Alfa Laval Sampling Valve

Alfa Laval sampling valves make it possible to obtain representative samples of food and beverage, personal care and biopharm products.

Alfa Laval Valve Automations: Indication Unit, IndiTop, ThinkTop, ThinkTop Basic, ThinkTop D30, GreenTop

Unique Sampling Valve

Unique Sampling Valve

Alfa Laval Unique sampling valves make it possible to obtain representative samples of food and beverage, personal care and biopharm products.These reliable single- and double-seat valves contribute to quality, and cost-effective sampling.

Related Industries:

Biotech and Pharmaceuticals, Energy and Utilities, Food and beverage, Home and Personal care

High operational reliability

Alfa Laval Unique single-seat and double-seat sampling valves meet the requirements for high quality product extraction in a variety of hygienic processes. Both provide high accuracy, exceptional reproducibility of sampling and excellent reliability.

Enhanced cleanability

All Unique sampling valves feature a valve body made of a single piece of stainless steel, providing smooth, crevice-free surfaces. Because no welding is required, the risk of pore formation and cracking in the welds and subsequent risk of bacterial build-up is eliminated.

Easy to operate and maintain

The customary, ergonomically designed handle provides exceptional control and convenience during operation. Replacing the membrane seal is straightforward; loosening the handle and lifting off the membrane is all that is required.

Unique sampling valve range

The Unique Sampling valve range comprises 4 valve configurations.

| |

Unique sampling valve – Single seatThe Unique single-seat sampling valves are ideal for use in various applications. This standard valve can easily be upgraded to a Unique double-seat sampling valve with a convenient, easy-to-use upgrade kit. |

|

Single seated pneumatic actuatorThe single seated sampling valve with the pneumatic actuator ensures opening and closing of the valve. With the pneumatic actuator remote sampling is an option and for indication of the valves positioning an indication proximity switch, can be added. |

| |

Unique sampling valve – Double seatSpecially engineered, the Unique double-seat sampling valves are an excellent choice for use in applications where a higher cleanability is required. Patented technology ensures sterilization of the valve seat and channels, thus ensuring sampling precision and accuracy and guaranteeing representative sampling. |

|

Double seated pneumatic actuatorThe double seated sampling valve with the pneumatic actuator ensures total sterilization of the entire valve seat and channels. With the pneumatic actuator remote sampling is an option and for indication of the valves positioning an indication proximity switch, can be added. |

Warranty

Alfa Laval provides a three-year warranty for all non-wearing parts,provided genuine parts are used.

Certification, specification and standards

All Unique sampling valves are designed, tested and approved according to EHEDG guidelines and certified to carry the 3-A symbol. All machined components are made of 3.1b certified AISI 316L. For more information, please consult the documentation provided.

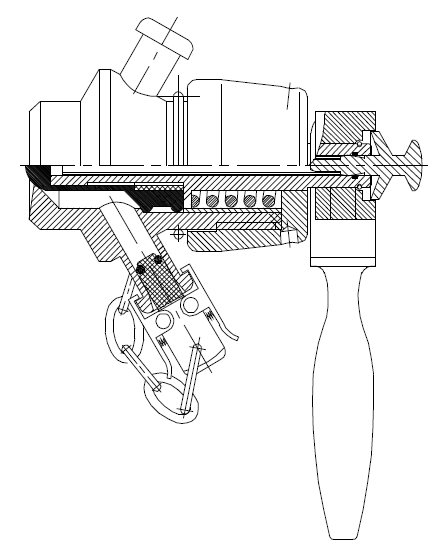

Construction

Unique sampling valves consist of a valve body, an actuator and membrane seal. The rubber membrane seal is placed on the stem of

the actuator and functions as a stretchable plug. The valve bodies and

actuators are interchangeable.

Product range

Unique sampling valves are available as single- and double-seat

sampling valves with working pressures up to 6 bar and maximum

temperatures of 130 °C.

|

Valve type |

Size |

Product type |

Max. Particle size |

|

Single-seat Double-seat |

Type 4 |

Low viscosity |

Up to 2,5 mm |

|

Single-seat Double-seat |

Type 10 |

Medium viscosity |

Up to 7 mm |

|

Single-seat Double-seat |

Type 25 |

High viscosity |

Up to 20 mm |

Sampling accessories

Operating principles

Unique single-seat sampling valves

Designed for standard hygienic sampling, the single-seat sampling

valve has two positions: open and closed. It can easily be upgraded to a

double-seat valve by replacing the handle or actuator with an upgrade

kit.

Open position for sampling: To begin the sampling process, rotate the

handle in a counter-clockwise direction to open the valve, if using an

manual valve. If using a actuator, open the valve by activating the actuator. This retracts the valve stem and the membrane and enables the product to flow freely through the open valve.

Closed position for sterilization: To stop the sampling process, rotate

the handle in a clockwise direction to close the valve, if using a manual

valve or shut the air connection, if using a pneumatic actuator.

This shuts off the flow and makes the channel in between the connecting hoses available for sterilization. If steam is used for Sterilization-in-Place, Alfa Laval recommends the use of an optional pressure relief valve on the outlet.

A new level of accuracy with patented new technology

The design of single-seat technology poses challenges for complete

sterilization. In closed position, the membrane seal comes into contact

with the valve seat. These points of contact are virtually impossible to

clean due to tight surface compression and may therefore accumulate

product residue and microorganisms. For that extra level of security to

ensure a more representative sample, Alfa Laval recommends double seat technology.

Unique double-seat sampling valves

Designed for truly sterile sampling, the double-seat sampling valve has three positions: open, closed and sterilization.

Open position:

To begin the sampling process,

Manual valve: rotate the handle in a counter-clockwise direction to open the valve.

Pneumatic valve: supply air to the open connection.

This retracts the valve stem and membrane seal and enables the product to flow freely through the open valve.

Closed position:

To stop the sampling process:

Manual valve: Rotate the handle in a clockwise direction.

Pneumatic valve: Shut off the supplied air to the open connection.

Sterilization position:

To set the valve in sterilization position,

Manual valve: rotate the handle clockwise to the steam position.

Pneumatic valve: apply air to the steam connection.

This extends the valve heads inner spindle into the inner seat and stop product flow in the valve port. At the same time the valve heads outer spindle retracts and lifts the membrane seal away from its normal seat. Now it is possible to access the hard-to-reach areas on the seat surface, ensuring thorough sterilization and making the Unique double-seat sampling valve a solid and reliable choice to achieve 100% representative sampling.

Instruction Manual – Unique Sampling Valve – Type P – Pneumatic Operated –

EN Instruction Manual – Unique Sampling Valve – type M – manually operated –

EN Instruction Manual – Unique Sampling Valve – Accessories – Quick Connection –

EN Instruction Manual – Unique Sampling Valve – Accessories – Pressure Relief Valves – EN

Scandi Brew (SB) Membrane Sample Valve

Scandi Brew (SB) Membrane Sample Valve

The Alfa Laval Scandi Brew Membrane Sample Valve provides a compact and cost-effective way to obtain bulk or aseptic samples of brewery, food, dairy and beverage products, including highly viscous products, such as harvest yeast.

Related Industries:

Food Processing, Dairy Processing, Beverage Processing

High sampling reliability

The valve meets the requirements for high-quality product extraction in various hygienic processes with minimal risk of contamination. High accuracy, exceptional repeatability and excellent reliability are hallmarks of the valve.

Versatile hygienic design

Made of a single piece of stainless steel, valve body features smooth, crevice-free surfaces. Because no welding is required, the risk of pore formation and cracking in the welds and subsequent risk of bacterial build-up is eliminated. This highly versatile hygienic valve is available in several different designs to ensure sample reliability and safety for a broad range of applications.

Enhanced valve cleanability

Designed to help ensure effective sterilization before and after each sample, these valves are sterilized in place with alcohol or steam. This helps ensure a truly representative sample every time.

Product Benefits

- Low upfront investment costs

- Superior hygiene

- Compact size

Construction

The valve consists of a valve body, actuator and membrane seal, which is placed on the stem of the actuator and works as a stretchable plug. The valve is available in three different actuator designs:

- Manual – For manual activation

- Manual + Micro Port – For manual activation or sampling using a hypodermic needle to penetrate the membrane for sample taking.

- Manual + Pneumatic – For manual or pneumatic activation when the valve is connected to pipes for automatic sampling. The valve is then supplied with pipe outlet connections.

Operating principle

To take a sample, rotate the handle in a clockwise direction to open the valve. This retracts the membrane allowing the liquid to pass through the valve into the sample container. To close the valve for sterilization before and after taking each sample, rotate the handle in a counter-clockwise direction to channel between the valve ports is open for sterilization.

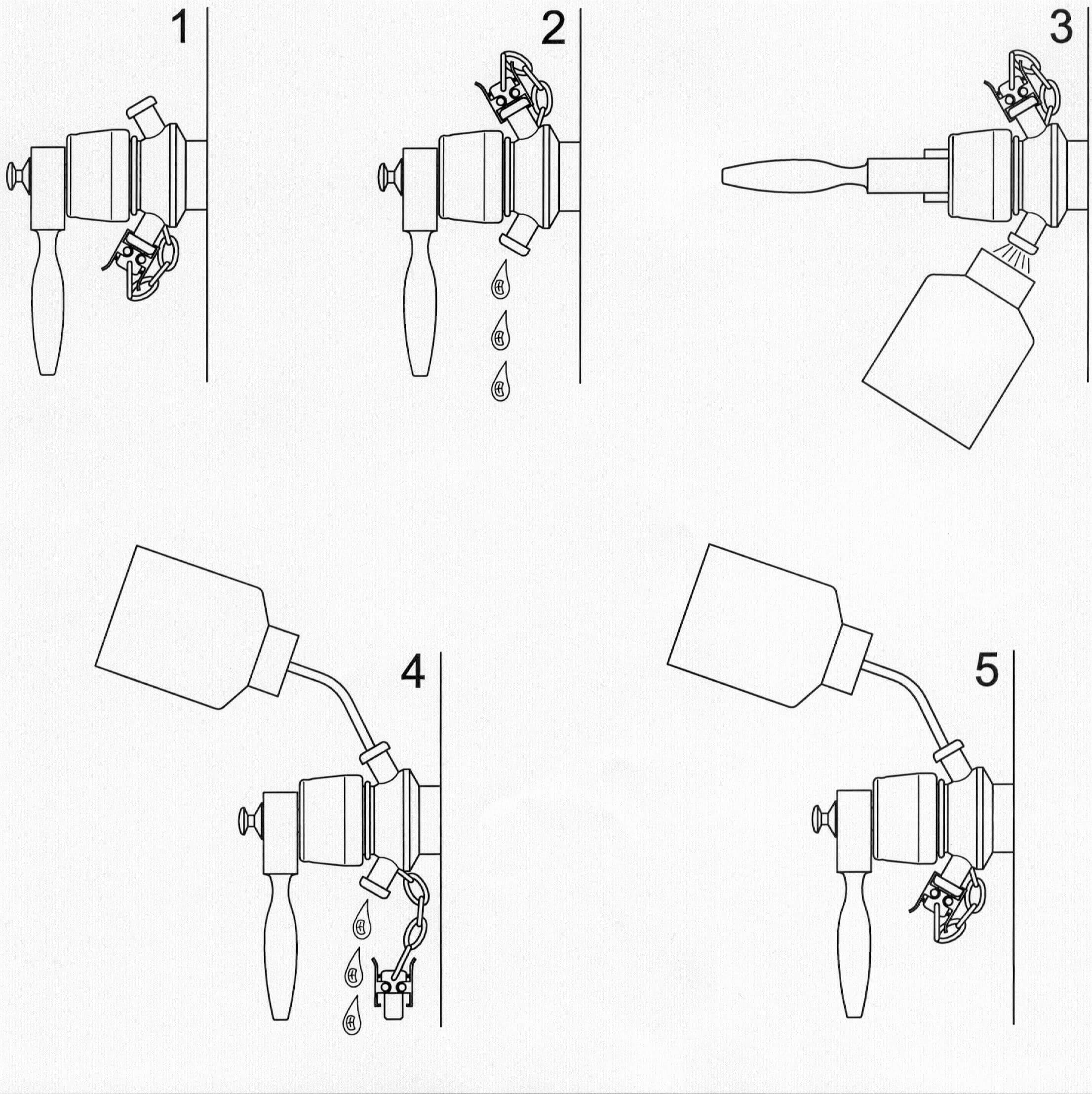

Function and cleaning

1 Alcohol sealed valve

2 Alcohol is drained and the valve can be steam sterilized

3 Sample is taken

4 Valve is flushed with water/alcohol

5 Valve is sealed with alcohol

Type W – Harvest Yeast Sample Valve

The valve is available in three different mounting designs:

Concept

The membrane sample valve is used for sampling from tanks and

pipework under sterile conditions. The valve is sterilized in place with

alcohol or steam. Membrane sealing directly against product ensures

representative sampling, giving repeatable results safe to secondary

contamination.

Working principle

Before opening the valve, the closing cap should be placed on upper

hose piece. When handle is placed into horizontal position the required

flow through the lower outlet is obtained. When handle is back into

vertical position the valve is closed and the handle can be removed if

required. Aseptic sampling is possible from a special valve type with

micro port. By removing the red closing cap, a hypodermic needle

can be inserted through a central channel into the membrane and the

aseptic sampling takes place with the valve in closed position. After

sampling the valve should be flushed with water or alcohol. Sterilization

has to take place by means of alcohol or steam.

Standard Design

All types are available for manual or pneumatic operation. The two

outlets are hose pieces designed as clip-on. The standard valve is

equipped with one clip-on closing cap.

TECHNICAL DATA

Product pressure: . . . . . . . . . Max. 6 bar as standard.

10 bar is available on request

PHYSICAL DATA

Pressure

Valve body: . . . . . . . . . . . . .1.4404 (AISI 316L)

Other metallic parts: . . . . . . .1.4307 (AISI 304L)

Membrane: . . . . . . . . . . . . .Silicone. EPDM on request

Options

• Handle for operating the valve

• Assembling tool

• Membrane remover

• Proximity switch for indication of open/closed valve position

• Sampling coil with clip-on

• Isobaric hand bottling device with clip-on

• Hypodermic needle

• Silicone hose with clip-on

Related Industries:

Food Processing, Beverage Processing

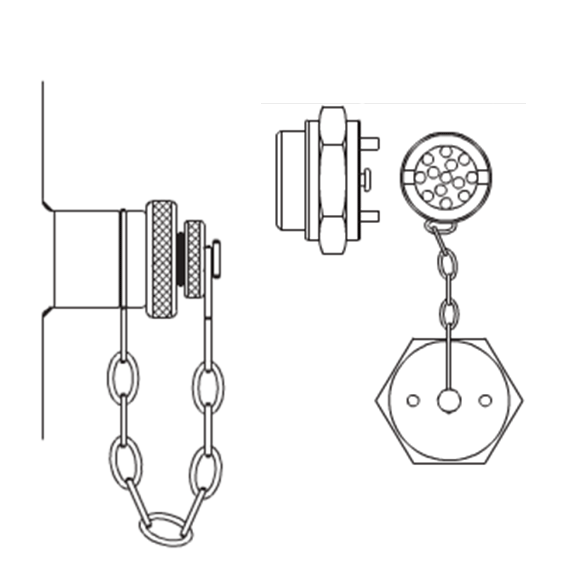

Aseptic sampling for microbiological control

To help ensure food and beverage safety, the sample port features a straightforward hygienic design with minimal components makes collecting samples mid-stream easy, convenient and accurate.

Versatile mounting

Direct mounting on the tank wall, pipe wall, or extruded pipe ends in either a vertical and horizontal position makes the port versatile and suitable for a broad range of applications and provides the flexibility needed to meet your sampling requirements.

Easy to clean

Hygienic design ensures optimum hygiene for representative sampling. When the port is located on the tank wall or pipe wall, the plug end that is flush with the wall is automatically cleaned during the routine Cleaning-in-Place (CIP) cycle. To minimize the risk of contamination, it is easy to sterilize the rest of the plug with alcohol before sampling.

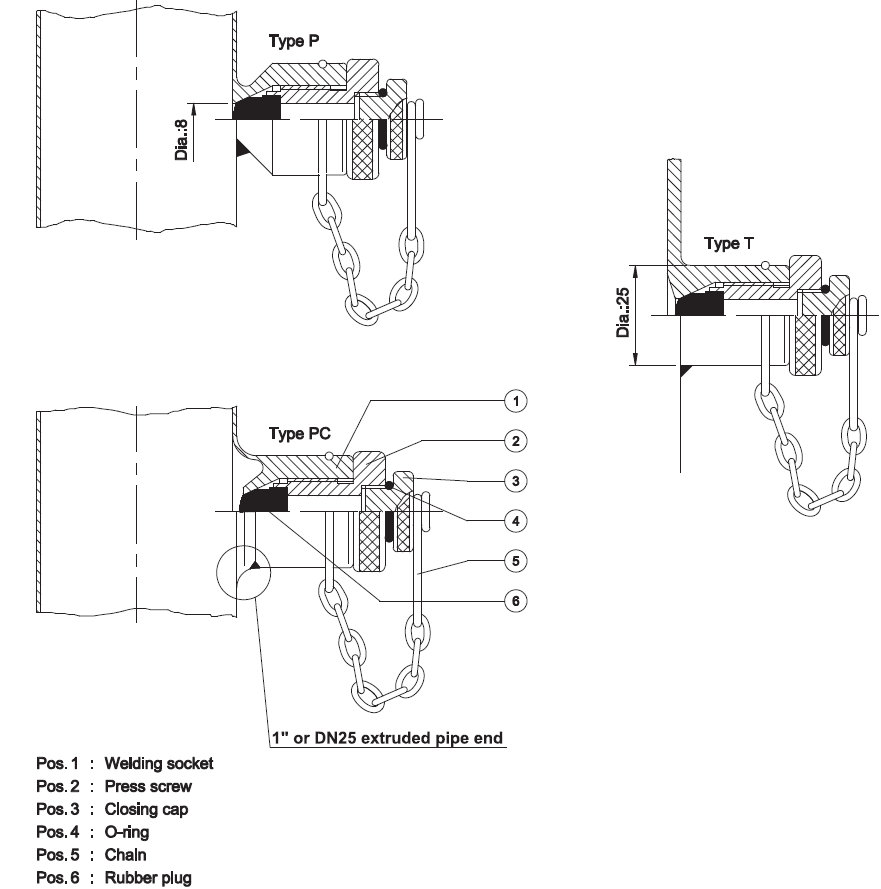

Construction

The sample port consists of a housing made as a socket for direct welding into the tank wall or pipework, a rubber plug which is positioned by a press screw, an o-ring, chain and a closing cap. These different types of sockets are mounted:

- Socket, Type T, is welded into a 25-mm diameter hole in a tank wall

- Socket, Type P, is welded onto a pipe wall and, thereafter, an 8-mm hole is drilled

- Socket, Type PC, is available for welding onto extruded pipe ends equal to 1” as well as DN25

Operating principle

To take a sample, simply unscrew the closing cap and insert a one-mm hypodermic needle through the rubber plug.

A30 SAMPLE VALVE

A30 SAMPLE VALVE

ABS offers Alfa Laval’s A30 push-button sample cock valve which can mount directly to a ferrule on the side of a tank or vessel. The sample is taken with a simple press of the spring-return manual actuator.

The A30 valve is available with Tri-Clamp® or bevel seat connections.

Related Industries:

Processed Foods, Beverages, Brewery, Home & Personal Care, Chemical

FEATURES

- Typically mounted on tanks

- Operated by depressing spring-loaded stem

- Tri-Clamp or bevel seat connections

- 1½ and 2 inch connection sizes

MATERIALS

| Product Wetted Steel Parts | 316L |

| Stem and Seat | Buna (standard), SFY |

| Other Steel Parts | 304 |

660 SERIES FRACTIONAL VALVES

660 SERIES FRACTIONAL VALVES

Alfa Laval’s 660 Series fractional valves from ABS offer convenient manual operation in a fractional size valve. Alfa Laval designed these valves for applications which require a secure, sanitary or sterile environment.

Tri-Clamp® or hose barb outlets make this valve versatile for standard shutoff or sampling purposes.

Related Industries:

Processed Foods, Beverages, Brewery, Home & Personal Care, Chemical

FEATURES

- Available with ½ inch Tri-Clamp x ¼ inch hose barb or ½ inch Tri-Clamp x ½ inch Tri-Clamp

- Modified designs available from ABS to fit special applications

- Standard handle is knurled polyethylene; bronze handle available for higher pressure/heat applications

- Teflon plug with o-ring, optional electropolished ID

WORKING PRINCIPLE

The 660 valve is operated by means of a manual handle, which raises and lowers the PTFE valve plug.

FEATURES

- Available with ½ inch Tri-Clamp x ¼ inch hose barb or ½ inch Tri-Clamp x ½ inch Tri-Clamp

- Modified designs available from ABS to fit special applications

- Standard handle is knurled polyethylene; bronze handle available for higher pressure/heat applications

- Teflon plug with o-ring, optional electropolished ID

DIMENSIONS

MATERIALS

| Product Wetted Steel Parts | 316L |

| Other Steel Parts | 304 |

| Plug | PTFE |

| O-ring | SFY |

| Handle | UHMV (standard) Bronze (optional) |

TECHNICAL DATA

| Max Temperature (UHMW polyethylene handle) | 150°F |

| Max Temperature (bronze handle) | 250°F |

| Max Pressure (UHMW polyethylene handle) | 150 psi |

| Max Pressure (nominal) | 230 psi at 72°F 100 psi at 250°F |