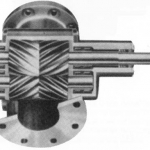

Hydrex Double Helical, Rotary Gear Pump

Hydrex Double Helical, Rotary Gear Pump

| Brand: | IDP, Worthington |

|---|---|

| Description: | The Flowserve Hydrex herringbone gear, rotary pump is a simplified but extremely reliable design for a wide variety of pumping… |

The Flowserve Hydrex herringbone gear, rotary pump is a simplified but extremely reliable design for a wide variety of pumping applications. The high pressure angle and long involute profile of the precision made herringbone gear rotors eliminate root trapping, ensure smooth power transmission, and deliver quiet, efficient operation.

- Applications:

Chemical Processing, General Purpose, Greases and Fats, High Viscosity Polymers, Marine, Pulp and Paper, Petroleum Production and Refining, Syrups, Utility

Double Helical Herringbone Gears provide quiet, pulse-free flow with better load carrying ability, greater strength and minimum hydraulic shock.

Between Bearing Design virtually eliminates shaft deflection, even while accommodating heavy, highly viscous loads.

Heavy-Duty Caged Roller Bearings result in long life. Hydrex pumps use the heaviest duty commercially available bearings.

Features:

- Direct coupled

- Single mechanical seal

- Choice of materials

- Cast iron

- Steel

- Bronze

- Stainless steel

- Optional vertical submerged tank design

- Operating parameters

- Flows to 110 m3/h (500 gpm)

- Pressures to 24 bar (350 psi)

- Temperatures from -50°C (-60°F) to 200°C (400°F)

- Viscosities from 32 to 500 000 ssu

ERPN-M Overhung, Magnetic Drive Process Pump

ERPN-M Overhung, Magnetic Drive Process Pump

| Brand: | Worthington, IDP |

|---|---|

| Description: | The ERPN-M sealless process pump is the solution for applications where leak-free pumping of hazardous, toxic, explosive… |

The ERPN-M sealless process pump is the solution for applications where leak-free pumping of hazardous, toxic, explosive or valuable liquids is required.

- Applications:

Polymers, Waste Processing, Emissions Reduction, Difficult-to-Seal Liquids, Solvents, Caustic and Chlor-alkali, Organic Chemicals, Valuable Liquids, Toxic Services, Acid Transfer - Industries:

Acid Transfer, Auxiliary

Meets API 610 Standards for the most critical parameters, including vibration limits, nozzle loading capabilities, and balancing grades.

Dynamically Balanced, High Efficiency Semi-Open Impeller limits vibration and assures smooth operation over a wide range of flow rates.

Pump Casing and Cover feature metal-to-metal fit with fully confined, controlled compression gasket to ensure proper sealing and alignment.

Features:

- Centerline supported casing

- Temperature probe

- Pressure switch

- Optional inducer

- Optional secondary containment

- Choice of API material combinations

- S-5 Carbon steel with carbon steel internals

- S-6 Carbon steel with 12% chrome internals

- S-8 Carbon steel with 316 SS internals

- C-6 12% chrome with 12% chrome internals

- A-8 316 SS with 316 SS internals

- D-1 Duplex with duplex internals

- Operating parameters

- Flows to 1100 m3/h (4800 gpm)

- Heads to 230 m (750 ft)

- Working pressures to 60 bar (870 psi)

- Suction pressures to 50 bar (725 psi)

- Temperatures to 350°C (660°F)

ERPN Pump Bulletin

Flowserve ERPN Pumps – Overhung, End-Suction Process Pump – ISO 13709/API 610 (OH2)

ERPN-M centrifugal pumps User Instructions

Installation, Operation, & Maintenance Instructions for Horizontal, End Suction Magnetic Driven Pumps

CPXS Magnetic Drive, Overhung, Chemical Process Pump

CPXS Magnetic Drive, Overhung, Chemical Process Pump

| Brand: | IDP |

|---|---|

| Description: | The CPXS Magnetic Drive pump provides leak-free pumping of hazardous, toxic, flammable, explosive or valuable liquids. Conforming… |

The CPXS Magnetic Drive pump provides leak-free pumping of hazardous, toxic, flammable, explosive or valuable liquids. Conforming to ISO 2858 dimensional and ISO 15783 design criteria, the CPXS Magnetic Drive pump is found wherever reliability in severe services is a requirement.

- Applications:

Solvents, Polymers, Water Treatment, Water Supply and Treatment (oil and gas), Acid Transfer, Construction, Caustic and Chlor-alkali - Industries:

Chemical Processing, Water Resources, Oil and Gas, General Industries - Standards:

ISO

High-Performance Rare Earth Magnets possess superior permanent strength and proven reliability.

Large Inner Magnet Clearances of 1.5 mm (0.06 in) between shell and inner magnet assembly ensure effective cooling.

Reinforced PEEK Primary Containment Shell eliminates eddy current losses, enhancing efficiency. Hastelloy® primary containment shell available.

Heavy-duty Casing with integral foot and multi-ribbed discharge flange provides outstanding resistance to pipe loads.

Semi-open Impeller delivers high-efficiency performance and provides low NPSHR.

Operating Parameters

- Flows to 420 m3/h (1850 gpm)

- Heads to 160 m (525 ft)

- Pressures to 25 bar (365 psi)

- Temperatures from -40°C (-40°F) to 250°C (480°F)

CPXS, CPXNS and CPXPS User Instructions

Installation, Operation, and Maintenance instructions for Frame mounted, modular design, centrifugal, chemical process pumps with magnetic drive. (Based on C957KH025 and C957KH049.)

CPXP Self-Priming ISO Chemical Process Pump

CPXP Self-Priming ISO Chemical Process Pump

| Brand: | IDP |

|---|---|

| Description: | Operating on the reflux priming principle, the CPXP self-priming pump offers state-of-the-art hydraulics, versatile operation… |

Operating on the reflux priming principle, the CPXP self-priming pump offers state-of-the-art hydraulics, versatile operation and reliable performance while costing considerably less to buy, install and maintain than submersible pumps.

- Applications:

Tank Car Unloading, Waste Water, Dewatering, Marine, Effluent, Sump Service - Industries:

Pharmaceuticals, Acid Transfer, Automotive and Aircraft, Auxiliary, Caustic and Chlor-Alkali, Volatile Organic Compounds, Waste Processing, Polymers, Slurry Processing, Solvents, OEM - Standards:

ISO

CPXV and CPXRV User Instructions

Installation, Operation, & Maintenance Instructions for Centrifugal, modular design, vertical sump pumps (Based on C942KH001, C942KH021 and C942KH017 User Instructions)

CPX Pump Bulletin

WXB-B Low-Flow, High-Head, Process Barrel Pump

WXB-B Low-Flow, High-Head, Process Barrel Pump

| Brand: | IDP |

|---|---|

| Description: | An extension of the well-proven WXB, the WXB-B is an API 610-style, multistage barrel pump which incorporates Barske style… |

An extension of the well-proven WXB, the WXB-B is an API 610-style, multistage barrel pump which incorporates Barske style impellers to produce stable low-flow performance. It is a reliable, direct drive solution for low-flow, high-head applications.

- Applications:

Auxiliary (chemical), Catalytic Cracking, Crude, Product and CO2 Pipeline, FPSO, Gas to Liquids, Water and CO2 Injection, Hydrocracking, Hydrotreating, LNG, Residuum and Heavy Oil Upgrading, Heavy Oil, Oil Sands and Shale - Industries:

Oil and Gas, Chemical Processing

Barske Style Impeller provides a continuously rising performance curve with exceptional low-flow stability.

Diffuser Style, Inner Case Subassembly allows for balanced radial loads and produces a compact design.

Standard Casing Wear Rings permit economical restoration of running clearances.

Barrel Casing is centerline mounted to permit symmetrical thermal expansion without loss of alignment.

Nozzles are engineered to meet the ISO 13709/API 610 loads as standard.

ISO 21049/API 682 Seal Chamber accommodates numerous types of mechanical seals.

Operating Parameters

- Flows from 2.5 m3/h (11 gpm) to 29 m3/h (128 gpm)

- Heads to 1560 m (5116 ft)

- Pressures to 200 bar (2900 psi)

- Temperatures to 200°C (392°F)

- Speeds to 3600 rpm

WXB-B Pumps Bulletin

Flowserve WXB-B Pumps – Low-Flow, High-Head Barrel Pump for Refinery and Petrochemical Industries

WM2 API 610 (OH5), Overhung, Close Coupled, Vertical In-Line, Low Flow, Two Stage Pump

WM2 API 610 (OH5), Overhung, Close Coupled, Vertical In-Line, Low Flow, Two Stage Pump

| Brand: | IDP |

|---|---|

| Description: | The Flowserve WM2 is the space-saving, close coupled configuration of the HWM2 pump. This two-stage pump is designed specifically… |

The Flowserve WM2 is the space-saving, close coupled configuration of the HWM2 pump. This two-stage pump is designed specifically for low flow, medium to high head operation and is fully compliant with API 610 (OH5), latest edition.

- Applications:

Boiler Circulation, Gas Industry Service , General Purpose, Water, Petrochemical Processing, Petroleum Distribution, High Temperature Service - Industries:

Utilities, SAGD, NGL, Logistics and Tank Farm, LNG, Hydrotreating, Hydrocraking, Gas Treatment, Gas-to-Liquids, Distillation, Crude Handling and Treatment, Catalytic Cracking, Water Handling and Treatment - Standards:

API610

Low Flow, High Head Design for smooth, stable operation outside the preferred operating region specified by API 610.

Modular Design provides more than 100 BEP fits in one pump size.

Replaceable Volute Inserts to handle changing operating conditions.

Radial Blade Impeller provides a continuously rising performance curve with low flow stability. Impeller is dynamically balanced to limit vibration and ensure smooth operation over wide flow range.

Close Coupled Design to latest edition of API 610.

API 682 Seal Chamber accommodates a wide variety of seal configurations including dual pressurized and unpressurized cartridge types for the most severe services.

Features:

- Optional inducer for low NPSH requirements

- Other configurations

- WM (low flow, high head, single stage)

- Operating parameters

- Flows to 30 m3/h (130 gpm)

- Heads to 440 m (1450 ft)

- Pressures to 60 bar (850 psi)

- Temperatures from -45°C (-50°F) to 260°C (500°F)

HWM, HWM2, WM, and WM2 Pumps Bulletin

Flowserve HWM, HWM2, WM, and WM2 Pumps – HWM, HWM2 – ISO 13709/API 610 (OH3) Pump Bearing Frame WM, WM2 ISO 13709/API 610 (OH5) Close Coupled – Vertical In-Line, One- and Two-Stage, Low-Flow, High-Head Process Pumps

WM API 610 (OH5), Overhung, Close Coupled, Vertical In-Line, Low Flow Pump

WM API 610 (OH5), Overhung, Close Coupled, Vertical In-Line, Low Flow Pump

| Brand: | IDP |

|---|---|

| Description: | The Flowserve WM pump is the space-saving, close coupled configuration of the HWM pump. This pump is designed specifically… |

The Flowserve WM pump is the space-saving, close coupled configuration of the HWM pump. This pump is designed specifically for low flow, high head operation and is fully compliant with API 610 (OH5), latest edition.

- Applications:

Petrochemical Processing, Petroleum Distribution, Water, High Temperature Service, Gas Industry Service , General Purpose, Boiler Circulation - Industries:

Delayed Coking, Catalytic Cracking, Crude Handling and Treatment, Water Handling and Treatment, Utilities, SAGD, Distillation, Logistics and Tank Farm, LNG, Hydrotreating, Hydrocraking, Gas Treatment, Gas-to-Liquids, NGL - Standards:

API610

Modular Design provides more than 100 BEP fits in one pump size.

Replaceable Volute Inserts to handle changing operating conditions.

Radial Blade Impeller provides a continuously rising performance curve with low flow stability. Impeller is dynamically balanced to limit vibration and ensure smooth operation over wide flow range.

Close Coupled Design to latest edition of API 610.

API 682 Seal Chamber accommodates a wide variety of seal configurations including dual pressurized and unpressurized cartridge types for the most severe services.

Features:

- Optional inducer for low NPSH requirements

- Other configurations

- WM2 (low flow, high head, 2-stage)

- Operating parameters

- Flows to 30 m3/h (130 gpm)

- Heads to 220 m (725 ft)

- Pressures to 50 bar (750 psi)

- Temperatures from -45°C (-50°F) to 260°C (500°F)

HWM, HWM2, WM, and WM2 Pumps Bulletin

Flowserve HWM, HWM2, WM, and WM2 Pumps – HWM, HWM2 – ISO 13709/API 610 (OH3) Pump Bearing Frame WM, WM2 ISO 13709/API 610 (OH5) Close Coupled – Vertical In-Line, One- and Two-Stage, Low-Flow, High-Head Process Pumps

WDF Nuclear Vertical, Single Stage Pump

WDF Nuclear Vertical, Single Stage Pump

| Brand: | IDP |

|---|---|

| Description: | The WDF is a vertical, single stage pump specifically designed for safety related shutdown services in nuclear power plants.… |

The WDF is a vertical, single stage pump specifically designed for safety related shutdown services in nuclear power plants. It features bottom suction and side discharge for a compact piping arrangement.

- Applications:

Nuclear Service - Industries:

Power Generation - Standards:

Nuclear, ASME (ANSI)

Bottom Suction And Side Discharge Nozzles provide for compact piping arrangement.

Three-Piece Spacer Coupling allows for maintenance to the seal without needing to remove the motor.

Cartridge Seal provides ease of maintenance.

Enclosed Impeller allows for equal thermal growth in case the pump is shocked with high temperature water.

Separate Bearing Support above the seal chamber provides shaft support and reduces vibration input to the mechanical seal.

Operating Parameters

- Flows to 900 m3/h (4000 gpm)

- Heads to 245 m (800 ft)

Nuclear Power Pumps

Flowserve Pumps for Nuclear Power – Pumps – Seals – Engineering and Technical Support – Re-rates and Upgrades – Aftermarket Services

WD-WDF Vertical, Single-Stage Nuclear RHR Pump Bulletin

Flowserve WD-WDF Vertical, Single-Stage Nuclear RHR Pump – ASME Section III, Class 2 and 3

W API 610 (OH4), Radially Split, Vertical In-Line, Rigid Coupled, Process Pump

W API 610 (OH4), Radially Split, Vertical In-Line, Rigid Coupled, Process Pump

| Brand: | Wilson-Snyder, Worthington, Pacific, Byron Jackson, IDP, United Centrifugal |

|---|---|

| Description: | The Type W is a radially split, single stage, single suction, vertical in-line pump and is compliant with API 610 (OH4),… |

The Type W is a radially split, single stage, single suction, vertical in-line pump and is compliant with API 610 (OH4), latest edition. It is designed for continuous duty service on all process and industrial applications.

- Applications:

Booster, Desalination, Offsites, Process - Industries:

NGL, SAGD, Utilities, Water Handling and Treatment, Catalytic Cracking, Crude Handling and Treatment, Logistics and Tank Farm, Distillation, Gas-to-Liquids, Gas Treatment, Hydrocraking, Hydrotreating, LNG, Delayed Coking

Heavy-Duty Casing supports pump and motor when mounted in line. Dual volute design on larger discharge pumps minimizes radial thrust, reduces shaft deflection, and increases seal life.

Dynamically Balanced Impeller is precision cast and positively locked against rotation.

Generous Seal Cavity accommodates single, double and tandem seals.

Shaft run-out can be set on installed unit with adjustable, rigid spacer coupling, maximizing seal life.

Motor Support designed to allow back pull-out for ease of maintenance or inspection. Precision machined rabbet fit provides positive alignment between pump and motor.

Features:

- Choice of API material classes

- S-1 Carbon steel with cast iron internals

- S-6 Carbon steel with 12% chrome internals

- D-1 Duplex with duplex internals

- C-6 12% chrome with 12% chrome internals

- S-N 316 SS with Nitronic® internals

- A-8 316 SS with 316 SS internals

- Operating parameters

- Flows to 1500 m3/h (6600 gpm)

- Heads to 300 m (1000 ft)

- Pressures to 80 bar (1160 psi)

- Temperatures to 400°C (750°F)

®Nitronic is a registered trademark of AK Steel

HWX API 610 Vertical In-Line Process Pumps Bulletin

Flowserve HWX API 610 Vertical In-Line Process Pumps – API OH3 Pump Bearing Frame, API OH4 Rigidly Coupled, API OH5 Close Coupled

SMX Non-Metallic Standard Motor Overhung Industrial Process Pump

SMX Non-Metallic Standard Motor Overhung Industrial Process Pump

| Brand: | IDP |

|---|---|

| Description: | The SMX non-metallic motor pump is an overhung, end suction, close coupled tangential discharge, frame mounted design, engineered… |

The SMX non-metallic motor pump is an overhung, end suction, close coupled tangential discharge, frame mounted design, engineered for general industry use.

- Applications:

Water Treatment, HVAC, Water Supply and Distribution (water), Auxiliary (chemical), OEM - Industries:

Chemical Processing, Water Resources, General Industries

Non-Metallic Casing, Adapter and Impeller made of polyphenylene sulfide (PPS) are corrosion resistant and offer a cost advantage over metallic pumps in many applications.

Self-Aligning Mechanical Seal with Buna gasketing, carbon vs. stainless steel seal faces, and 18-8 stainless steel components, requires no adjustment.

Standard NEMA 56J Frame C-Faced Motor offers maximum flexibility, interchangeability and versatility.

Sealed for Life Prelubricated Motor Bearings provide two-year minimum life.

One and One-Half Inch Ports enable convenient hose connection.

Features:

- Back pullout design

Operating Parameters

- Flows to 25 m3/h (100 gpm)

- Heads to 20 m (60 ft)

- Pressures to 12 bar (175 psi)

- Temperatures to 80°C (180°F)

SMP Series Standard Motor Pumps Bulletin

Flowserve SMP Series Standard Motor Pumps – SMP, SMX, VSMP

SMP Standard Motor Pump Bulletin

Flowserve SMP Standard Motor Pumps – SMP, SMX, and VSMP

SMP Standard Motor Overhung Industrial Process Pump

SMP Standard Motor Overhung Industrial Process Pump

| Brand: | IDP |

|---|---|

| Description: | The SMP standard motor pump is an overhung, end suction, close coupled, tangential discharge, frame mounted design, engineered… |

The SMP standard motor pump is an overhung, end suction, close coupled, tangential discharge, frame mounted design, engineered for general industry use.

- Applications:

Water Treatment, HVAC, Auxiliary (chemical), Water Supply and Distribution (water), OEM - Industries:

Chemical Processing, Water Resources, General Industries

High-Efficiency Semi-Open or Closed Impellers in standard glass reinforced polymer or optional cast iron, bronze or 316 SS to suit service conditions. Impellers are keyed to shaft for positive drive and maximum efficiency.

Industry Standard NEMA Motors result in maximum flexibility, interchangeability and versatility.

Self-Aligned Mechanical Seal, with stainless steel parts, is positioned by the impeller, keeping pumped fluid away from the motor and minimizing leakage.

Back Pullout Design facilitates routine inspection and maintenance.

Operating Parameters:

- Flows to 135 m3/h (600 gpm)

- Heads to 70 m (220 ft)

- Pressures to 12 bar (175 psi)

- Temperatures from -40°C (-40°F) to 120°C (250°F)

SMP Series Standard Motor Pumps Bulletin

Flowserve SMP Series Standard Motor Pumps – SMP, SMX, VSMP

SMP Standard Motor Pump Bulletin

Flowserve SMP Standard Motor Pumps – SMP, SMX, and VSMP

MSX Overhung, Solids Handling, Submersible Pump

MSX Overhung, Solids Handling, Submersible Pump

| Brand: | IDP |

|---|---|

| Description: | The Flowserve MSX family of solids handling, submersible pumps is engineered to perform efficiently in the most challenging… |

The Flowserve MSX family of solids handling, submersible pumps is engineered to perform efficiently in the most challenging environments, from pumping raw sewage to moving industrial wastewater and solids-laden liquids.

- Applications:

Water Treatment, Flood Control, Auxiliary Services (power), Chemical and Liquor (pulp and paper), Waste Processing, Ground Water Development and Irrigation, Offsites and Waste Treatment, Sewage Collection and Treatment, Dewatering and Water Supply (mining) - Industries:

Chemical Processing, Mining, Water Resources, Power Generation, Pulp and Paper, Oil and Gas

High-Efficiency Hydraulics reduce energy consumption and operating costs while providing constant, predictable pumping performance.

EPACT-Rated Motor offers high-efficiency performance for impressive energy savings.

Spike-Resistant Windings provide smooth, consistent motor performance and the ability to handle voltage spikes with variable frequency drive motor option.

Class H Insulation System significantly extends motor life.

Shaft and Rotor are dynamically balanced for reduced vibration to ensure smooth operation and long service life.

Features:

- MSX-Series 1

- Solids handling to 80 mm (3 in) spherical

- Watertight cable entry

- Long-life, angular contact bearings

- Environmentally friendly sealing fluid

- Sizes to 150 mm (6 in)

- MSX-Series 2/3

- Solids handling to 80 mm (3 in) spherical

- Easy access terminal chamber

- Closed-loop cooling design

- Heat exchanger for additional motor cooling

- Long-life, tapered roller bearings

- Sizes to 500 mm (20 in)

- Mounting options

- Wet-pit

- Dry-pit

- Transportable

Operating Parameters

- Flows to 4545 m3/h (20 000 gpm)

- Heads to 90 m (300 ft)

- Temperatures to 40°C (104°F)

- Discharge sizes from 80 mm (3 in) to 500 mm (920 in)

- Motor to 224 kW (300 hp)

- Solids handling to 80 mm (3 in) diameter spherical

HWMA2 ISO 13709/API 610 (OH3) Vertical In-line, Low-Flow, High-Head Overhung API Process Pump

HWMA2 ISO 13709/API 610 (OH3) Vertical In-line, Low-Flow, High-Head Overhung API Process Pump

| Brand: | IDP |

|---|---|

| Description: | Flowserve’s HWMA is a two stage, vertical in-line overhung pump with a separate bearing bracket. With its small footprint,… |

Flowserve’s HWMA is a two stage, vertical in-line overhung pump with a separate bearing bracket. With its small footprint, this low flow, high head process pump is a space-saving alternative to many overhung process pumps in upstream and downstream services.

- Applications:

Heat Transfer Fluids, Gas to Liquids, Acid Transfer, Hydrocracking, Boiler Feed Booster, Hydrotreating, Catalytic Cracking, Industrial Gases, Caustic and Chlor-alkali, LNG, Chemical and Liquor (pulp and paper), Leaching Acid, Cooling Water (power), Crude, Product and CO2 Pipeline, Plating, Galvanizing and Other Coatings, Desalination, Residuum and Heavy Oil Upgrading, Digester, Solvents, Distillation (oil and gas), Volatile Organic Compounds, Drilling and Production, Water Supply and Treatment (oil and gas), FPSO, Water and CO2 Injection, Gas Treating and Sulfur Recovery, Heavy Oil, Oil Sands and Shale - Industries:

Chemical Processing, General Industries, Water Resources, Power Generation, Oil and Gas - Standards:

API682, API610

Replaceable Volute Insert permits precise hydraulic customization. Each insert is engineered for specified head and flow requirements. Accommodates future system changes.

Casing and Cover feature metal-to-metal fits with fully confined, controlled compression gasket to ensure proper sealing and alignment.

Raised Face Flanges are to ASME B16.5, Class 300 for one stage and Class 600 for two stage models.

ISO 21049/API 682 Seal Chamber accommodates a wide variety of seal configurations including dual pressurized and unpressurized cartridge types for the most severe services.

Stiff Shaft Design limits deflection at seal faces to 0.05 mm (0.002 in) max. Vibration levels are well below that required by ISO 13709/API 610. (insert period)

Heavy-Duty Motor Support Head features a registered fit motor mount and does not use spacer plates.

Operating Parameters

- Flows to 45 m3/h (200 gpm)

- Heads to 440 m (1455 ft)

- Pressures to 60 bar (870 psi)

- Temperatures to 260°C (500°F)

HWMA Pump Bulletin

Flowserve HWMA Pumps – Low-Flow, High-Head, Vertical In-line Process Pump With Bearing Housing – ISO 13709/API 610 (OH3) – HWMA2, WMA and WMA2 models included.

ESP3 Chemical Vertical Sump Pump

ESP3 Chemical Vertical Sump Pump

| Brand: | IDP |

|---|---|

| Description: | Boasting the same casing, reverse vane impeller and CBL cover as the industry-leading Durco Mark 3 chemical process pump,… |

Boasting the same casing, reverse vane impeller and CBL cover as the industry-leading Durco Mark 3 chemical process pump, the ESP3 is the only vertical wet-pit immersion sump pump to offer parts interchangeable with standard ASME B73.1 horizontal pumps.

- Applications:

Agriculture, Automotive, Auxiliary (chemical), Auxiliary Services (power), Caustic and Chlor-alkali, Electronics, Food Processing, HVAC, OEM, Pharmaceuticals, Polymers, Renewable Fuel Production, Sewage Collection and Treatment, Shipping, Slurry Processing, Solvents, Acid Transfer, Water Supply and Treatment (oil and gas), Water Treatment - Industries:

Chemical Processing, Oil and Gas, Water Resources, General Industries, Power Generation

ANSI Standard Casing Design is offered in a wide range of materials, including abrasion resistant high chrome iron, to suit application requirements.

Standard Reverse Vane Impeller offers repeatable performance throughout the life of the pump. Open impellers available for stringy or fibrous liquids.

T.B. Woods Sure-Flex® Couplings are precision machined and self-aligning.

Large Polypropylene Basket Strainer resists corrosion.

Factory Flanged Discharge simplifies field piping and is available in a variety of configurations.

Available Low-Flow and Recessed Impeller configurations.

Operating Parameters

- Flows to 1300 m3/h (5700 gpm)

- Heads to 92 m (300 ft)

- Pressures to 12 bar (175 psi)

- Temperatures to 180°C (350°F)

- Pit depths to 6 m (20 ft); greater depths achievable with optional tailpipe

ESP3 Vertical Immersion Sump Pump User Instructions

ESP3 Vertical Immersion Sump Pump User Instructions

EG Nuclear Radially Split, Double Suction Pump

EG Nuclear Radially Split, Double Suction Pump

| Brand: | IDP |

|---|---|

| Description: | The EG is a single stage, double suction, radial split case, heavy duty process pump, specifically designed for component… |

The EG is a single stage, double suction, radial split case, heavy duty process pump, specifically designed for component cooling water service for the AREVA nuclear plants. Conforming to ASME Section III, Class 3, it features centerline mounting and suction with discharge flange in the top portion of the pump casing.

- Applications:

Nuclear Service - Industries:

Power Generation

Suction and Discharge connections in the top portion of the pump case meet AREVA piping requirements. They are designed to exceed double the API requirements, per AREVA pipe loading specifications.

Radially Split Casing allows for maintenance of the pump internals without having to disconnect the suction and discharge piping.

Double Suction Impeller reduces NPSR over the operating range of the pump.

Centerline Mounted Design allows for equal thermal expansion.

360-degree bearing brackets provide optimal support for the bearing housing.

Standard Cartridge Seals simplify maintenance.

Operating Parameters

- Flows to 4000 m3/h (17 610 gpm)

- Heads to 60 m (200 ft)

- Pressures to 14 bar (200 psi)

- Temperatures to 80°C (180°F)

- Power to 950 kW (1275 hp)

- Speeds to 3600 rpm

Nuclear Power Pumps

Flowserve Pumps for Nuclear Power – Pumps – Seals – Engineering and Technical Support – Re-rates and Upgrades – Aftermarket Services

CSB Between Bearings, Double Case, Diffuser Casing, Multistage, Utility Barrel Pump

CSB Between Bearings, Double Case, Diffuser Casing, Multistage, Utility Barrel Pump

Brand |

Description |

| IDP | The CSB Between Bearings Double Case Diffuser Casing Multistage Utility Barrel Pump is designed to deliver superior performance and efficiency for demanding industrial applications. Engineered for durability and ease of maintenance, this pump is ideal for use in critical services, such as boiler feed and thermal power plant operations. With its advanced diffuser-style design, the CSB Pump ensures reliability and cost-effectiveness, meeting the rigorous demands of modern industries. |

Features

- Energy Efficiency: Optimized continuous crossover diffusers enhance energy savings.

- Ease of Maintenance: A radially split inner case ensures quick and easy servicing.

- Durable Construction: High-strength chromium steel forged barrel for maximum durability.

- Extended Service Life: High shaft diameter-to-bearing span ratio reduces operational wear and tear.

- Versatility: Suitable for a wide range of industrial applications, including power generation, water treatment, and chemical processing.

Operating Parameters

- Flow Rate: Up to 1,136 m³/h (5,000 gpm).

- Head: Up to 2,438 m (8,000 ft).

- Pressure: Up to 310 bar (4,500 psi).

- Temperature Range: Up to 250°C (480°F).

- Sizes Available: 3? to 10? (75 mm to 250 mm)

Applications

The CSB Between Bearings Pump is versatile and ideal for:

- Boiler Feed Systems: In combined cycle and thermal power plants.

- Chemical Processing: Efficient handling of critical fluids.

- Water Treatment: High-pressure pumping solutions.

- Oil and Gas: Designed for challenging upstream and downstream applications

CHTA BETWEEN BEARINGS DIFFUSER CASING, UTILITY BARREL PUMP

| BRAND | DESCRIPTION |

| FLOWSERVE | The Flowserve CHTA Between Bearings Diffuser Casing, with either a double suction or a single suction first-stage impeller, is a double-casing, multistage horizontal multistage double case pump. Designed as part of the IDP® CHTA Between Bearings Pump range, it ensures exceptional reliability and efficiency for critical applications requiring between bearings pumps. |

The Flowserve CHTA, with either a double suction or a single suction first stage impeller, is a double casing, multistage barrel pump. The CHTA is specifically designed and built for high temperature, high pressure and high flow applications, including boiler feedwater and water injection.

- Applications:

Boiler Feed - Industries:

Power Generation

Precision Cast Diffusers minimize bearing spans, thereby increasing pump reliability and efficiency.

Suction and Discharge Connections can be located on the top or the bottom of the barrel and may be supplied with flanged or weld end design to suit installation requirements.

Forged and Hardened Stainless Steel Balance Drum is conservatively sized to completely unload the thrust bearing at all operating points.

Self-Aligning, Double-Acting Tilt-Pad Thrust Bearings are conservatively rated to carry axial loads that may be encountered during transient operating conditions.

Precision Cast Tandem Impellers are positively locked and keyed to the shaft.

Serrated Impeller Running Fits reduce the effects of rotor contact during system upsets or turning gear operation.

Operating Parameters

- Flows to 5250 m3/h (23 000 gpm)

- Heads to 4300 m (14 000 ft)

- Discharge pressures to 450 bar (6525 psi)

- Temperatures to 250°C (480°F)

- Speeds to 6000 rpm

CSX BETWEEN BEARING PUMP

CSX BETWEEN BEARING PUMP

Brand |

Description |

| IDP | The Flowserve CSX Between Bearings Pump is a Horizontal Multistage Pump designed for high-efficiency, high-pressure membrane feed applications, especially in reverse osmosis desalination (RO) systems. This Single Case Pump is built to deliver exceptional performance in seawater and brackish water desalination, along with other industrial applications requiring reliable, energy-efficient solutions. With advanced design and corrosion-resistant materials, the CSX pump ensures long-term durability and minimized lifecycle costs, making it the ideal choice for critical applications. |

-

High-Efficiency Performance

The CSX Between Bearings Pump uses an advanced hydraulic design to minimize energy consumption while ensuring high efficiency in high-pressure applications. The precision-cast impellers and optimally designed diffusers reduce energy losses, providing better performance and lower operating costs. - Corrosion-Resistant Construction

Built with Super Duplex Stainless Steel (A890 Gr. 5A/6A), the CSX pump is highly resistant to corrosion, making it perfect for use in harsh environments like seawater desalination systems. - Precision-Cast Impellers

The impellers are dynamically balanced to G2.5 standard, ensuring smooth and stable operation throughout the pump’s lifecycle. This results in reliable performance and reduced wear on key components. - Lubrication Flexibility

The CSX pump offers two lubrication options: product-lubricated bearings for cleaner operation and oil-lubricated bearings for traditional applications, providing flexibility depending on the specific needs of the operation. - Stiff Rotor Design

The stiff rotor design reduces deflection, leading to improved bearing and seal life, which enhances overall pump reliability. - Flexible Nozzle Configuration

The nozzle heads are independently configurable in 90-degree steps, providing flexibility to meet various installation requirements.

Specifications

| Specification | Value |

|---|---|

| Flow | Up to 1500 m³/h (6600 gpm) |

| Head | Up to 840 m (2756 ft) |

| Pressure | Up to 100 bar (1450 psi) |

| Temperature | Up to 45°C (113°F) |

| Pump Type | Horizontal Multistage Pump, Single Case Pump |

| Material Options | Super Duplex Stainless Steel A890 Gr. 5A/6A |

| Lubrication Options | Product-lubricated and Oil-lubricated |

| Impeller Type | Precision-Cast Impellers (dynamically balanced to G2.5) |

| Rotor Design | Stiff Rotor to reduce deflection |

| Nozzle Configuration | Independently configurable in 90-degree steps |

The CSX Between Bearings is ideal for:

- Reverse Osmosis Desalination

The CSX Between Bearings Pump is designed for membrane feed duties in seawater reverse osmosis (SWRO) systems. Its high-efficiency design ensures excellent performance in both first-pass and second-pass desalination operations, making it ideal for continuous desalination plants. - Water Treatment Plants

In water treatment facilities, the CSX pump offers energy-efficient and reliable solutions for high-pressure membrane feed applications, ensuring stable water quality and reliable system performance. - Industrial Water Supply Systems

The CSX pump is perfect for industrial applications requiring high-capacity, high-pressure pumps to supply treated water efficiently with minimal downtime. - Oil and Gas Industry

Its corrosion-resistant materials and ability to handle high-pressure applications make the CSX pump a reliable choice for oil and gas operations requiring seawater or other process fluid pumping. - Power Generation

The CSX pump is used in power plants for cooling towers and water treatment applications, maintaining continuous water supply and optimizing plant efficiency.

CA Nuclear Pump

CA Nuclear Pump

Brand |

Description |

| IDP | The CA pump was specifically built for nuclear safety injection service. This radially split, between-bearing, multistage Flowserve CA Nuclear Pump is extremely reliable and efficient, making it an excellent choice for sensitive nuclear pump applications that require high-performance pumps. |

CA Nuclear Diffuser Casing

The CA pump is designed specifically for nuclear safety injection service. This radially split, between bearing, multistage design complies with ASME Section III< Class 2 and 3.

- Applications:

Nuclear Service - Industries:

Power Generation - Standards:

Nuclear

Precision Cast Diffusers minimize bearing spans, thereby increasing pump reliability and efficiency.

Suction and Discharge Connections can be located on the top or the bottom of the barrel and may be supplied with flanged or weld end design to suit installation requirements.

Forged and Hardened Stainless Steel Balance Drum is generously sized to completely unload the thrust bearing at all operating points.

Self-Aligning, Double-Acting Tilt-Pad Thrust Bearings are conservatively rated to carry axial loads that may be encountered during transient operating conditions.

Precision Cast Tandem Impellers are positively locked and keyed to the shaft.

Serrated Impeller Running Fits reduce the effects of rotor contact during system upsets or turning gear operation.

Flowserve CA Nuclear Pump Operating Parameters

- Flows to 5250 m3/h (23 000 gpm)

- Discharge pressures to 450 bar (6500 psi)

- Temperatures to 250°C (480°F)

- Speeds to 6000 rpm

APKD Vertical, Double Case, Double Suction Pump

APKD Vertical, Double Case, Double Suction Pump

| Brand: | IDP |

|---|---|

| Description: | The double case APKD features an innovative, double suction impeller in a true twin-volute design that produces more flow… |

The double case APKD features an innovative, double suction impeller in a true twin-volute design that produces more flow and higher head at lower NPSHR and can operate at higher speeds than conventional vertical turbine pump models.

- Applications:

Nuclear Service, Crude, Product and CO2 Pipeline, Cooling Water (power), Condensate Extraction - Industries:

Oil and Gas, Power Generation

Broad Hydraulic Versatility through a series of impeller design options enables better hydraulic fit for each application. The result is lower energy consumption and operating costs.

Double Suction First Stage Impeller reduces NPSHR and meets Hydraulic Institute standards for suction-specific speed. This design means a shorter, more rigid pump, providing freedom from cavitation over a wide operating range.

Double Volute Design minimizes radial loads, extending bearing life.

Suction Can creates optimal hydraulic conditions through the suction flange inlet into the suction bell.

Rigid, Adjustable Flanged Coupling maintains accurate pump-motor alignment, provides proper impeller clearance adjustment and facilitates seal maintenance.

Operating Parameters

- Flows to 4600 m3/h (20 200 gpm)

- Heads to 500 m (1640 ft)

- Pressures to 50 bar (725 psi)

- Temperatures from -45°C (-50°F) to 95°C (200°F)

- Speeds to 1800 rpm

CN Radially Split, Diffuser Casing, Single-Stage Nuclear Pump

CN Radially Split, Diffuser Casing, Single-Stage Nuclear Pump

| Brand: | IDP |

|---|---|

| Description: | The CN single-stage, high-speed pump features a rugged, diffuser-style barrel design. Designed to ASME Section IV Division… |

The CN single-stage, high-speed pump features a rugged, diffuser-style barrel design. Designed to ASME Section IV Division 1 requirements as well as customer specifications, it also features a centerline mounted, radially split casing and a double-suction impeller. This design renders nearly balanced axial hydraulic thrust over the full operating range of the pumps.

- Applications:

Nuclear Service - Industries:

Power Generation

416 Stainless Steel Shaft is ground in steps to minimize stresses. It is then stress relieved in the vertical position to prevent warping.

Precision Cast Chrome Steel Impellers are secured to the shaft with keys and a shrink fit against a shaft shoulder.

Serrated Impeller Running Fits reduce the effects of rotor contact during system upsets or turning gear operation.

Suction and Discharge Nozzles can be provided in numerous configurations to accommodate plant piping layouts.

Robust Bearing System uses split sleeve tri-land hydrodynamic radial bearings to support radial loads. Axial loads are carried by pivot shoe thrust bearings.

Full 360-degree bearing housings are used (omitted: “on the CN pump”) for added rigidity.

Advanced Sealing System is a controlled leakage design that employs a fixed serrated bushing over a straight shaft sleeve at each end of the pump.

Operating Parameters

- Flows to 5065 m3/h (22 300 gpm)

- Heads to 800 m (2625 ft)

- Pressures to 100 bar (1470 psi)

- Temperatures to 210°C (410°F)

Nuclear Power Pumps