Flowserve

The result of years of research, thousands of hours of rigorous testing and decades of primary pump application experience, the Flowserve N-Seal primary pump seal represents the nuclear industry’s most advanced mechanical seal technology. With each of three stages capable of sustaining 100% system pressure, the N-Seal has successfully provided proven service life and fail-safe redundancy in Flowserve Byron Jackson® primary coolant pumps for years.

N-Seal Nuclear Primary Pump Seal

N-Seal Nuclear Primary Pump Seal

| Brand: | Flowserve |

|---|---|

| Description: | The result of years of research, thousands of hours of rigorous testing and decades of primary pump application experience,… |

The result of years of research, thousands of hours of rigorous testing and decades of primary pump application experience, the Flowserve N-Seal primary pump seal represents the nuclear industry’s most advanced mechanical seal technology. With each of three stages capable of sustaining 100% system pressure, the N-Seal has successfully provided proven service life and fail-safe redundancy in Flowserve Byron Jackson® primary coolant pumps for years.

- Applications:

Nuclear Service - Industries:

Power Generation

N-Seal Interactive Animation

This self-paced, interactive tool features a highly detailed 3-D model of the N-Seal primary pump seal. Users will learn about the anatomy of the seal, its important design features, and its many safety and reliability benefits.

Unique Cartridge Construction simplifies installation, enables more accurate seal setting, and keeps associated costs low.

Triple Redundant Seal Design mirrors existing seal system parameters. Each of the three stages can handle 100% of the system pressure.

Hydrodynamic Seal Face Technology outperforms hydrostatic designs with dramatically improved reliability and running periods.

Three different seal face lift designs are available to ensure non-contacting faces over a broad operating range.

Pressure is Automatically Redistributed to the remaining two stages in the event of a stage failure, allowing the plant to complete the fuel cycle.

Interchangeability of Stage Components enables spare parts inventories and carrying costs to be reduced.

Large Axial Travel Capability maximizes operating life; sealing integrity maintained through all plant transient scenarios.

Nuclear Power Pumps

Flowserve Pumps for Nuclear Power – Pumps – Seals – Engineering and Technical Support – Re-rates and Upgrades – Aftermarket Services

A New Line of Defense

Article on the addition of the passive abeyance seal to the N-Seal nuclear primary pump seal. Appeared in Nuclear Engineering International in October, 2013

Flowserve DVSR Between Bearings Pump

Flowserve DVSR Between Bearings Pump

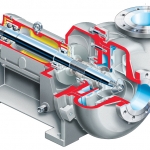

The DVSR is a radially split single stage pump with between bearings that is intended for continuous operation in heavy duty, high pressure pipeline applications. Based on our DVSH axially split pump family, which includes over 100 hydraulics, the DVSR is the optimum solution when an axially split pump is restricted.

- Radially split cases can operate at far lower specific gravities and much higher pressures than comparable axially split cases.

- Sucker and Discharge Nozzles are integrally cast in casing, allowing pumps to be disassembled without disrupting the piping.

- The Double Volute Design lowers hydraulic radial forces in all circumstances, even at the lowest flow.

- Double Suction: The impeller provides low NPSHr and hydraulic axial balance.

- ISO 10549 / API 682 Seal Chambers accommodate a wide range of seal configurations while ensuring adequate flow around the seal faces.

- Under the first critical speed, the heavy-duty shaft construction ensures trouble-free operation.

- Standard renewable casing and impeller wear rings provide hydraulic stability and high operating efficiency.

DVSH Heavy-Duty, Between Bearings, Axially Split, Single-Stage, Double-Suction Pump – Brochure

- The Dynamic Thruster Balancing System eliminates the need for thrust bearings with operating costs are reduced while pump efficiency, dependability, and lifespan improve.

- The minimum thickness of vacuum-certified Pure ETFE casing liners is 3 mm (0.125 in) while the one-piece ETFE impeller and inner magnet assembly guarantees maximum torque transfer while also simplifying maintenance and eliminating balancing.

- Enclosed impeller with unobstructed eye has low NPSHR and high efficiency.

- Double-sealed inner magnets provide unparalleled resistance to corrosive infiltration since they are sheathed in 316L stainless steel before being injection molded into the impeller assembly.

- One-piece composite confinement. The shell is made of Aramid and carbon fiber reinforced ETFE for maximum corrosion resistance and leakage protection.

- Zero eddy current losses in composite construction ensures maximum efficiency.

- Static Cantilevered Pump The shaft is large enough to accommodate all radial strains and is designed to increase flow while reducing NPSHR. Interchangeability across sizes reduces inventory costs and streamlines maintenance.

- Reliable performance up to 30% solids content of 0.13 mm is dependent on outstanding solid handling capabilities.

Specification:

- Flows to 360 m3/h (1,585 gpm)

- Heads to 153 m (500 ft)

- Pressures to 25 bar (362 psi)

- Temperatures from -29°C to 120°C (-20°F to 250°F)

- Solids to 30% by volume

- Spherical size to 6.35 mm (0.25 in)

INNOMAG TB-MAG Application

Typical applications include chemical processing, reactor feed, chlorine-alkali, chemical waste treatment, scrubber systems, tank car loading and unloading, metal finishing (pickling), etching, and plating.

INNOMAG TB-MAG designed to boost performance.

- Dynamic thrust balancing technology ensures optimal performance throughout all flow range.

- Back wear rings limit solids to 0.127 mm (0.005 in) for superior solids handling capacity.

- Only clean process fluid should be allowed to enter the bearings and shaft for optimal cooling and lubrication.

- The rotomolded ETFE liner provides a mechanical interface with the casing and is rated for complete vacuum; the double-sealed inner magnet assembly shields the magnets from corrosive permeation with a hermetically sealed stainless steel sheath.

- The roto molding process allows for advanced volute designs that increase efficiency.

INNOMAG TB-MAG Pump – Brochure

INNOMAG TB-MAG Pump – Poster

INNOMAG TB-MAG Pump Poster (with ISO upgrades)

Ready to optimize your systems with the INNOMAG TB-MAG pump? Contact us right now for more information or to request a quotation!

PVML-Mag API 685, Overhung, Vertical In-line, Magnetic Drive Pump

PVML-Mag API 685, Overhung, Vertical In-line, Magnetic Drive Pump

| Brand: | Flowserve |

|---|---|

| Description: | The Flowserve PVML-MAG pump is the magnetic drive configuration of the close coupled, vertical in-line PVML design. Hydraulics… |

The Flowserve PVML-MAG pump is the magnetic drive configuration of the close coupled, vertical in-line PVML design. Hydraulics are custom tuned to duty points using interchangeable diffuser channels.

- Applications:

Petrochemical Processing, Petroleum Distribution, Acid Transfer, Difficult-to-Seal Liquids, General Purpose, Gas Industry Service , Water, Toxic Services, Valuable Liquids, Emissions Reduction - Industries:

Volatile Organic Compounds, Acid Transfer, Auxiliary - Standards:

API610

Contamination-Free Pumpage without use of external fluid.

Hydraulics Are Custom Tuned for the actual duty point by project-specific design of multi-channel diffuser.

Diffuser Technology provides low vibration, wide flow range, virtually zero radial loads, and very low shaft deflection at any flow rate.

Dynamically Balanced Impeller limits vibration and assures smooth operation over wide flow range.

Features:

- Product lubricated silicon carbide radial and axial thrust slide bearings

- Venting of slide bearings area

- Positively locked, anti-rotation impeller nut with threads unexposed to pumped fluid

- Other configurations

- PVML (standard sealed)

- Operating parameters

- Flows to 500 m3/h (2200 gpm)

- Heads to 275 m (900 ft)

- Pressures to 40 bar (600 psi)

- Temperatures to 200°C (400°F)

RTN-R Certificate Hengelo

RTN-R Hengelo Pump type: SC7, SCE, TC, PHL, SJA, PHL-MAG, PVML, PVML-MAG, HGT, LHGT, HDHD, VOA, sVSO, VSO, VOP

PVML Vertical In-Line Process Pumps Bulletin

Flowserve PVML Vertical In-Line Process Pump – ISO 13709/API 610 (OH5)

CVP, Concrete Volute Pump (BSP & BCV) Vertical

CVP, Concrete Volute Pump (BSP & BCV) Vertical

Brand |

Description |

| Flowserve | The CVP (BSV and BCV) Vertical Concrete Volute Pumps are engineered for high-efficiency and durability. These pumps are designed to handle demanding applications in various industries, offering optimal performance for both large-scale water and wastewater projects. The vertical design ensures a compact footprint while maintaining a high flow capacity, making them ideal for tight spaces. With advanced features and robust construction, these Concrete Volute Pumps are reliable solutions for managing high-volume pumping needs. |

CVP (BSV & BCV)

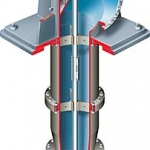

The Flowserve BSV and BCV concrete volute pumps are vertical, wet pit designs used for large flow applications requiring continuous operation. The massive concrete volute substantially reduces noise and vibration, offers high corrosion and erosion resistance, significantly increasing pump life.

- Applications: Cooling Water (power), Ground Water Development and Irrigation, Flood Control, Shipping, Water Supply and Distribution (water), Nuclear Service

- Industries: General Industries, Water Resources, Power Generation

Verical dry-pit design consists of a removable, metallic pump pullout unit within prefabricated concrete volute.

The suction bell is connected to a preformed, concrete intake suction box.

Massive concrete pump construction substantially reduces noise and vibration and also provides excellent corrosion and erosion resistance.

Impeller Options include open mixed flow and closed mixed flow types. Pumps may be driven directly or through a gearbox.

Operating Parameters

- Flows to 115 000 m3/h (500 000 gpm)

- Heads to 45 m (147 ft)

DMX ISO 13709/API 610 (BB3) Between Bearings, Single Case, Axially Split, Multistage Pump

DMX ISO 13709/API 610 (BB3) Between Bearings, Single Case, Axially Split, Multistage Pump

Brand |

Description |

| Flowserve | The Flowserve DMX is an axially split, multistage pump designed to DMX ISO 13709/API 610 (BB3), latest edition. DMX pumps are particularly suited for high-pressure applications, delivering reliable performance and efficiency in demanding environments. |

DMX ISO 13709/API 610 (BB3) Between Bearings, Single Case, Axially Split, Multistage Pump

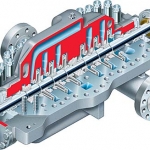

The Flowserve DMX is an axially split, multistage pump designed to API 610 (BB3), latest edition. DMX pumps are particularly well suited for process charge, pipeline and injection services where uncompromising reliability over wide ranges is imperative.

- Applications:

Ground Water Development and Irrigation, Gas to Liquids, Hydraulic Press (metals), Hydrocracking, Hydrotreating, Boiler Feed, LNG, Boiler Feed (pulp and paper), Crude, Product and CO2 Pipeline, Nuclear Service, Desalination, Renewable Fuel Production, Descaling, Water Supply and Distribution (water), Dewatering and Water Supply (mining), Water Supply and Treatment (oil and gas), Distillation (oil and gas), Water and CO2 Injection, Drilling and Production, FPSO, Gas Treating and Sulfur Recovery, Heavy Oil, Oil Sands and Shale - Industries:

Oil and Gas, Power Generation, Primary Metals, Mining, Water Resources, Chemical Processing, Pulp and Paper

Pump Design incorporates double volute hydraulic passages for radial thrust balance and opposed impeller mounting for axial thrust balance.

Seal Chambers to API 682 dimensional criteria allow for installation of cartridge design single, dual unpressurized and dual pressurized mechanical seals to meet safety and environmental requirements.

Shaft Options include double extension for connection to auxiliary pumps or hydraulic turbines, and special shaft end machining for hydraulic fitted couplings.

Baseplates Designs and Pump Packages engineered to contract requirements.

Dynamic Balancing and TIR Verifications on assembled rotors assure optimum mechanical performance throughout the operating range.

Features:

- Choice of bearings

- Ball radial and thrust

- Sleeve radial and ball thrust

- Sleeve radial and tilting pad thrust

- Tilting pad radial and tilting pad thrust

- Choice of materials

- Carbon steel

- 12% chrome

- Austenitic and duplex stainless steels

- Monel

Operating parameters

- Flows to 2950 m3/h (13 000 gpm)

- Heads to 2130 m (7000 ft)

- Pressures to 275 bar (4000 psi)

- Temperatures to 200°C (400°F)

- Speeds to 6000 rpm

BP Diffuser Casing, Multistage, Process Barrel Pump ISO 13709/API 610 (BB5

BP Diffuser Casing, Multistage, Process Barrel Pump ISO 13709/API 610 (BB5

| Brand: | Flowserve |

|---|---|

| Description: | Fully compliant with the latest edition of ISO 13709/API 610 (BB5), the BP Diffuser Casing Multistage Process Double-case pump is a diffuser-style pump that is well-suited for high-pressure industrial applications, including oil and gas processing, power generation, and chemical industries. Designed with precision-cast components, the BP Diffuser Casing Multistage Process Double-case pump ensures exceptional efficiency, durability, and reliability in demanding environments. |

Horizontal multistage pump

Horizontal multistage pump is a diffuser style pump that is well-suited for high temperature and high pressure services. In particular, it is ideal for boiler feed, descaling, decoking and reactor charge applications.

-

Applications:

Auxiliary (chemical), Water and CO2 Injection, Boiler Feed

-

Industries:

Chemical Processing, Power Generation, Oil and Gas

-

Standards:

API610

Optimized Multi-Vane Diffuser and Channel Ring Design results in balanced radial loads and precise hydraulic performance over the entire flow range, including partial-load operation.

Tandem Impeller Design increases rotor stability and facilitates maintenance by permitting replacement of a single casing stage.

Dynamically Balanced Impellers are precision cast to improve hydraulic efficiency and performance repeatability.

Straight Style Balance Drum simplifies assembly since no axial setting is required.

Operating Parameters

- Flows to 1050 m3/h (4620 gpm)

- Heads to 3500 m (11 480 ft)

- Discharge pressures to 295 bar (4260 psi)

- Temperatures to 425°C (800°F)

- Speeds to 6000 rpm

Hydraulic Decoking Systems Control Valve

Hydraulic Decoking Systems Control Valve

| Brand: | Flowserve |

|---|---|

| Description: | The Flowserve decoking control valve controls the flow from the jet pump with a single valve providing three distinct features:… |

The Flowserve decoking control valve controls the flow from the jet pump with a single valve providing three distinct features: recirculation flow control, pre-fill and full flow to the decoking tool nozzles.

- Applications:

Decoking, Petroleum Production and Refining - Industries:

Heavy Oil and Upgrading, Delayed Coking

Three Distinct Functions

- Recirculation (bypass) flow control for pump protection

- Pre-fill of decoking lines, hoses, manifolds, etc., at a predetermined flow rate to prevent water hammer

- Full flow to the decoking tool nozzles. Very low pressure drop (high Kv [Cv]) in full flow for reduced energy consumption

Features and Benefits

- Cost-effective solution

- Design and maintenance simplicity with minimal moving parts

- No foundation required

Design Features

- Long Stroke, Single Stem Operation

- Assures no unwanted overlap of functions

- Non-Clogging Design

- Passes particles up to 3 mm (1/8 in)

- Compact Design

- Simplifies installation. Suitable for direct mounting on the jet pump

- Stainless Steel

- Inlaid at all gasket surfaces, option for fully lined body

- Valve Stem Sealing

- Using low friction elastomer rings. No adjustment…no packing required

- Proven, Replaceable, Durable Soft Seals

- Assures zero leakage with water and coke fines – no lapping required during repairs

- Instant Return

- To any operating mode upon command

- Actuation

- Limitorque® motor operator is standard. Optional double-acting pneumatic actuator with positioner is available with 5.5 bar (80 psi) to 7 bar (100 psi) air supply requirement

- Decoking Valve Upgrade Options

- A Flowserve decoking expert can help specify appropriate materials and design enhancements, controls and instrumentation for specific service requirements

Remote and Automated Hydraulic Decoking Systems

Remote and Automated Hydraulic Decoking Systems

Hydraulic Decoking System Equipment Bulletin

Flowserve Hydraulic Decoking System Equipment

Decoking System Equipment Innovation Poster

Flowserve Decoking Poster – Innovation from the Global Leader in Hydraulic Decoking (11″ x 17″)

Hydraulic Decoking Systems – Decoking Control Valve

Flowserve Hydraulic Decoking Systems – Decoking Control Valve

Limitorque MX Series- The Next Generation in Smart Multi-Turn Actuation Brochure

Limitorque MX Electronic Valve Actuator The Next Generation in Smart Multi-turn Actuation brochure

Hydraulic Decoking System Rotary Joint

Hydraulic Decoking System Rotary Joint

Molten Salt VTP Pump

Molten Salt VTP Pump

| Brand: | Flowserve |

|---|---|

| Description: | Built upon the popular VTP pump, Flowserve Molten Salt VTP was designed using advanced thermal mapping software to ensure… |

Built upon the popular VTP pump, Flowserve Molten Salt VTP was designed using advanced thermal mapping software to ensure adequate heat dissipation and mitigate distortion. Available in single or multistage diffuser designs.

- Applications:

Molten Salt Transfer - Industries:

Power Generation

Key Features and Benefits:

- Low pump submergence allows for greater energy generation.

- Low NPSHR for enhanced suction performance.

- Excellent heat dissipation design prevents distortion at high temperatures.

- Advanced fluid sealing system protects against fluid leakage and reduces heat conduction.

- Materials engineered to equalize thermal growth and forestall distortion.

Operating Parameters

- Flows to 13 600 m3/h (60 000 gpm)

- Heads to 530 m (1740 ft)

- Pressures to 100 bar (1450 psi)

- Temperatures to 600°C (1100°F)

- Settings to 20 m (65 ft)

Concentrated Solar Power Pumps

Flowserve Pumps for Concentrated Solar Power – Parabolic Trough – Power Tower

VCT Vertical Mixed Flow

VCT Vertical Mixed Flow

| Brand: | Flowserve |

|---|---|

| Description: | VCT pumps are designed for extended operation in services where large capacities are required at relatively low pressures.… |

VCT pumps are designed for extended operation in services where large capacities are required at relatively low pressures. Ideal for wet pit installations, VCTs offer multiple hydraulic combinations and design features to suit application needs.

- Applications:

Flood Control, Ground Water Development and Irrigation, Shipping, Water Supply and Distribution (water), Water Supply and Treatment (oil and gas), Dewatering and Water Supply (mining), Auxiliary (chemical), Condensate Extraction, Cooling Water (metals), Cooling Water (power), Desalination, Agriculture - Industries:

Chemical Processing, General Industries, Mining, Water Resources, Power Generation, Primary Metals, Oil and Gas

Five-Mitered Elbow Discharge Head is designed to accept continuous system reaction forces and reduce friction loss.

Three-Piece, Rigid Adjustable Motor Coupling provides a convenient means of maintaining optimum impeller clearance.

Outer Flanged Column utilizes precision rabbet fits to ensure proper alignment of each section and is fabricated to meet customer materials requirements.

Inner Column (Enclosing Tube) is internally pressurized to lubricate bearings and prevent shaft and bearing damage during operation.

Semi-Open Impeller and Shroud Design offer easily renewable clearances for optimum efficiency. Dynamic balancing of the finish machined impeller ensures low vibration levels.

Operating Parameters

- Flows to 181 700 m3/h (800 000 gpm)

- Heads to 110 m (350 ft)

- Sizes from 1200 mm (48 in) to 3380 mm (133 in)

Concentrated Solar Power Pumps

Flowserve Pumps for Concentrated Solar Power – Parabolic Trough – Power Tower

Power Generation Pumps

Flowserve Pumps for Power Generation – Combined cycle, fossil fuels and nuclear

Nuclear Power Pumps

Flowserve Pumps for Nuclear Power – Pumps – Seals – Engineering and Technical Support – Re-rates and Upgrades – Aftermarket Services

VCT Vertical Centrifugal Pumps User Instructions

Installation, Operation, & Maintenance for VCT Pumps

VTP Vertical Turbine, Wet Pit Pump

VTP Vertical Turbine, Wet Pit Pump

| Brand: | Flowserve |

|---|---|

| Description: | The VTP vertical turbine pump is a diffuser type, single or multistage design for continuous service in wet pit and deep… |

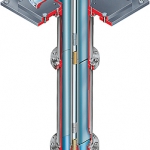

The VTP vertical turbine pump is a diffuser type, single or multistage design for continuous service in wet pit and deep well applications. With more than 300 bowl and impeller designs, the VTP provides unsurpassed hydraulic coverage to ensure the best pump selection for a wide variety of services.

- Applications:

Descaling, Flood Control, Drilling and Production, FPSO, Geothermal Well Services, Ground Water Development and Irrigation, LNG, Agriculture, Nuclear Service, Snowmaking, Offsites and Waste Treatment, Renewable Fuel Production, Shipping, Transformer Cooling, Water Treatment, Auxiliary (chemical), Water Supply and Distribution (water), Auxiliary Services (power), Cooling Water (metals), Cooling Water (power), Dewatering and Water Supply (mining) - Industries:

General Industries, Mining, Oil and Gas, Chemical Processing, Primary Metals, Water Resources, Power Generation

VTP pumps are available in a wide variety of configurations, constructions and materials to suit application requirements. Among the options are:

- Open or enclosed lineshaft construction

- Enclosed or semi-open impellers, keyed or collet mounted

- Bowl and enclosed impeller wear rings

- Cast iron or fabricated steel discharge heads

- Sealing configurations for open lineshaft construction

- Packed box with flexible graphite packing

- Single or dual mechanical seal

- Sealing configurations for enclosed lineshaft construction

- Enclosing tube tension assembly for oil lubrication

- Water injection packing assembly

- Above ground or below ground discharge flanges

- Multiple drivers

- Electric motors, solid or hollow shaft

- Engines with right angle gear drives

- Steam turbines

- Separate axial thrust bearing assembly

- Standard and ISO 13709/API 610 (VS1), latest edition configurations

Operating Parameters

- Flows to 13 600 m3/h (60 000 gpm)

- Heads to 700 m (2300 ft)

- Pressures to 100 bar (1450 psi)

- Temperatures from -45°C (-50°F) to 300°C (570°F)

- Sizes from 150 mm (6 in) to 1375 mm (55 in)

- Settings to 365 m (1200 ft)

VTP User Instructions

VTP Vertical Turbine Pumps – User Instructions: E, S, and A series VTPs in wet pit and suction barrel designs from 50 mm (6 in) to 1300 mm (52 in) with single or multiple stages. Does not include cryogenic pumps or those with thrust bearing assemblies.

VTP Vertical Turbine Pumps (With Thrust Bearing Assemblies) User Instructions

VTP Vertical Turbine Pumps With Thrust Bearing Assemblies – Installation, Operation & Maintenance Instructions: E, S, and A series VTPs in wet pit and suction barrel designs from 50 mm (6 in) to 1300 mm (52 in) with single or multiple stages. Does not include cryogenic service pumps.

VTP Pump Poster

Flowserve VTP Pumps – Vertical Turbine, Wet-Pit Pump

Concentrated Solar Power Pumps

Flowserve Pumps for Concentrated Solar Power – Parabolic Trough – Power Tower

Nuclear Power Pumps

Hydraulic Decoking Systems Drill Stem

Hydraulic Decoking Systems Drill Stem

Brand |

Description |

| Flowserve | Drill stems carry torque from the rotary joint to the cutting tool together with water. Extremely durable and with a side load strength four times higher than similar welded drill stem designs are Flowserve threaded drill stems. |

Flowserve Drill Stem Hydraulic Decoking Systems in Mechanical Decoking Applications

Flowserve threaded drill stems are extremely durable for decoking service with a side load strength four times greater than comparable welded drill stem designs.

- Applications:

Petroleum Production and Refining, Decoking

Drill Stem Hydraulic Decoking Systems Features and Benefits

- Fabricated from ASTM A-519 Gr. 4140 steel tubing in 6-meter (20-foot) sections

- Hot process expansion maintains wall thickness of tube through the female threaded end and reduces stress in the area of thread engagement

- API 5 CT 6-5/8 in Extreme-Line threads

- Heat treated for maximum strength

- Swaged female ends to maintain thickness throughout

Specifications

- 7-inch OD x 3/4–inch wall thickness

- Heat treated to Rc 29-37

- Multiple end attachment options for both rotary joint and cutting tool

- Compact flange

- 3000 lb and 5000 lb unibolt couplings with integral threads

- 1500 lb RTJ, 2500 lb RTJ and 2500 lb flange connections

Hydraulic Decoking Systems AutoShift™ Cutting Tool

Hydraulic Decoking Systems AutoShift™ Cutting Tool

| Brand: | Flowserve |

|---|---|

| Description: | The AutoShift combination decoking tool makes remote drum decoking feasible by removing the operator from the cutting deck.… |

The AutoShift combination decoking tool makes remote drum decoking feasible by removing the operator from the cutting deck. Boring and cutting mode shifting is accomplished automatically and safely within the drum by water pressurization and depressurization.

- Applications:

Petroleum Production and Refining, Decoking - Industries:

Heavy Oil and Upgrading, Delayed Coking

Features and Benefits

The AutoShift combination decoking tool provides numerous benefits to hydraulic decoking operations:

- Improved Operator Safety – Remote operation eliminates operator exposure to high-pressure water, steam eruptions, H2S vapors and mechanical hazards

- Greater System Automation – Automatic shifting coupled with computerized controls and instrumentation enables total process automation

- Reduced Cycle Times – Automatic shifting within the drum saves 30 minutes or more per cycle

- Improved Efficiency – The decoked vessel returns to service more quickly and safely

- Easier Maintenance – AutoShift features a self-cleaning design that flushes coke fines from the shifting mechanism and jet ports

- Shifting Flexibility – “Stuck” tools can be freed up quickly within the drum by automatically shifting between boring and cutting modes

- Manual Shift Feature – If necessary, AutoShift can quickly and easily shift modes as with traditional combination cutting tools

- Retrofit Cartridge Assembly – Existing Flowserve (i.e., Worthington, Pacific) and non-Flowserve hydraulic decoking systems can upgrade to AutoShift technology

Remote and Automated Hydraulic Decoking Systems

Remote and Automated Hydraulic Decoking Systems

Hydraulic Decoking System Equipment Bulletin

Flowserve Hydraulic Decoking System Equipment

Decoking System Equipment Innovation Poster

Flowserve Decoking Poster – Innovation from the Global Leader in Hydraulic Decoking (11? x 17?)

Hydraulic Decoking Systems – Decoking Control Valve

Flowserve Hydraulic Decoking Systems – Decoking Control Valve

Hydraulic Decoking System Rotary Joint

Hydraulic Decoking Systems Crosshead (Free Fall Arrestor)

Hydraulic Decoking Systems Crosshead (Free Fall Arrestor)

Brand |

Description |

| Flowserve | Flowserve Crosshead Free Fall Arrestor System is an advanced solution designed to enhance safety and efficiency in Hydraulic Decoking Systems. The Free Fall Arrestor System ensures that the cutting assembly in decoking operations is safely suspended and can be quickly stopped in case of rope tension failure, preventing damage to personnel and equipment. Flowserve’s technology is engineered for robust, high-performance operations in demanding industrial environments like petroleum refining and heavy oil upgrading. |

Crosshead Free Fall Arrestor for Hydraulic Decoking Systems

The Flowserve Crosshead Free Fall Arrestor unit plays a critical role in guiding and centering the rotary joint-drill stem-cutting tool assembly within the coke drum. The Crosshead is engineered to safely absorb all torque loads typically sustained during cutting operations. Designed for Hydraulic Decoking Systems, this solution enhances operational safety and efficiency in decoking applications.

Applications:

- Petroleum Production and Refining

- Decoking (Hydraulic Decoking Systems)

Industries:

- Heavy Oil and Upgrading

- Delayed Coking

Features and Benefits

The Flowserve Crosshead Free Fall Arrestor System is available in two distinct designs:

- Shoe-type Crosshead: Features two rectangular-shaped shoes that slide within the structure’s beams for smooth operation.

- Wheeled-type Crosshead: Incorporates four wheel blocks with spring-loaded guides in two planes that move along a track attached to the structure’s beams.

The Free Fall Arrestor (FFA) is built into the crosshead, providing an added layer of protection by preventing the cutting assembly from falling in the event of suspension failure. This safety mechanism does not require electric or pneumatic connections for activation, ensuring seamless operation even under challenging conditions.

Key safety and operational benefits include:

- Prevents cutting assembly equipment from falling and potentially damaging the cutting deck, offering superior protection for both personnel and equipment in case of steel wire rope failure.

- Safeguards ancillary equipment from damage caused by falling machinery.

- FFA automatically disengages once the required rope tension is restored, ensuring safe and effective operation.

Other essential components included in the Crosshead Free Fall Arrestor System:

- Winch

- Winch wire rope

- Wire rope tension monitoring (tensiometers)

- Lead, crown, traveling, and guide blocks

Decoking Winch

Decoking Winch

Brand |

Description |

| Flowserve | The Decoking System Winch is designed for coke cutting, controlling the cutting assembly by raising and lowering the cutting tool in the coke drum. It ensures safe and reliable operation under demanding conditions and is available with pneumatic, hydraulic, or electric drive options, with electric-over-air controls for remote cutting. |

The decoking winch is specifically designed for use in coke cutting to raise and lower the cutting tool in the coke drums. Several unique features are incorporated to assure safe, reliable operation in the most demanding environments.

- Applications:

Petroleum Production and Refining, Decoking - Industries:

Delayed Coking, Heavy Oil and Upgrading

Features and Benefits

The decoking winch is specifically designed for use in coke cutting. It delivers large hoisting power with a high design factor and variable line speed. The fabricated steel drum and frame assembly, complete with a planetary gearbox, fail-safe wet (oil bath) disc brake, and automatic drum brake, provides safe operation in the most demanding environments. Other features include a drum lock, an oversized drum barrel to promote longer wire rope life, a remote throttle valve for variable speed and safe load control, and auxiliary brake release for precise lowering control. To assist in achieving consistent wire rope spooling and longer wire rope life, the following accessories are included:

- Spiral grooved drums

- Press rollers

- Level winds

The winch is available in pneumatic, hydraulic or electric drive.

Hydraulic Decoking Systems Tensiometer / Load Cell

Hydraulic Decoking Systems Tensiometer / Load Cell

| Brand: | Flowserve |

|---|---|

| Description: | The Flowserve compression type tensiometer replaces typical designs used for measuring cable tension. The result is a more… |

The Flowserve compression type tensiometer replaces typical designs used for measuring cable tension. The result is a more practical load measurement system with many safety, operation and maintenance advantages.

- Applications:

Petroleum Production and Refining, Decoking - Industries:

Heavy Oil and Upgrading, Delayed Coking

Features and Benefits

The Flowserve compression type tensiometer puts the load measuring device in a compressive mode rather than in tension and provides the following benefits:

- All parts are manufactured of NACE grade corrosion-resistant stainless steel at hardness levels that mitigate stress corrosion cracking

- Direct cable attachment capability eliminates the need for commercial eye bolts

- May be located at the cutting deck for easy maintenance access

- Load cell can be unloaded without disconnecting the cable, allowing the strain gage amplifier to be zero adjusted with all components in place

- Removal and replacement of tensiometer can be accomplished without disconnecting the cable

- Design is compatible with existing strain gauge amplification modules and display units

Remote and Automated Hydraulic Decoking Systems

Remote and Automated Hydraulic Decoking Systems

Hydraulic Decoking System Equipment Bulletin

Flowserve Hydraulic Decoking System Equipment

Decoking System Equipment Innovation Poster

Flowserve Decoking Poster – Innovation from the Global Leader in Hydraulic Decoking (11? x 17?)

Hydraulic Decoking Systems – Decoking Control Valve

Flowserve Hydraulic Decoking Systems – Decoking Control Valve

Hydraulic Decoking System Rotary Joint

Hydraulic Decoking Systems Latching Mechanisms

Hydraulic Decoking Systems Latching Mechanisms

| Brand: | Flowserve |

|---|---|

| Description: | Flowserve latch mechanisms enable stowing of the crosshead when not in use, providing a safe and practical way to remove… |

Flowserve latch mechanisms enable stowing of the crosshead when not in use, providing a safe and practical way to remove tension on the cable and winch.

- Applications:

Petroleum Production and Refining, Decoking - Industries:

Delayed Coking, Heavy Oil and Upgrading

Features:

The latching mechanism must be charged electrically to disengage the interface lever from the travel rails to allow the crosshead to release.

- Electrically actuated with option for pneumatic

- 24-volt signal for latching operations

- Fail safe mode is locked

- Latch does not need to be energized to allow parking of the crosshead

Scorpion FLS 600 Drill Stem Tensioner

Scorpion FLS 600 Drill Stem Tensioner

| Brand: | Flowserve |

|---|---|

| Description: | The Flowserve Scorpion FLS 600 hydraulic decoking drill stem tensioner improves safety and reduces disassembly and reassembly… |

The Flowserve Scorpion FLS 600 hydraulic decoking drill stem tensioner improves safety and reduces disassembly and reassembly time compared to labor-intensive traditional methods.

- Applications:

Decoking, Petroleum Production and Refining - Industries:

Delayed Coking, Heavy Oil and Upgrading

Features and Benefits

The Scorpion FLS 600 replaces conventional labor intensive equipment using multiple wrenches and chains with a single unit that is both safer and easier to operate. Its compact, single-unit design increases portability and alleviates the process of getting equipment and crews in place. The FLS 600’s built-in backup removes the need for a permanent anchor and enables operation by a single individual without risk to personnel safety. Features include:

Improved safety over manual chain tongs

Easy to operate drill stem tensioner provides a powerful, versatile method for making up and breaking out drill stem sections; instantly changes from break-out to make-up mode; portable and compact design.

Built-in backup does not require permanent anchor for operations.

Adjustable spacing between arms increases flexibility.

Multiple power pack options are available, including: electric, pneumatic and hydraulic.

Chain design enables adjustments compatible with all Flowserve drill stems.

Remote and Automated Hydraulic Decoking Systems

Remote and Automated Hydraulic Decoking Systems

Hydraulic Decoking System Equipment Bulletin

Flowserve Hydraulic Decoking System Equipment

Decoking System Equipment Innovation Poster

Flowserve Decoking Poster – Innovation from the Global Leader in Hydraulic Decoking (11? x 17?)

Hydraulic Decoking Systems – Decoking Control Valve

Flowserve Hydraulic Decoking Systems – Decoking Control Valve

Hydraulic Decoking System Rotary Joint

Isolation and Bleed Valves

Isolation and Bleed Valves

| Brand: | Flowserve |

|---|---|

| Description: | Customized decoking ball valves are used to manage cutting water flow to the coke drums and to relieve drum pressure. The… |

Customized decoking ball valves are used to manage cutting water flow to the coke drums and to relieve drum pressure. The valve designs incorporate unique features that provide long life and safe operations.

- Applications:

Petroleum Production and Refining, Decoking - Industries:

Heavy Oil and Upgrading, Delayed Coking

Features and Benefits

Isolation valves divert the cutting fluid to the correct drum scheduled for decoking while bleed valves relieve pressure on the closed drums. Valve material is specially optimized for long service life in decoking operations. ANSI 2500 RTJ flanges are standard with higher pressure ratings available.

Limitorque actuators with limit switches operate the valves and provide automatic control. A manual override is provided for operation in the event of a power failure. The valves include locking pins for safe position security during maintenance.

Remote and Automated Hydraulic Decoking Systems

Remote and Automated Hydraulic Decoking Systems

Hydraulic Decoking System Equipment Bulletin

Flowserve Hydraulic Decoking System Equipment

Decoking System Equipment Innovation Poster

Flowserve Decoking Poster – Innovation from the Global Leader in Hydraulic Decoking (11? x 17?)

Hydraulic Decoking Systems – Decoking Control Valve

Flowserve Hydraulic Decoking Systems – Decoking Control Valve

Limitorque MX Series- The Next Generation in Smart Multi-Turn Actuation Brochure

Limitorque MX Electronic Valve Actuator The Next Generation in Smart Multi-turn Actuation brochure

Hydraulic Decoking System Rotary Joint

Hydraulic Decoking Systems Video Monitoring System

Hydraulic Decoking Systems Video Monitoring System

| Brand: | Flowserve |

|---|---|

| Description: | Video monitoring systems provide critical feedback to operators and are an essential part of remotely operated coke cutting… |

Video monitoring systems provide critical feedback to operators and are an essential part of remotely operated coke cutting systems from Flowserve.

- Applications:

Decoking, Petroleum Production and Refining - Industries:

Heavy Oil and Upgrading, Delayed Coking

Features:

Area-rated video cameras placed on the cutting deck give the operator a view of the top of the coked drum. Cameras also monitor the chute to provide feedback on drum cleaning while others provide a view of cutting operations from across the coke pit. All cameras have full tilt and pan capability and deliver video signal to remote cutting location on two or more monitors.

Remote and Automated Hydraulic Decoking Systems

Remote and Automated Hydraulic Decoking Systems

Hydraulic Decoking System Equipment Bulletin

Flowserve Hydraulic Decoking System Equipment

Decoking System Equipment Innovation Poster

Flowserve Decoking Poster – Innovation from the Global Leader in Hydraulic Decoking (11? x 17?)

Hydraulic Decoking Systems – Decoking Control Valve

Flowserve Hydraulic Decoking Systems – Decoking Control Valve

Hydraulic Decoking System Rotary Joint

Hydraulic Decoking Systems Rotary Joint

Hydraulic Decoking Systems Rotary Joint

| Brand: | Flowserve |

|---|---|

| Description: | The Flowserve Pacific® heavy-duty rotary joint is robustly designed to support the suspended loads experienced… |

The Flowserve Pacific® heavy-duty rotary joint is robustly designed to support the suspended loads experienced in coking units. Its function is to transmit cutting fluid from the stationary hose connection to the drill stem and cutting tool. Flowserve is continually upgrading its rotary joint to accommodate increasingly higher cutting pressure requirements.

- Applications:

Petroleum Production and Refining, Decoking - Industries:

Heavy Oil and Upgrading, Delayed Coking

Features and Benefits

- Two flange sizes – The rotary joint is available with 125 mm (5 in) 250 PN (1500 lb) or 400 PN (2500 lb) inlet flanges and with optional 150 mm (6 in) Unibolt® or compact flange connections to match the drill stem connector

- Cast single-piece gooseneck eliminates welds and reduces corrosion

- Rotary joint drive options –

- Air piston motor

- Hydraulic

- E-motor (with VFD)

- Dual Seal

- Increased reliability with a four-year design life

- Switching from the primary seal to the secondary seal allows for planned maintenance in the event of a seal failure

- Simple installation reduces downtime

- Retrofit option for all Flowserve rotary joints

- Rotary joint upgrade options

- Convert packing to seal rings

- Convert vertical air motor to horizontal motor with right angle gear

- Upgrade Unibolt coupling to direct connect with drill stem

- Add second bearing for right angle drive shaft

- Convert to integral gooseneck and support cage

- Add rotary joint stiffeners

Operating Parameters

Two models available:

- Pressures to

- 205 bar (3000 psi)

- 430 bar (6230 psi)

- Speeds of 2 to 17 rpm

- Rotates 30 m (100 ft) to 45 m (140 ft) drill stem lengths

- Carries axial hydraulic loads in the magnitude of 190 000 J (140 000 ft-lb) through its main thrust bearing

- Seals hydraulic pressure against atmosphere

®Unibolt is a registered trademark of Cameron International Corporation

Remote and Automated Hydraulic Decoking Systems

Remote and Automated Hydraulic Decoking Systems

Hydraulic Decoking System Equipment Bulletin

Flowserve Hydraulic Decoking System Equipment

Decoking System Equipment Innovation Poster

Flowserve Decoking Poster – Innovation from the Global Leader in Hydraulic Decoking (11? x 17?)

Hydraulic Decoking Systems Drill Stem Guide and Shroud Assembly

Hydraulic Decoking Systems Drill Stem Guide and Shroud Assembly

| Brand: | Flowserve |

|---|---|

| Description: | The Flowserve drill stem guide and shroud can accommodate up to 305 mm (12 inches) of overall lateral misalignment. The innovative… |

The Flowserve drill stem guide and shroud can accommodate up to 305 mm (12 inches) of overall lateral misalignment. The innovative design rides on the drill stem and fully encloses the cutting tool. It diverts dangerous water flow vertically away from operators in the unlikely event a pressurized cutting tool is retracted from the drum or energized while stowed.

- Applications:

Petroleum Production and Refining, Decoking - Industries:

Heavy Oil and Upgrading, Delayed Coking

Features and Benefits

- Fully enclosed 9.5 mm (0.375 inch) thick carbon steel shroud

- Open top allows steam and gas to escape in event of a hot spot blowout

- Can be installed without field welding and without unit shutdown

- Self-aligning, accommodating up to 305 mm (12 inches) of lateral misalignment

- Auto-latching / unlatching feature available; actuation by lowering and raising of drill stem is available

- Loosely mounted on drill stem to permit insertion of the cutting tool into the drum

Remote and Automated Hydraulic Decoking Systems

Remote and Automated Hydraulic Decoking Systems

Hydraulic Decoking System Equipment Bulletin

Flowserve Hydraulic Decoking System Equipment

Decoking System Equipment Innovation Poster

Flowserve Decoking Poster – Innovation from the Global Leader in Hydraulic Decoking (11? x 17?)

Hydraulic Decoking Systems Audio Monitoring System

Hydraulic Decoking Systems Audio Monitoring System

| Brand: | Flowserve |

|---|---|

| Description: | Audio monitoring systems provide critical feedback to operators and are an essential part of remotely operated coke cutting… |

Audio monitoring systems provide critical feedback to operators and are an essential part of remotely operated coke cutting systems from Flowserve.

- Applications:

Petroleum Production and Refining, Decoking - Industries:

Heavy Oil and Upgrading, Delayed Coking

Remote and Automated Hydraulic Decoking Systems

Remote and Automated Hydraulic Decoking Systems

Hydraulic Decoking System Equipment Bulletin

Flowserve Hydraulic Decoking System Equipment

Decoking System Equipment Innovation Poster

Flowserve Decoking Poster – Innovation from the Global Leader in Hydraulic Decoking (11? x 17?)

Hydraulic Decoking Systems – Decoking Control Valve

Flowserve Hydraulic Decoking Systems – Decoking Control Valve

Hydraulic Decoking System Rotary Joint

Hydraulic Decoking Systems Coke Drum Monitoring

Hydraulic Decoking Systems Coke Drum Monitoring

Brand |

Description |

| Flowserve | The Flowserve HDS Hydraulic Decoking System improves oil refining safety and efficiency by monitoring coke drums in real-time and confirming total coke removal. The technology minimises downtime, operator exposure, and provides consistent decoking cycles. This technology is essential for hydraulic decoking systems, the Flowserve HDS, and process improvement in oil refining. |

Coke Drum Monitoring Hydraulic Decoking Systems

Flowserve coke drum monitoring systems provide coke cutting personnel with positive confirmation that the coke has been removed and the cutting process can continue. The system can be integrated with the decoking control system for maximum ease-of-use or provided as a stand-alone option.

- Applications:

Petroleum Production and Refining, Decoking - Industries:

Delayed Coking, Heavy Oil and Upgrading

Features and Benefits

Flowserve coke drum monitoring systems provide information that allows the operator to advance the cutting tool at the earliest opportunity, reducing the total time needed to clean the drum. System features and benefits include:

- Permanently mounted vibration sensors – five on the barrel and one on the chute – provide a high signal-to-noise ratio to provide more accurate readouts

- Integrated IPS APEX™ module processes vibration signals and provides clear visualization of coke removal status

- Complete integration with the decoking control system enables full automation of the cutting process

- Operator display indicates:

- Drum cleanliness

- Cutting tool position

- Control valve position

- Drum selection

- Diagnostic information

Decoking Systems

The decoking operating system utilizes state-of the-art programmable controllers, monitoring equipment, and field devices with over 20 years of field-proven design techniques.

- Applications:

Petroleum Production and Refining, Decoking - Industries:

Heavy Oil and Upgrading, Delayed Coking

Decoking Systems Features and Benefits

The basic control system includes a master control panel located near the pump train, a cutting deck panel for each pair of drums, and upper and lower proximity switches to monitor crosshead travel and tool position inside the drums. The system designs meet international standards and unique end-user requirements.

The system provides:

- Monitoring of the pump train and lube oil system with permissive starts, vibration and temperature alarms and shutdowns

- Safety interlocks for the drill stem, decoking valve and isolation valves

- Disabling of the hoist at safe high and low in-drum positions when cutting is in progress

- Display of cutting tool elevation and drill stem position

- Hoist cable tension with under and over tension set points that disable hoist movement

- Discharge pressure of the pump

- Speed indication of the rotary joint

Various options are available for improved system operations, including:

- Remote panels for the programmable controller and the condition monitoring system

- Triple modular redundant processors

- DCS communication

- Flowserve IPS APEX™ drum monitoring to assure complete cutting

- Remote and automated cutting capabilities

SealSentry™ CRC Seal Chambers for ASME (ANSI) Process Pumps

SealSentry™ CRC Seal Chambers for ASME (ANSI) Process Pumps

| Brand: | Flowserve |

|---|---|

| Description: | With SealSentry CRC seal chambers, proven FML technology can now be deployed to extend mechanical seal life in popular pump… |

With SealSentry CRC seal chambers, proven FML technology can now be deployed to extend mechanical seal life in popular pump models from Goulds, Griswold, Peerless and Summit.

- Applications:

HVAC, Volatile Organic Compounds, Auxiliary (chemical), Heavy Oil, Oil Sands and Shale, Waste Processing, Auxiliary Services (power), Hydraulic Press (metals), Water Supply and Distribution (water), Bleach Chemical (pulp and paper), LNG, Water Supply and Treatment (oil and gas), Caustic and Chlor-alkali, Offsites and Waste Treatment, Construction, Cooling Water (metals), Pharmaceuticals, Desalination, Plating, Dewatering and Water Supply (mining), Polymers, Drilling and Production, Renewable Fuel Production, Electronics, Sewage Collection and Treatment, FPSO, Shipping, Acid Transfer, Food Processing, Slurry Processing, Agriculture, Gas Treating and Sulfur Recovery, Solvents, Automotive, Leaching Acid, Water Treatment, Chemical and Liquor (pulp and paper), Nuclear Service, Coatings (pulp and paper), OEM - Industries:

General Industries, Mining, Oil and Gas, Power Generation, Primary Metals, Pulp and Paper, Water Resources, Chemical Processing - Standards:

ASME (ANSI)

With a tapered, oversized bore and integral flow modifiers, the SealSentry CRC seal chamber protects seal faces and components from solids, vapor and excessive heat.

Flow modifiers redirect flow from circumferential to axial.

Balanced flow with low pressure drop in the chamber helps keep solids in suspension, minimizing erosion.

The mechanical seal creates centrifuging action away from its parts.

Solids and slurry merge into the returning flow path and are flushed from the seal chamber.

Increase reliability and lower costs

- Reduce or eliminate the need for costly seal support systems

- Use less expensive seals and flush plans

- Improve mechanical seal performance, reliability and life

- Handle higher solids levels

Flowserve SealSentry™ CRC Seal Chambers

Flowserve SealSentry™ CRC Seal Chambers – FML Seal Chamber Retrofit for ASME (ANSI) Process Pumps

PVML ISO 13709/API 610 (OH5) Vertical In-Line Overhung API Process Pump

PVML ISO 13709/API 610 (OH5) Vertical In-Line Overhung API Process Pump

| Brand: | Flowserve |

|---|---|

| Description: | The Flowserve PVML pump is a vertical, close coupled, in-line design and is fully compliant with the latest API 610 (OH5)… |

The Flowserve PVML pump is a vertical, close coupled, in-line design and is fully compliant with the latest API 610 (OH5) standards. This pump offers a space-saving, alignment-free alternative for many overhung process pumps in upstream and downstream services.

- Applications:

Auxiliary Services (power), Crude, Product and CO2 Pipeline, Distillation (oil and gas), Acid Transfer, Paper Stock, Water Supply and Treatment (oil and gas), FPSO, Gas Treating and Sulfur Recovery - Industries:

Oil and Gas, Pulp and Paper, Power Generation - Standards:

API682, API610

Dynamically Balanced Impeller limits vibration and assures smooth operation over wide flow range. It offers a positively locked, anti-rotation impeller nut with threads unexposed to pumped fluid.

Pump Casing and Cover feature metal-to-metal fit with fully confined, controlled compression gasket to ensure proper sealing and alignment.

Motor Support head machined to accept NEMA P-Base and IEC motor designs.

Operating Parameters

- Flows to 500 m3/h (2200 gpm)

- Heads to 275 m (900 ft)

- Pressures to 40 bar (580 psi)

- Temperatures from -100°C (-148°F) to 250°C (480°F)

Pumps for CO2 Capture, Transportation and Storage

Flowserve Pumps for CO2 Capture, Transportation and Storage – Pre-Combustion, Post-Combustion, Pipeline, Injection

PVML Centrifugal Pumps User Instructions

Flowserve PVML Centrifugal Vertical In-line, Diffuser Design Centrifugal Pumps – User Instructions: Installation, Operation, Maintenance

BF and BFD Between Bearings, Axially Split Multistage Pumps

BF and BFD Between Bearings, Axially Split Multistage Pumps

| Brand: | Flowserve |

|---|---|

| Description: | The BF and BFD are horizontal, axially split case, multistage centrifugal pumps adhering to ISO 13709/API 610 (BB1 and BB3)… |

The BF and BFD are horizontal, axially split case, multistage centrifugal pumps adhering to ISO 13709/API 610 (BB1 and BB3) standards. Designed for medium to high flows, high heads and maximum efficiency, the single-suction BF and double-suction BFD are well suited for pipeline, refinery and waterflood services. Both configurations are available in 2-, 3- and 4-stage designs.

- Applications:

Crude, Product and CO2 Pipeline, Dewatering and Water Supply (mining), Distillation (oil and gas), Gas to Liquids, Heavy Oil, Oil Sands and Shale, Water Supply and Distribution (water) - Industries:

Oil and Gas, Mining, Water Resources - Standards:

API610

Suction and Discharge Nozzles are integrally cast with the lower casing, allowing disassembly and inspection of the rotating assembly without disturbing the piping.

Double or Staggered Single Volute Design balances radial loads on the shaft, minimizing shaft deflection.

Near-centerline Mounting of casing feet ensures optimal alignment and performance when operating at elevated temperatures.

Long-radius Crossovers minimize flow losses between stages, helping to enable high efficiencies.

Cap Nuts are arranged on the top half casing parting flange, allowing easy casing removal for rotor inspection and maintenance.

Replaceable Casing and Impeller Wear Rings control interstage leakage and provide hydraulic stability.

Operating Parameters

- Flows to 4300 m3/h (18 800 gpm)

- Heads to 2130 m (6000 ft)

- Pressures to 230 bar (3335 psi)

- Temperatures to 200°C (400°F)

Flowserve BF and BFD Between Bearings, Axially Split Multistage Pumps Bulletin

Flowserve BF and BFD Between Bearings, Axially Split Multistage Pumps Bulletin – ISO 13709 / API 610 (BB1 and BB3)

PVXM ISO 13709/API 610 (OH3) Vertical In-Line Overhung API Process Pump

PVXM ISO 13709/API 610 (OH3) Vertical In-Line Overhung API Process Pump

| Brand: | Flowserve |

|---|---|

| Description: | The Flowserve PVXM vertical process pump features a diffuser design and a rugged in-line bearing housing. Compliant with… |

The Flowserve PVXM vertical process pump features a diffuser design and a rugged in-line bearing housing. Compliant with the latest ISO 13709/API 610 and BS 4082R standards, the PVXM is a space-saving alternative to horizontal overhung process pumps in upstream and downstream services.

- Applications:

Gas Treating and Sulfur Recovery, Paper Stock, Water Supply and Treatment (oil and gas), Distillation (oil and gas), Acid Transfer, Crude, Product and CO2 Pipeline, Water Treatment - Industries:

Chemical Processing, Water Resources, Oil and Gas, General Industries - Standards:

API682, API610

Suction Box Design provides shockless impeller entry and optimized NPSHR.

Dynamically Balanced Impeller limits vibration and ensures smooth operation over wide flow range. A smooth, investment cast surface provides excellent hydraulic efficiency.

Pump Casing and Cover feature metal-to-metal fit with fully confined, controlled compression gasket to ensure proper sealing and alignment.

Performance Tuning capabilities include field hydraulic customization.

Operating Parameters

- Flows to 500 m3/h (2200 gpm)

- Heads to 275 m (900 ft)

- Pressures to 40 bar (600 psi)

- Temperatures from -100°C (-148°F) to 250°C (480°F)

Hydrocarbon Processing Pumps

Flowserve Pumps for Hydrocarbon Processing – Refining, Petrochemical Processing

Oil & Gas Pumps

Flowserve Pumps for Oil & Gas – Upstream and Pipeline – Offshore – Onshore – Synthetic Crude and LNG

PVXM API 610 / ISO 13709 (OH3) Bulletin

Flowserve PVXM API 610 / ISO 13709 (OH3) – Vertical In-line Diffuser Process Pump With Bearing Housing

PVXM Centrifugal Pumps User Instructions

Installation, Operation, Maintenance for PVXM Pumps

Pulley Blocks and Sheaves

Pulley Blocks and Sheaves

| Brand: | Flowserve |

|---|---|

| Description: | The lifting mechanism for the drill string utilizes multiple blocks and sheaves built to Flowserve specifications. Multiple… |

The lifting mechanism for the drill string utilizes multiple blocks and sheaves built to Flowserve specifications. Multiple sizes and load ratings are available to meet specific unit requirements.

- Applications:

Petroleum Production and Refining, Decoking - Industries:

Heavy Oil and Upgrading, Delayed Coking

Features and Benefits

The drill stem lift mechanism uses a four-part reeving system of high-strength cable and pulley blocks and sheaves. Both hanging block type pulleys and overhead supported sheaves can be provided. Attachment of blocks to the crosshead and tower structure is achieved through the use of hanger plates which are custom designed for individual applications.

The guide sheave or the crown sheave is available with an adaptation for the system to indicate “in-drum” tool position. This system is compromised of a NEMA 7 box, a local indicator mounted on the hoist console, special probes and drilling on the guide sheave.

Hydraulic Decoking System Equipment Bulletin

Flowserve Hydraulic Decoking System Equipment

Decoking System Equipment Innovation Poster

Flowserve Decoking Poster – Innovation from the Global Leader in Hydraulic Decoking (11? x 17?)

MVX Solids Handling, Wet Pit

MVX Solids Handling, Wet Pit

| Brand: | Flowserve |

|---|---|

| Description: | The Flowserve MVX is a rugged wet pit pump designed for use in solids handling applications and other wet pit services. Built… |

The Flowserve MVX is a rugged wet pit pump designed for use in solids handling applications and other wet pit services. Built and tested in accordance with Hydraulic Institute standards, the MVX non-clog pump boasts numerous reliability- and performance-enhancing benefits.

- Applications:

Coatings (pulp and paper), Dewatering and Water Supply (mining), Flood Control, Flue Gas Desulfurization, Ground Water Development and Irrigation, Sewage Collection and Treatment, Shipping, Waste Processing, Water Supply and Distribution (water) - Industries:

General Industries, Mining, Power Generation, Pulp and Paper, Water Resources, Chemical Processing

Multi-volute Design provides perfect balance of radial reactive forces for smooth performance.

Enclosed, Mixed Flow Impeller is designed with a minimum number of vanes and wide passageways to minimize clogging. Vane tips are rounded to prevent the accumulation of stringy materials at the impeller eye.

Smallest model passes spherical solids up to 76 mm (3 in) diameter; larger models pass spherical solids up to 152 mm (6 in) diameter.

Splitter Vanes guide solids and stringy materials around the pump’s enclosing tube and into the discharge without clogging.

Enclosed Lineshaft protects bearing surfaces from abrasives.

Available Vortex Suppressor ensures maximum hydraulic efficiency.

Operating Parameters

- Flows to 17 000 m3/h (75 000 gpm)

- Heads to 40 m (130 ft)

- Sizes 250 mm (10 in) to 1200 mm (48 in)

- Drivers to 95 kW (1250 hp)

Decoking Hose

Decoking Hose

Brand |

Description |

| Flowserve | Flowserve decoking hoses are engineered to withstand the challenging conditions of delayed coker units (DCU). These high-pressure hoses are resistant to oil and chemicals, and are equipped with abrasive-resistant outer covers and multiple layers of wire reinforcement, ensuring exceptional strength and long-lasting durability. |

Flowserve decoking hoses are designed for the harsh environment of the delayed coker. These high-pressure hoses are oil and chemical resistant and feature abrasive-resistant outer covers with multiple layers of wire reinforcement for strength and durability.

- Applications:

Decoking, Petroleum Production and Refining - Industries:

Delayed Coking, Heavy Oil and Upgrading

Features and Benefits

Flowserve decoking hoses are manufactured to specification with ANSI RTJ flanges in various sizes and pressure ratings at each end. The flanges are butt-welded to built-in steel couplings that are permanently bonded to the hose. A swivel flange is provided to enable easier installation of the hose by allowing the hose to freely rotate without disengaging the RTJ flange bolting.

The hoses are built to API 7K specifications. Factory certified visual and hydrostatic test reports with supporting graphs are furnished with each hose.

Flowserve DVSH Between Bearings Pump

Flowserve DVSH Between Bearings Pump

Brand |

Description |

| Flowserve | Designed for continuous operation in heavy duty pipeline services, the DVSH is a between bearings, axially split single stage pump. With more than 100 different hydraulics, the DVSH offers unmatched coverage for dependable operation with thousands of units deployed globally. |

Flowserve DVSH Between Bearings Pump

With tens of thousands of units in operation around the world, the DVSH is the undisputed between bearings, axially split, single stage pump of choice. Fully compliant with the latest ISO 13709/API 610 (BB1) standards, the DVSH is particularly well-suited for use in process charge, transfer and pipeline services where uncompromising reliability over wide flow ranges is of utmost importance.

Axially Split API Pump Applications:

Crude, Product and CO2 Pipeline, Nuclear Service, Dewatering and Water Supply (mining), Drilling and Production, LNG, Renewable Fuel Production, Water Supply and Distribution (water), Auxiliary Services (power), Distillation (oil and gas), FPSO, Auxiliary (chemical), Cooling Water (power), Gas Treating and Sulfur Recovery, Boiler Feed (pulp and paper), Gas to Liquids, Boiler Feed Booster, Heavy Oil, Oil Sands and Shale, Condensate Extraction, Offsites and Waste Treatment

- Industries:

Chemical Processing, Mining, Water Resources, Power Generation, Pulp and Paper, Oil and Gas - Standards:

API682, API610

Double Volute, Axially Split Casing Design minimizes hydraulic radial forces in any condition down to the minimum flow.

Suction and Discharge Nozzles are integrally cast in the lower casing half to permit pump disassembly without disturbing the piping.

Near Centerline Mounting provides superior pump alignment and performance at elevated temperatures.

Double Suction Impeller provides hydraulic axial balance and allows minimal NPSHr.

ISO 21049/API 682 Seal Chambers ensure ample flow around the seal faces and accommodate numerous seal designs.

Heavy-Duty Shaft Design ensures trouble-free operation below the first critical speed.

Standard Renewable Casing and Impeller Wear Rings provide hydraulic stability and high operating efficiency.

Flowserve DVSH Between Bearings Pump-Axially Split, API, Single Case Operating Parameters

- Flows to 12 000 m3/h (52 835 gpm)

- Heads to 565 m (1854 ft)

- Pressures to 150 bar (2175 psi)

- Temperatures to 200°C (400°F)

- Speeds to 6000 rpm

PHL ISO 13709/API 610 (OH2) Centerline Mounted Process Pump

PHL ISO 13709/API 610 (OH2) Centerline Mounted Process Pump

| Brand: | Flowserve |

|---|---|

| Description: | The Flowserve PHL-MAG is the magnetic drive configuration of the PHL horizontal, overhung impeller design. Hydraulics are… |

The Flowserve PHL-MAG is the magnetic drive configuration of the PHL horizontal, overhung impeller design. Hydraulics are custom-tuned for the actual duty point by employing innovative diffuser technology. The permanent magnet drive provides 100% leak-free operation and no risk of pumped liquid contamination.

- Applications:

Auxiliary Services (power), Crude, Product and CO2 Pipeline, Waste Treatment, Drilling and Production, Distillation (oil and gas) - Industries:

Oil and Gas, Water Resources, Power Generation - Standards:

API682, API610

Hydraulics Are Custom Tuned for the actual duty point by project-specific design of multi-channel diffuser.

Diffuser Tuning Maximizes Pump Efficiency, widens operational flow window, and minimizes radial loads at any flow.

Hastelloy C-276 Containment Shell hydrotested to 60 bar (900 psi).

Features:

- Product lubricated silicon carbide bearings

- Replaceable diffusers for future and different head flow duty

- Other configurations

- Top suction nozzle to reduce space requirements

- PHL (standard sealed)

Operating Parameters

- Pressures to 40 bar (600 psi)

- Temperatures to 200°C (400°F)

- Up to 110 kW (145 hp) motor size at 3000 rpm

- Up to 132 kW (175 hp) motor size at 3600 rpm

PHL Pump Bulletin

Flowserve PHL Pumps – ISO/13709/API 610 (OH2), Centerline Mounted, Diffuser Style, Overhung Process Pump

LC Chemical Slurry Pump

| Brand: | Flowserve |

|---|---|

| Description: | The LC chemical slurry pump is a horizontally orientated, frame-mounted, single-stage, end-suction configuration featuring a tangential discharge nozzle. It is designed to endure the demands of abrasive and corrosive applications. |

The LC chemical slurry pump is a horizontal, frame mounted, single stage, end suction design with a tangential discharge nozzle. It is engineered to withstand the rigor of applications that are both abrasive and corrosive.

- Applications:

Acid Transfer, Caustic and Chlor-alkali, Chemical and Liquor (pulp and paper), Dewatering and Water Supply (mining), Leaching Acid, Water Supply and Distribution (water), Plating, Galvanizing and Other Coatings, Polymers, Primary Processing (mining), Slurry Processing, Slurry Transfer (mining), OEM - Industries:

General Industries, Mining, Chemical Processing, Pulp and Paper, Water Resources, Primary Metals

Thick Wall Concentric Casing With Tangential Discharge is radially balanced and is free of cavities and obstructions that cause wear.

Balancing Counter Vanes Hydraulic Sealing limits internal recirculation and reduces seal chamber pressure. Mechanical seals with radial faces optional.

Rigid, One-Piece Bearing Frame is generously sized to handle belt loads and can be removed easily for maintenance. Allows ample access to seal chamber.

Two Angular Contact Outboard Bearings and a single inboard roller bearing mitigate axial and radial thrust.

Multiple impeller types and pump configurations are available to meet application and installation requirements.

Operating Parameters

• Flows to 8000 m3/h (35 200 gpm)

• Heads to 90 m (300 ft)

• Pressures to 25 bar (360 psi)

• Temperatures to 140°C (285°F)

• Specific gravities to 1.7

LC Slurry Pump Bulletin

Flowserve LC Chemical Slurry Pump Product Bulletin

LC, LCT and LCH Centrifugal Pumps User Instructions

Installation, Operation, and Maintenance instructions for Single-stage, single volute, axial suction and directional lateral discharge type centrifugal pumps.

MPT Self-Priming, Overhung, Solids Handling Pump

MPT Self-Priming, Overhung, Solids Handling Pump

| Brand: | Flowserve |

|---|---|

| Description: | Reflecting its commitment to making flue gas desulfurization (FGD) systems more effective, Flowserve developed the rubber… |

The Flowserve MPT is a self-priming, solids handling pump designed to provide reliable, peak performance and low cost in demanding services containing suspended solids. The MPT deftly handles dirty, gritty water as well as free-flowing slurries, sewage, sewage sludge and many trade effluents.

- Applications:

Descaling, Flue Gas Desulfurization, Construction, Slurry Transfer (mining), Ground Water Development and Irrigation, Shipping, Dewatering and Water Supply (mining) - Industries:

General Industries, Water Resources, Mining

Two-Vane, Semi-Open, Solids Handling Impeller has integral back pump-out vanes and is fully balanced. Impeller is threaded to shaft and spigotted for positive location.

External Impeller Adjustment via four adjustable bushings allows clearances to be accurately reset, thereby restoring performance.

Heavy-Duty Volute Casing designed for rugged, long-life service.

Abrasion-Resistant Mechanical Seal prevents contaminants from entering the seal chamber. Large oil-filled chamber for long seal life.

Operating Parameters

- Flows to 600 m3/h (2650 gpm)

- Heads to 35 m (115 ft)

- Temperatures to 75°C (165°F)

- Working pressures to 5 bar (72 psi)

- Sizes 50 to 200 mm (2 to 8 in)

- Solids to 75 mm (3 in) diameter

MPT Self-Priming, Solids-Handling Pump Poster

MPT Self-Priming, Solids-Handling Pump Poster

MPT Pump Maintenance Checklist

Flowserve MPT Self-Priming Solids-Handling Pump Maintenance Checklist

MNR and MND Overhung Absorber Recirculation Pumps

MNR and MND Overhung Absorber Recirculation Pumps

| Brand: | Flowserve |

|---|---|

| Description: | The Flowserve MP1 multiphase pump is engineered for the challenges of today’s industry. It is designed for high-viscosity,… |

Reflecting its commitment to making flue gas desulfurization (FGD) systems more effective, Flowserve developed the rubber lined MNR and metallic MND absorber recirculation pumps. Built upon the proven design and hydraulics of the Flowserve MN solids-handling pump, the MNR and MND pumps are renowned for their high efficiency and versatility.

- Applications:

Flue Gas Desulfurization, Slurry Processing, Shipping - Industries:

Chemical Processing, Power Generation, General Industries

High Efficiency Impeller is one piece design with no exposed threads. Mixed flow vane design is highly efficient at hydraulic conditions found in recirculation services. Multiple materials choices permit maximum wear life in corrosive and erosive environments.

Replaceable Casing Wear Ring extends casing life and is available in many corrosion and abrasion resistant materials.

Opposed Tapered Roller Bearings firmly support the shaft, virtually eliminate axial and radial thrust loads, and are designed for a minimum B10 life of 100 000 hours.

MNR’s Radially Split Casing provides access to the impeller. Tangential discharge provides unobstructed flow path and extends wear life.

MNR’s Removable One Piece Elastomeric Liner protects against wear and allows for both front and back pullout.

Features:

- Product flush slurry seal

- External end clearance adjustment

- Front and back pullout

- Optional vertical configuration

- Reduced shaft deflection

- Smaller footprint

- Reduced radial loads

- Easy retrofits

Operating Parameters

- Flows to 17 500 m3/h (77 000 gpm)

- Heads to 40 m (130 ft)

- Sizes 600 mm (24 in) to 1000 mm (40 in)

MNR MND Absorber Recirculation Pumps Bulletin

Flowserve MNR MND Absorber Recirculation Pumps

MP1 Multiphase Screw Pump

MP1 Multiphase Screw Pump

| Brand: | Flowserve |

|---|---|

| Description: | This ASME Section lll, Class 2 and 3 pump is designed for chemical and volume control system charge service with boiling… |

The Flowserve MP1 multiphase pump is engineered for the challenges of today’s industry. It is designed for high-viscosity, high flow, low NPSH applications. Highly reliable in tough services, the MP1 is able to handle slurries to 70% solids by weight and multiphase applications to 100% gas void fractions.

- Applications:

Crude, Product and CO2 Pipeline, Drilling and Production - Industries:

Oil and Gas

Double-Suction Design provides balanced hydraulic loads by channeling incoming flow to the screw inlets at each end of the pump.

External Bearings and AGMA 11 Timing Gears are in separate oil reservoirs to eliminate exposure to the pumped fluid.

Versatile ISO 21049/API 682 Seal Chamber readily accommodates multiple seal types and meets HSE regulations without modification.

Split Bearing Bracket Construction facilitates easy maintenance of individual bearings and mechanical seals.

Modular Non-Welded Casing is available in multiple standard and specialty alloys.

Nozzles integral to the outer casing insulate the inner casing from piping loads, helping to maintain a non-contacting shaft design.

Operating Parameters

- Flows to 1990 m3/h (8750 gpm)

- Pressure to 50 bar (720 psi)

- Temperatures to 450°C (850°F)

- Viscosities to 8000 cp

- Gas volume fractions from 0% to 100%

- Shaft tip speeds to 30 m/s (100 ft/s)

Oil & Gas Pumps

Flowserve Pumps for Oil & Gas – Upstream and Pipeline – Offshore – Onshore – Synthetic Crude and LNG

CAV Nuclear Pump

CAV Nuclear Pump

Brand |

Description |

| Flowserve | The Flowserve AFV axial flow suspended shaft vertical pump is a single-stage propeller type design. This family of pumps is engineered to meet the demanding requirements of nuclear power plant pumps, offering reliable performance and efficiency as part of the comprehensive Flowserve CAV Nuclear Pump line, tailored for nuclear industry solutions. |

Flowserve CAV Nuclear Pump

This ASME Section lll, Class 2 and 3 pump is designed for chemical and volume control system charge service with boiling water reactors (BWR), pressurized water reactors (PWR), and pressurized heavy-water reactors (PHWR).

- Applications:

Nuclear Service - Industries:

Power Generation - Standards:

Nuclear

Suction and Discharge connections meet AREVA piping requirements.

Outer Casing is designed for full working pressure and meets all pressure boundary requirements for pump equipment.

Inner Assembly has an internal crossover that reduces hydraulic thrust and increases bearing life.

Standard Cartridge Seal reduces maintenance time and man-rem exposure associated with change out.

Optional Bearing Housing mounted in the motor stand permits the use of standard electric motors without thrust bearings.

Four-piece spacer coupling allows maintenance to bearings and mechanical seal without removal of the electric motor.

Nuclear Power Plant Pumps Operating Parameters

- Flows to 60 m3/h (265 gpm)

- Heads to 2000 m (6560 ft)

- Pressures to 235 bar (3410 psi)

- Temperatures to 100°C (212°F)

- Speeds to 3600 rpm

Low-Head High-Flow Pump

The Low-Head High-Flow Pump suspended shaft vertical pump is a single stage Vertical Propeller Pump type design. This family of pumps is specifically designed for low head movement of water for a multitude of municipal, agricultural and industrial services.

- Applications:

Flood Control, Water Treatment, Shipping, Ground Water Development and Irrigation, Cooling Water (power), Dewatering and Water Supply (mining), Agriculture - Industries:

Mining, Water Resources, Power Generation, General Industries

Three- or Four-Vane Axial Flow Propeller is hydraulically balanced via pressure equalizing balance holes and a top propeller hub wear ring to reduced axial down thrust.