Worthington

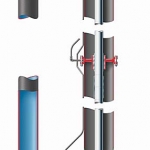

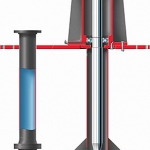

The Flowserve QL vertical, double suction pump has a single impeller and true twin volute design that produces more head and can operate at higher speeds than conventional, multistaged vertical turbine models. It can be used in all wet pit applications and virtually eliminates erosion and corrosion of the shaft, bearings and all internal components. Double Suction (First Stage) Impeller features large passageways and produces balanced hydraulic thrust for a stable performance curve with low shut-off pressure. The double-suction design on multistage pumps permits higher head and orating speed than vertical turbine models while maintaining excellent suction attributes. Heavy Walled, Twin Volute Casing with robust transition diffuser moves liquid from casing to column through large waterways at low liquid velocity, minimizing corrosion, erosion and radial loads on bearings. Suction Bells efficiently direct liquid into the impeller inlets with minimum resistance. Bottom Liquid End Bearing is sealed for life with grease. Optional Impeller Wear Rings enable restoration of original clearances for increased efficiency. Operating Parameters Flowserve QLC and QLQC Series Double-Casing, Double-Suction, Twin-Volute Turbine Pumps Poster Flowserve QL Series Pumps – Vertical, Double-Suction Twin-Volute Turbine Pumps – QL – QLQ – QLC – QLQC Installation, Operation, and Maintenance for Single stage, double suction, vertical wet pit and canned centrifugal pumps QL and QLQ Vertical Double Suction, Twin Volute Wet Pit

QL and QLQ Vertical Double Suction, Twin Volute Wet Pit

Brand:

Worthington

Description:

The Flowserve QL vertical, double suction pump has a single impeller and true twin volute design that produces more head…

Water Supply and Distribution (water), Descaling, Water and CO2 Injection, Agriculture, Flood Control, Cooling Water (metals), Sewage Collection and Treatment, Dewatering and Water Supply (mining), Fire Protection, Water Treatment, Ground Water Development and Irrigation, Leaching Acid, Cooling Water (power)

General Industries, Mining, Water Resources, Power Generation, Primary Metals, Oil and Gas

QLC and QLQC Series Pumps Poster

QL Series Pumps Bulletin

QL and QLC Centrifugal Pumps User Instructions

Designed for water treatment, digester operations, flue gas desulfurization, waste processing, sewage collection and treatment, shipping, groundwater development, and irrigation. Chemical Processing, General Industries, Water Resources, Pulp and Paper, Power Generation Flexible Design includes horizontal and vertical models, variety of nozzle position options and direct or independent motor mounting. Minimal Shaft Deflection with oversized shaft and reduced overhang eliminates shaft failure and increases packing or seal life. Hardened Chrome Steel wear rings and shaft sleeve extend pump life. Stuffing Box readily accommodates packing or mechanical seals, per customer preference.

Worthington MF and MFV Solids Handling Pump

Brand

Description

Worthington

The Flowserve MF and MFV is an end-suction, side discharge, mixed flow, non-clog pump. This pump is designed specifically for reliability, low cost and long life in demanding sewage handling services or where suspended solids are of particular concern.

Worthington MF and MFV Solids Handling Pump

Best pump for sewage handling applications:

Industries:

Features:

Operating Parameters

The type MJ hard metal, vertical lineshaft pump is designed to handle services containing coarse solids in suspension and is suitable for a broad range of wet and dry pit applications. Hard Metal Casing made from abrasion and corrosion resistant high chrome iron incorporates integrally cast straightening vanes in the suction nozzle to reduce pipe swirl and extend impeller life. Closed Impeller has pump-out vanes on front and rear shroud to reduce stuffing box pressure and suction recirculation, as well as to balance axial hydraulic loads. Standard Packing Type Stuffing Box is protected by replaceable wear plate and is drilled and tapped for L5 and 2L3 lantern ring positions. Provided with full and low flow flush connections. Optional 316 SS, Alloy 20 or Alloy C-276 materials. Cast Iron Lower Bearing Housing is fitted with a rubber or urethane fluted bearing, which is contained in a rigid stainless steel shell and lubricated from an external clear liquid source. Features: Installation, Operation, & Maintenance Instructions for Vertical Wet Pit MJ Overhung, Vertical Lineshaft, Hard Metal Slurry Pump

MJ Overhung, Vertical Lineshaft, Hard Metal Slurry Pump

Brand:

Worthington

Description:

The type MJ hard metal, vertical lineshaft pump is designed to handle services containing coarse solids in suspension and…

Dry Pit, Water Treatment, Wet Pit, Mining, Slurries, Pulp and Paper, Mineral Processing, Sump Service

Wastewater Collection and Treatment, Water Treatment, Slurry Transfer, Slurry Processing

MJ Slurry Pump User Instructions

The type MJC hard metal slurry pump is a true stiff-shaft cantilever design, without bottom bearings and requiring no flushing water. The MJC is particularly well suited for applications in which flushing liquids are not available or cannot be tolerated. Hard Metal Casing made from abrasion and corrosion resistant high chrome iron incorporates integrally cast straightening vanes in the suction nozzle to reduce pipe swirl and extend impeller life. Closed Impeller includes pump-out vanes on front and rear shroud to reduce stuffing box pressure and suction recirculation as well as balance axial hydraulic loads. Standard Packing Type Stuffing Box is protected by replaceable wear plate and is drilled and tapped for L5 and 2L3 lantern ring positions. Provided with full and low flow flush connections. Optional 316 SS, Alloy 20 or Alloy C-276 materials. Features: Flowserve Type M Hard Metal Abrasive Slurry Pump MJC Overhung, Vertical Cantilever, Rubber Lined Slurry Pump

MJC Overhung, Vertical Cantilever, Rubber Lined Slurry Pump

Brand:

Worthington

Description:

The type MJC hard metal slurry pump is a true stiff-shaft cantilever design, without bottom bearings and requiring no flushing…

Sump Service, Slurries, Pulp and Paper, Wet Pit, Mining, Dry Pit, Mineral Processing

Wastewater Collection and Treatment, Water Treatment, Slurry Transfer, Slurry Processing

Type M Hard Metal Abrasive Slurry Pump Bulletin

<span=”color: #000000;”>[/su_tab][/su_tabs]