PolyChem S-Series Fluoropolymer Lined Overhung ASME Chemical Process Pump

PolyChem S-Series Fluoropolymer Lined Overhung ASME Chemical Process Pump

PolyChem S-Series Fluoropolymer Lined Overhung ASME Chemical Process Pump

| Brand: | Durco |

|---|---|

| Description: |

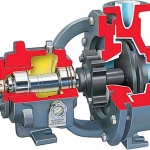

The Flowserve PolyChem S-Series ASME pumps are non-metallic, conventionally sealed chemical process pumps designed to meet ASME B73.1 dimensional standards. These pumps are constructed with fluoropolymer (PTFE/PFA) linings that offer superior chemical resistance, making them ideal for transferring aggressive, corrosive, or hazardous fluids in a wide range of industrial applications. Built with an overhung, end-suction configuration, the PolyChem S-Series delivers excellent hydraulic performance, extended service life, and reduced maintenance in demanding environments. Its non-metallic wetted components eliminate the risk of corrosion and metal contamination, perfect for acid handling, caustic service, chlor-alkali processes and other chemical operations where metallic pumps are unsuitable. The S-Series offers full compliance with ASME B73.1 specifications and provides safe, reliable operation across chemical manufacturing, semiconductor production, water treatment and more. |

PolyChem S-Series Fluoropolymer Lined Overhung ASME Chemical Process Pump Applications

Water Treatment, Volatile Organic Compounds, Agriculture, Waste Processing, Automotive, Auxiliary (chemical), Caustic and Chlor-alkali, Construction, Desalination, Electronics, Food Processing, OEM, Pharmaceuticals, Plating, Galvanizing and Other Coatings, Polymers, Renewable Fuel Production, Shipping, Solvents, Acid Transfer

- Industries:

Chemical Processing, Water Resources, Primary Metals, General Industries - Standards:

ISO, ASME (ANSI)

PFA Lined Wet End is globally preferred for its superior corrosion resistance and temperature allowance.

Rugged Metal Armor meets material specifications of ASTM A395.

Mark 3A Power End provides industry-leading features of the Mark 3 pump including ANSI 3A power end.

Exclusive Oversized FM Seal Chamber with flow modifiers extends mechanical seal life and reduces costs.

Readily Available Economical Seal Selections provide maximum flexibility.

Operating Parameters

- Flows to 420 m3/h (1850 gpm)

- Heads to 145 m (480 ft)

- Pressures to 17 bar (250 psi)

- Temperatures from -30°C (-20°F) to 150°C (300°F)

Transfer corrosive and hazardous fluids with confidence using the PolyChem S-Series ASME pump. Contact us today to discuss materials, specs and chemical compatibility.