Centrifugal Plastic Pumps

Technical Characteristics I Technical Characteristics II Operation ManualBrochurePerformance Curves

- Viscosity: 200 cSt

- Capacity: up to 140 mc/h

- Delivery Head: up to 44 m

- Speed: 1450 / 3500 rpm

- Temperature: From -85°C to 90°C (higher temp. on request)

- Casing pressure: PN 6

- Flange connections: UNIVERSAL DESIGN ACC. TO DIN EN 1 092-2 / PN 10, ANSI B16.5 150 lbs.

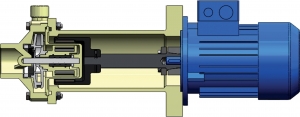

Pumps of the series C MAG-P are horizontal single-stage volute casing pumps with closed impeller. Close coupled pumps are furnished with standard motors. Leak-free back pull-out assemblies with magnetic drive meet the requirements with regard to job safety, operational reliability and environmental protection. Modular impeller allows for varying hydraulic performances.

Magnetic drive rear casing standard materials are PP glass fiber, or PVDF carbon fiber, other materials, available on request.

Simplicity constructive and high thickness of the casings, achieved by CNC machine from solid, give greater resistance to permeation and migration of corrosive, and permeating liquids are the features of this pump range.

Over-sized, high purity ceramic or silicon carbide thrust bearings and shaft. The program comprises 6 sizes, with a high interchangeability between the components of this pump series, and the C MAG-PL series, that allows important stock reductions. Standard, direct starting IEC or NEMA motors

Casing pressure:

Maximum 6 bar.

Note

For a correct evaluation: Casing pressure = inlet pressure + delivery head at minimum pump capacity.

Position of the ports

End suction port, top discharge port

Flanges / Threads:

The flanges are of universal design; correspond to DIN EN 1092-2 / PN 16, ANSI B16.5 150 lbs, other connections, available on request.

For the C MAG-P32 and C MAG-P40 threaded connections NPTF / BSPF are supplied.

For the C MAG-P32 and C MAG-P40 threaded connections NPTF / BSPF are supplied.

Bearings

PTFEC bearings, on high purity alumina (99, 7%) shaft are the standard configuration, lubricated by the pumped liquid. Available with dry running carbon bearings, or with alpha grade silicon carbide bearings, shaft and thrust bearings, full SIC.

Direction of rotation:

Clockwise, when looking from the pump end.

Motor

Electric motor, IEC type of construction IM B5 for close couple version, supplied with WCB foot mounted bracket.

C MAG-P32 and C MAG-P40 can be supplied in close couple version, with IM B3 B5 motor, and plastic bracket, NEMA motors C type available.

C MAG-P32 and C MAG-P40 can be supplied in close couple version, with IM B3 B5 motor, and plastic bracket, NEMA motors C type available.

Applications

C MAG-P pumps range meets the requirements on custom-built solutions in the process industry, in the following areas: Chemical and pharmaceutical, transfer of aggressive, highly corrosive liquids, paper, food processing, plant engineering and construction. For all industries that choose a pumping leak-free and low maintenance for use continuous (abandon of mechanical seal pumps).

Technical Characteristics I Technical Characteristics II Operation ManualBrochurePerformance Curves

Pump construction

Close-coupled drivers are conventional drivers mounted directly to pumps frame. No base, coupling or guards are required for this mounting style. Universal Flanges Connections that meet DIN PN16 and ANSI 150#.

Operating limits

– Max viscosity: 200 cSt

– Max system pressure: 5 bar

– Flow up: to 70 mc/h

– Head up: to 32 m

– Temperature range:

from 24 °F (-5 °C)

to +194 °F (+90 °C)

– Electric motors:

from 1,5 up to 9,2 kW

– Self priming up: to 4 m

– Available ATEX II – / 3G cbk II C T5

The separation of liquid chamber/ atmosphere by means of an isolation shell is the best solution to pump aggressive chemical, high purity liquids and liquids difficult to seal. The hermetic sealless is the best solution for the chemical and pharmaceutical industry. A wide range of pumps covers the different performances.

The simple construction combined with high thickness guarantees a long life against corrosion.

Pump casing shall be one single piece, achieved from solid bar, made of very high thickness PP and PVDF to have a good mechanical resistance and a guaranteed long life against the corrosion.

Epoxy primer and polyacrylic enamel water-based painting for the best quality resistance linked to the environmental respect

RWP QUICK CHANGE CARTRIDGE KIT

to guarantee an easy

and fast maintenance, materials: PP and PVDF.

The sealing system with O-Rings prevents from leaking in the atmosphere – different materials available:

– EPDM

– VITON®

– FEP

The rear shell is made of thermoplastic materials, as PP GFR or PVDF CFR with zero magnetic losses. Outside rear shell cover ellipsoidal profile made of fiber reinforced composite material.

High power synchronous magnetic coupling designed by our Technical Office and with magnetic elements mechanically locked.

Rare earth guarantees the magnetic-balancing to avoid the thrust bearing wear and the heat generation.

Field assembling of the product lubricated bearing arrangement does not require special tools.

The Shaft / Bearing materials are available in three different

configurations to provide the best solution for each application:

– PTFEC – ALLUMINA 99,7% (standard)

– CARBON – ALLUMINA 99,7%

– Silicon Carbide (SSIC) – Silicon Carbide (SSIC)

Technical Characteristics I Technical Characteristics II Operation ManualBrochurePerformance Curves

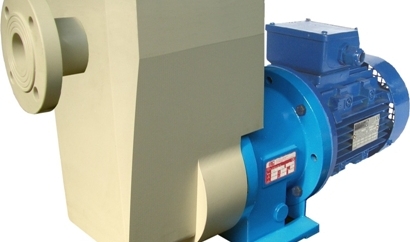

Pump construction and Operative limits

Close-coupled drivers are conventional drivers mounted directly to pumps frame. No base, coupling or guards are required for this mounting style.

Connection:

– Threaded BSP (GAS) & NPT.

– Max viscosity 200cSt

– Max system pressure 6 bar

– Flow up to 35 mc/h

– Head up to 23 m

– Temperature range:

from -4°F (-20°C)

to +176°F (+80°C)

– Electric motors:

from 0,12 up to 4 kW

Horizontal, sealless PP and PVDF centrifugal pump with permanent magnet drive system, no mechanical seal.The separation of liquid chamber/ atmosphere by means of an isolation shell is the best solution to pump aggressive chemical, high purity liquids and liquids difficult to seal.

The hermetic sealless is the best solution for the chemical and pharmaceutical industry.

A wide range of pumps covers the different performances.

The simple construction combined with high thickness at interesting prices.Making a comparison between this range of pumps and the other two M PUMPS series C MAG-P and C MAG-PL, the correct definition becomes few components (extremely easy maintenance), competitive prices, guaranteed chemical compatibility.Pump casing shall be one single piece, injection moulded designs, made of GFR PP and CFR PVDF.RWP QUICK CHANGE CARTRIDGE KIT

to guarantee an easy and fast maintenance, materials PP and PVDF.The sealing system with O-Rings prevents from leaking in the atmosphere.

Different materials available:

– EPDM

– VITON®The rear shell is made of thermoplastic materials, ellipsoidal profile, zero magnetic losses, GFR PP or GFR PVDF materials.High power synchronous magnetic coupling designed by our Technical Office and with magnetic elements mechanically locked.

– EPDM

– VITON®The rear shell is made of thermoplastic materials, ellipsoidal profile, zero magnetic losses, GFR PP or GFR PVDF materials.High power synchronous magnetic coupling designed by our Technical Office and with magnetic elements mechanically locked.

Rare earth guarantee the magnetic balancing to avoid the thrust bearings wear and the heat generation.

Field assembling of the product lubricated bearing arrangement does not require special tools.

The Shaft / Bearing materials are available in two different configurations to provide the best solution for each application:

Field assembling of the product lubricated bearing arrangement does not require special tools.

The Shaft / Bearing materials are available in two different configurations to provide the best solution for each application:

– PTFEC – ALLUMINA 99,7% (standard)

– CARBON – ALLUMINA 99,7%

Technical Characteristics I Technical Characteristics II Operation ManualBrochurePerformance Curves

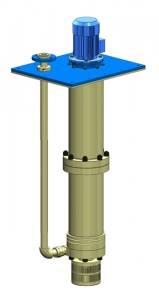

Operating limits

- Max viscosity: 200 cSt

- Flow up: to 140 mc/h

- Head up:to 44 m

- Temperature range: from -22 °F (-30 °C) to +194 °F (+90 °C)

- Electric motors: from 1,5 up to 18,5 kW

- Lenght up: to 7 m

The separation of liquid chamber/atmosphere by means of an isolation shell is the best solution to pump aggressive chemical, high purity liquids and liquids difficult to seal.

The hermetic sealless is the best solution for the chemical and pharmaceutical industry.

A wide range of pumps covers the different performances. The simple construction combined with an high thickness guarantees a long life against the corrosion.Pump casing shall be one single piece, achieved from solid bar, made of very high thickness PP and PVDF to have a good mechanical resistance and a guaranteed long life against the corrosion.

The sealing system with O-Rings prevents from leaking in the atmosphere.

The hermetic sealless is the best solution for the chemical and pharmaceutical industry.

A wide range of pumps covers the different performances. The simple construction combined with an high thickness guarantees a long life against the corrosion.Pump casing shall be one single piece, achieved from solid bar, made of very high thickness PP and PVDF to have a good mechanical resistance and a guaranteed long life against the corrosion.

The sealing system with O-Rings prevents from leaking in the atmosphere.

Different materials are available:

– EPDM

– VITON®

– EPDM

– VITON®

Epoxy primer and polyacrylic enamel water-based painting for the best quality resistance linked to the environmental respect.

Strong carbon Steel CNC machined construction, protected by an high tickness thermoplastic shell, to reach the best compromise between mechanical and corrosion resistance.ù

Special PVDF FCR screws for external parts in contact with the liquid. High thickness thermoplastic barrier to avoid any possibility of corrosion.

RWP QUICK CHANGE CARTRIDGE KIT

to guarantee an easy and fast maintenance, PP and PVDF materials.

– Standard version

– CFR version

– Standard version

– CFR version

Pump casing shall be one single piece, achieved from solid bar, made of very high thickness PP and PVDF to have a good mechanical resistance and a guaranteed long life against the corrosion.

Ball bearings sealed for life (Lh=30000 hours) to support the shaft line, smart additional modules that allowes arrive up to 7 m depth.

The rear shell is made of thermoplastic materials, as PP GFR or PVDF FCR with zero magnetic losses.

Outside rear shell cover ellipsoidal profile made of fiber reinforced.

Outside rear shell cover ellipsoidal profile made of fiber reinforced.

High power synchronous magnetic coupling designed by our Technical Office and with magnetic elements mechanically locked.

Rare earth guarantees the magnetic-balancing to avoid the thrust bearing wear and the heat generation.

Rare earth guarantees the magnetic-balancing to avoid the thrust bearing wear and the heat generation.

Field assembling of the product lubricated bearing arrangement does not require special tools.

The Shaft / Bearing materials are available in three different configurations to provide the best solution for each application:

– PTFEC – ALLUMINA 99,7% (standard)

– CARBON – ALLUMINA 99,7%

– Silicon Carbide (SSIC) – Silicon Carbide (SSIC)

None

None

Technical Characteristics I Technical Characteristics II Operation ManualBrochurePerformance Curves

Pump construction and Operating Limits

- -Close-coupled configuration allows conventional drivers to be mounted directly to pump frame. No base, coupling or guards are required for this mounting.

- Connections: Threaded BSP (GAS) & NPT.

- Max viscosity: 200cSt

- Max system pressure: 5 bar

- Flow up: to 30 mc/h

- Head up: to 24 m

- Temperature range: from -76 °F (-60 °C) to +194 °F (+90 °C)

- Electric motors: from 1,5 up to 7,5 kW

The separation of liquid chamber/ atmosphere by means of an isolation shell is the best solution to pump aggressive chemical, high purity liquids and liquids difficult to seal. The hermetic sealless is the best solution for the chemical and pharmaceutical industry.

A wide range of pumps covers the different performances.

Simple, robust construction, made out of few components, extremely easy maintenance, guaranteed chemical compatibility at competitive prices.

RWP QUICK CHANGE CARTRIDGE KIT

to guarantee an easy and fast maintenance, materials PP and PVDF.

Pump casing in one single piece, injection moulded designs, made of GFR PP and CFR PVDF.

Sealing system with O-Rings prevents from leaking to the atmosphere – different materials available:

– EPDM

– VITON®

Rear shell made of thermoplastic materials, ellipsoidal profi le, zero magnetic losses, GFR PP or CFR PVDF materials.

High power synchronous magnetic coupling designed by our Technical Office and with magnetic elements mechanically locked.

Rare earth guarantee magnetic-balancing to avoid thrust bearings wear and heat generation.

Field assembling of the product lubricated bearing arrangement does not require special tools.

The Shaft / Bearing materials are available in two different configurations to provide the best solution for each application:

– PTFEC – ALLUMINA 99,7% (standard)

– CARBON – ALLUMINA 99,7%

None