Alfa Laval Shutter Valve

Alfa laval’s shutter valves are suitable in applications with large products, high viscous or strict requirements minimizing pressure loss. The shutter valve range is designed for use in the food, chemical, pharmaceutical and other industries with high hygiene requirements.

Alfa Laval Valve Automations: Indication Unit, IndiTop, ThinkTop, ThinkTop Basic, ThinkTop D30, GreenTop

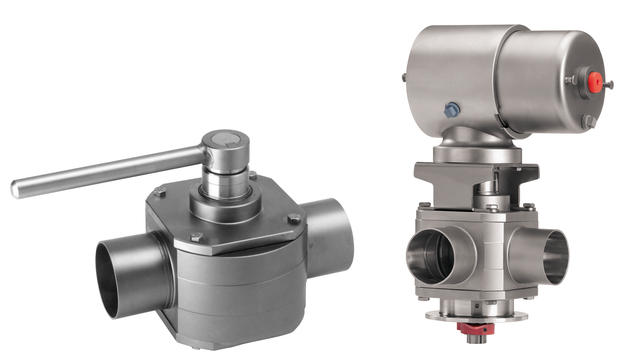

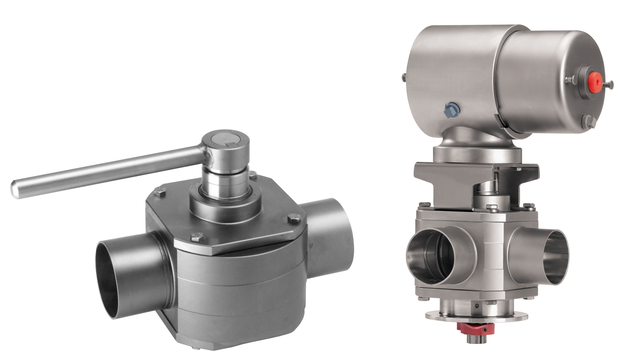

ALFA LAVAL KOLTEK SHUTTER VALVE

The Koltek shutter valve from Alfa Laval is a manually or pneumatically operated valve designed for use in the food, chemical, pharmaceutical, and other industries where sanitary designs are required. Specifically designed for difficult applications, Koltek shutter valves provide several functionality options and work for products with large particles, high viscosity, or where pressure loss must be minimized.

MODELS

- 2-Way

- 3-Way

- Manual

- Air Actuated

Related Industries:

Processed Foods, Home & Personal Care, Pharmaceutical, Biotech, Chemical

Application

MH Koltek valve is a manually or pneumatically operated valve, designed for use in the food, chemical, pharmaceutical and other industries where valves of sanitary design are needed.

Standard Design

The valve consist of a rigid body with an internal cylindrical bore and 2 or 3 ports for pipe connection. The two lids have guide rings for an internal shaft which supports and positions the shutter.

The stainless steel handle or the actuator is fitted to turn the shaft.

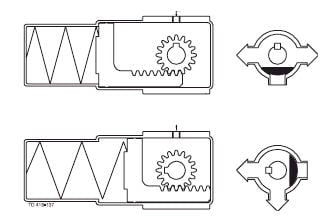

The actuator consists a system of cylinders and one or two main pistons interconnected with a toothed bar which interacts with a gear wheel on the valve shaft. The system is insensitive to pressure shocks in the valve.

The valve has welding ends as standard.

MH52 with handle

Working principle

A PTFE shutter is operated by means of a handle or an actuator. A spring system presses the shutter against the inside cylindrical surface of the valve body thus ensuring complete tightness.

The air actuated valve can be fitted with ThinkTop® or a laterally fitted indication unit for remote indication of the valve position. The manually operated valve can be fitted with laterally indication units (used for LKLA actuators). The actuator for the valve comes in two versions, single acting or double acting. The single acting actuator operates with one main piston whereas the double acting actuator operates with two main pistons.

Single acting actuator

WORKING PRINCIPLE

A PTFE shutter is operated by means of a handle or an actuator. A spring washer system presses the shutter against the internal cylindrical surface of the valve body, ensuring a tight seal.

The air-actuated valve can be fitted with top units or a laterally fitted indication unit for remote indication of the valve position. The manually operated valve can be fitted with laterally mounted indication units. The actuators are a rack and pinion design available in spring return or air-to-air versions. The spring return actuator operates with one main piston, while the air-to-air actuator operates with two.

STANDARD DESIGN

The valve consists of a rigid body with an internal cylindrical bore and two or three ports for pipe line connection. The two lids have guide rings or bearings for an internal shaft, which supports and positions the shutter. The stainless steel handle or actuator is fitted to turn the shaft.

The actuator consists of a system of cylinders and one or two main pistons interconnected with a toothed bar (rack and pinion), which interacts with a gear wheel on the valve shaft. The system is insensitive to pressure shocks in the valve.

Certain industries require disassembly and cleaning of the manually operated versions of the valve. Pneumatically operated versions of the valve do not need to be disassembled to ensure proper cleaning, if correctly controlled (pulsed) during the cleaning operation.

To achieve total drainability, the manual or pneumatically operated version of the valve should be installed in the piping system with at least one port in the vertical downward position.

MATERIALS

| Product Wetted Steel Parts | 316L |

| Finish | Polished |

| Seals | Shutter in PTFE |

| Seals (in valve) | EPDM rubber |

| Seals (in actuator) | Nitrile (NBR) |

TECHNICAL DATA

| Max Temperature | 230°F |

| Max Pressure Against Shutter | 44 psi |

| Max Pressure Behind Shutter | 145 psi |

| Air Pressure for Actuator | 116 psi (max) |

| Compressed Air Connection | R 1/8″ (BSP), internal thread |