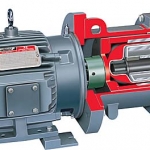

PolyChem M-Series Fluoropolymer Lined, Magnetic Drive, Overhung ASME Chemical Process Pump

PolyChem M-Series Fluoropolymer Lined, Magnetic Drive, Overhung ASME Chemical Process Pump

PolyChem M-Series Fluoropolymer Lined, Magnetic Drive, Overhung ASME Chemical Process Pump

| Brand: | Durco |

|---|---|

| Description: |

The Flowserve PolyChem M-Series ASME pumps are non-metallic, magnetically driven chemical process pumps designed to meet ASME B73.1 dimensional standards. Featuring a fluoropolymer-lined interior (PTFE or PFA) and a sealless magnetic drive design, the M-Series eliminates mechanical seals to provide leak-free, low-maintenance performance in corrosive and hazardous chemical applications. This overhung, end-suction pump configuration ensures high reliability and extended service life when handling aggressive, acidic, or toxic fluids. The mag drive design ensures full containment of process media, making the pump ideal for applications where zero emissions and operator safety are critical. The PolyChem M-Series ASME pump is widely used in chemical manufacturing, chlor-alkali systems, pharmaceutical production, semiconductor processing, and other environments that demand non-metallic, corrosion-resistant, and ANSI-compliant fluid handling. |

PolyChem M-Series Fluoropolymer Lined, Magnetic Drive, Overhung ASME Chemical Process Pump Applications:

Water Treatment, Pharmaceuticals, Plating, Galvanizing and Other Coatings, Polymers, Renewable Fuel Production, Shipping, Solvents, Volatile Organic Compounds, Agriculture, Waste Processing, Automotive, Auxiliary (chemical), Caustic and Chlor-alkali, Construction, Desalination, Electronics, Food Processing, OEM, Acid Transfer

- Industries:

Chemical Processing, Water Resources, Primary Metals, General Industries - Standards:

ISO, ASME (ANSI)

PFA Lined Wet End is globally preferred for its superior corrosion resistance and temperature allowance.

Rugged Metal Armor meets material specifications of ASTM A395.

Separate Inner Magnet and Impeller Components significantly reduce impeller replacement cost compared with integral inner magnet/impeller designs.

Rotating Shaft Design eliminates need for shaft support obstructions in the casing inlet.

Rugged Silicon Carbide Bearings offer superior wear resistance and chemical inertness.

Operating parameters

- Flows to 135 m3/h (600 gpm)

- Heads to 145 m (480 ft)

- Pressures to 17 bar (250 psi)

- Temperatures from -30°C (-20°F) to 150°C (300°F)

Flowserve PolyChem M-Series Pumps – Exploded Views

Ensure leak-free, corrosion-resistant performance with the PolyChem M-Series ASME Magnetic Drive Pump. Contact us today for material compatibility and application support.