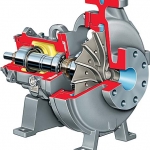

Mark 3 Lo-Flo Overhung Chemical Process Pump

Mark 3 Lo-Flo Overhung Chemical Process Pump

Mark 3 Lo-Flo Overhung Chemical Process Pump

| Brand: | Durco |

|---|---|

| Description: |

The Durco Mark 3 Lo-Flo pump is designed to improve pump reliability and performance in low-flow, high-head applications. As part of the Durco Mark 3 ANSI pump family, it features a robust overhung design optimized for precise chemical dosing, sampling, and transfer where traditional pumps are oversized or inefficient. Engineered by Flowserve, the Mark 3 Lo-Flo delivers stable operation, reduced vibration, and extended seal and bearing life, even at low capacity. This makes it the ideal solution for chemical processing, pharmaceuticals, petrochemicals and other industries requiring accurate and reliable fluid handling at reduced flow rates. Compliant with ASME (ANSI) B73.1 standards, the Mark 3 Lo-Flo ensures dimensional interchangeability and is built with corrosion-resistant materials for handling aggressive, toxic or temperature-sensitive fluids. |

Mark 3 Lo-Flo Overhung Chemical Process Pump Applications:

Coatings (pulp and paper), Acid Transfer, Construction, Water Treatment, Cooling Water, Electronics, FPSO, Food Processing, Solvents, HVAC, Leaching Acid, Polymers, Nuclear Service, OEM, Agriculture, Pharmaceuticals, Automotive, Plating, Galvanizing and Other Coatings, Auxiliary (chemical), Renewable Fuel Production, Caustic and Chlor-alkali, Auxiliary Services (power), Slurry Processing, Bleach Chemical (pulp and paper), Volatile Organic Compounds, Chemical and Liquor (pulp and paper), Water Supply and Distribution (water), Water Supply and Treatment (oil and gas)

- Industries:

Power Generation, Primary Metals, Pulp and Paper, Oil and Gas, Chemical Processing, General Industries, Mining, Water Resources - Standards:

ASME (ANSI)

Radial Vane Impeller provides improved performance over a broader application range.

Circular Concentric Casing reduces radial loads and vibration and extends bearing and seal life.

SealSentry Seal Chambers extend seal life and provide advanced self-flushing ability.

External Micrometer Impeller Adjustment accurately sets impeller clearance in 20 seconds, in the shop or the field.

Metal-to-Metal Construction assures a true running and concentric shaft, extending bearing and mechanical seal life.

Large Shaft and Bearing Components extend bearing life and reduce shaft deflection and vibration.

Features:

- Offered in a wide range of metallurgy

- Radial vane impeller

- Minimal thrust loads

- Reduced NPSH requirements

- Low seal chamber pressures

- Longer seal and bearing life

- ANSI 3A Power End

- Certified clean rooom assembly

- Inpro/Seal’s VBX isolators

- Magnetic drain plug

- Synthetic oil bath, oil mist, shielded, grease-lube

Operating Parameters

- Flows to 50 m3/h (220 gpm)

- Heads to 300 m (1000 ft)

- Pressures to 30 bar (450 psi)

- Temperatures from -75°C (-100°F) to 370°C (700°F)

Mark 3 Group 4 User Instructions

Mark 3 High Silicon Iron Pumps User Instructions

Durco Mark 3 Sealed Metallic Pumps User Instructions

Optimize your low-flow chemical transfer with the Durco Mark 3 Lo-Flo Pump, engineered for precision and reliability. Contact us today to explore materials and configurations.