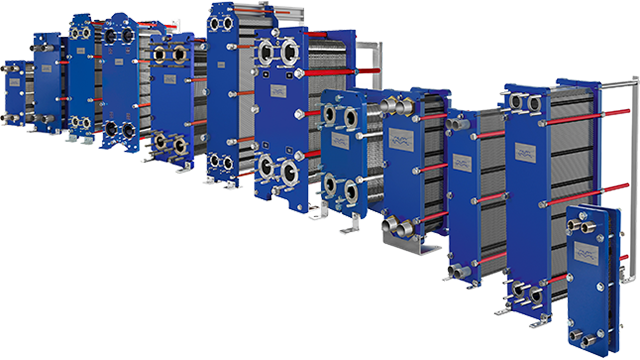

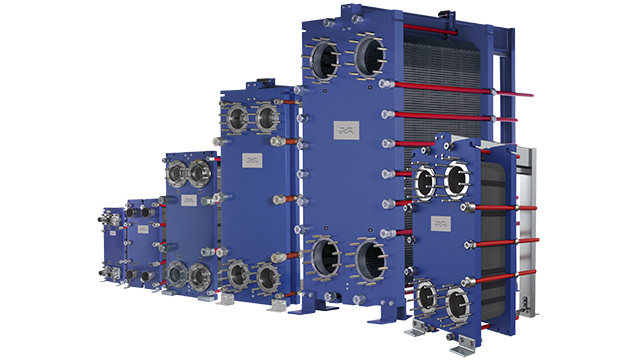

Alfa Laval Gasketed Plate Heat Exchanger

Part of a broad range of gasketed plate heat exchangers

AlfaVap is a tailor-made, rising film plate surface evaporator.

Industrial line is an extremely versatile range of heat exchangers for use in all types of industries.

Industrial semi-welded line is used when gaskets are not suitable for one of the media and when higher design pressures are needed.

WideGap is a heat exchanger used for applications involving fibrous liquids, highly viscous fluids, and fluids containing coarse particles.

Diabon® is a graphite plate-and-frame heat exchanger used for tough corrosive media.

AlfaQ™ is an AHRI performance certified gasketed plate-and-frame heat exchanger.

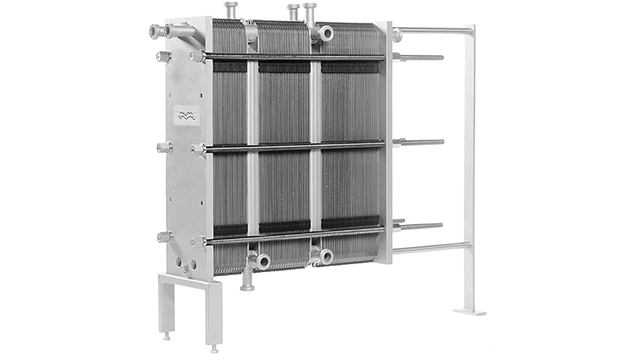

Alfa Laval Baseline Heat Exchanger

Alfa Laval Baseline Heat Exchanger

ABS offers Alfa Laval’s BaseLine Series heat exchangers. The BaseLine Series is the standard range of gasketed plate-and-frame heat exchangers used in hygienic applications. With its cost-effective frame design, this heat exchanger is a competitive choice for process and utility duties.

Made of solid stainless steel, Alfa Laval BaseLine heat exchangers can be use in the cooling and heating of applications such dairy, food, brewery, beverage, and viscous products. For more demanding hygienic applications, the Alfa Laval FrontLine range is the preferred selection. All models meet 3-A sanitary requirements.

MODELS

- Base-3

- Base-6

- Base-10

- Base-11

Related Industries:

Processed Foods, High-Acid Foods, Dairy, Beverages, Brewery, Home & Personal Care, Pharmaceutical, Biotech, Chemical

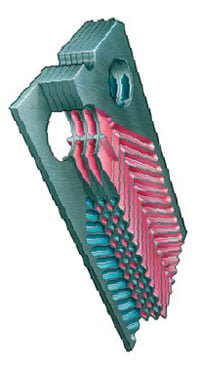

The heat transfer area of a gasketed plate-and-frame heat exchanger consists of a series of corrugated plates, assembled between the frame and pressure plates, which retain the design pressure. The sealing between the plates is made of gaskets. For the highest thermal performance and to enable a very close temperature approach, fluids normally run counter-currently through the heat exchanger.

BaseLine is available with various pressing depths and angles of the chevron pattern and various shapes of the corrugation which are carefully designed and selected to achieve optimal performance. The chocolate pattern distribution is a design feature that ensures fluids are evenly distributed across the entire plate. The result is that the entire heat transfer surface is fully utilized and stagnant zones that can result in fouling are avoided.

High flow turbulence between plates results in higher heat transfer; however, the consequence is pressure drop. Our thermal design engineers will help you design and select the model and configuration that is suitable for your application needs while delivering maximum thermal performance and minimizing pressure drop.

APPLICATION

Working at pressure up to 145 psi, Alfa Laval’s Baseline Series handles not only heating and cooling, but also pasteurization at low flow rates. These heat exchangers can be use in the cooling and heating of applications such dairy, brewery, beverage, and viscous products.

The Baseline Series heat exchanger is a competitive choice for hygienic processes and utility applications, such as simple pasteurization, raw milk cooling, media heating/cooling, and CIP heating. For more demanding hygienic applications the Alfa Laval FrontLine Series is the preferred selection.

WORKING PRINCIPLE

The plate heat exchanger consists of a pack of corrugated metal plates with portholes for the passage of two fluids between which heat transfer will take place. The plate pack is assembled between a frame plate and a pressure plate and compressed by tightening bolts. The plates are fitted with a gasket that seals the channel and directs the fluids into alternate channels. The number of plates are determined by the flow rate, physical properties of the fluids, pressure drop, and temperature program. The plate corrugations promote fluid turbulence and support the plates against differential pressure.

FRAME DESIGN

The plates and the pressure plate are suspended from an upper carrying bar and positioned with a lower guiding bar, both of which are fixed to the support column. On the largest type, some tightening bolts are equipped with ball bearing washers in order to facilitate opening and closing of the unit. The frame is designed for mounting on a floor only. Standard feet are fixed. One unit can contain several heat exchangers, separated by connection plates with interchangeable connections. (Not valid for Base-3 model.)

PLATE DESIGN

The corrugation of the plates provides a passage between the plates, supports each plate against the adjacent one and enhances the turbulence, resulting in efficient heat transfer. Corner ports and gaskets are arranged so that the two media flow through alternate channels. BaseLine is available in two different plate types: Chevron and Gemini.

The chevron pattern allows for maximum strength at high working pressures. Different chevron designs are available, in order to obtain optimal high heat transfer and low pressure drop. A unique distribution area provides an even flow over the plate surface. The plates are reversible and have parallel flow, which means only one type of plate is needed.

The Gemini double wall consists of two plates pressed together. This prevents cross contamination between fluids in case of leakage through the plates. The Alfa Laval hanging system enables easy handling of the plates in the frame and together with the corner guiding a strong plate pack.

MATERIALS

| Frame | Solid stainless steel |

| Pressure Plate | Solid stainless steel |

| Wetted Parts | Acid-proof stainless steel |

| Movable Nuts | Chromium-plated brass |

| Plate Materials | 316 stainless steel, titanium, SMO |

| Gasket | Nitrile-FDA, EPDM or EPDM-FDA (glue-free, clip-on gaskets) |

Meets all hygienic heating and cooling requirements

Alfa Laval BaseLine, with design pressure up to 10 bar (145 psi), meets all the requirements for pasteurization and other heating and cooling duties in hygienic applications.

Efficient design

Alfa Laval BaseLine uses FDA-compliant glue-free gaskets and is easy to open for inspection and cleaning or to clean by means of Cleaning-In-Place (CIP). The plate configuration is flexible with many options. In case the process parameters change, plates are conveniently replaced, added or removed.

Plate types for different hygienic needs

BaseLine is available with two different plate types:

- Chevron type plate pattern is used in a wide range of industries. This ensures good distribution of the product as well as high thermal efficiency.

- Gemini double wall consists of two plates pressed together. It prevents cross contamination between fluids in case of leakage through the plates.

The competitive choice

BaseLine is a competitive choice for hygienic processes and utility applications in dairy, food, and beverage industries. Examples of applications are:

- Simple pasteurization

- Raw milk cooling

- Utility media heating/cooling

- Cleaning-In-Place (CIP) heating

Alfa Laval FrontLine is recommended for more heat sensitive products or for products containing pulp and fibres.

Peace of mind

Alfa Laval global service network is never far away.

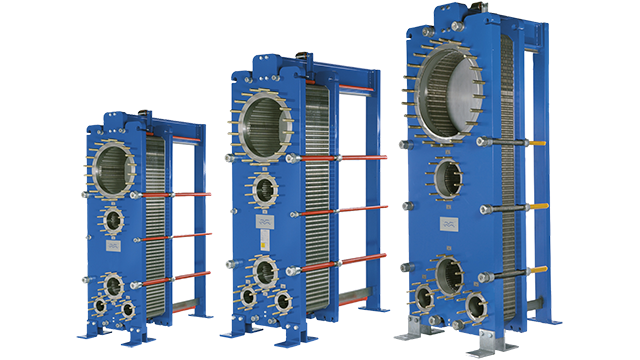

Alfa Laval M series Heat Exchanger

Alfa Laval M series Heat Exchanger

ABS offers Alfa Laval’s M Series plate heat exchangers as an efficient solution for general heating and cooling duties in hygienic applications. This range of heat exchangers is used in the same hygienic applications as the BaseLine range, but the M Series is selected when higher design pressure or extra-long plate packs are required.

M series are standard heat exchangers used in dairy, food, beverage, and other hygienic applications. They are competitive choices for hygienic processes and utility applications.

MODELS

- M3

- M6

- M10

- M15

Related Industries:

Processed Foods, High-Acid Foods, Dairy, Beverages, Brewery, Home & Personal Care, Pharmaceutical, Biotech, Chemical

Meets all hygienic heating and cooling requirements

Alfa Laval M line meets all requirements for pasteurization and other heating and cooling duties in hygienic applications.

Efficient design

Alfa Laval M line uses FDA-compliant glue-free gaskets and is easy to open for inspection and cleaning or to clean by means of Cleaning-In-Place (CIP). The plate configuration is flexible which means adding or removing plates is easy if process parameters change.

Plate types for different hygienic needs

M line is available with two different plate types:

- Chevron type plate pattern is used in a wide range of industries. This ensures good distribution of the product as well as high thermal efficiency.

- Gemini double wall consists of two plates pressed together. It prevents cross contamination between fluids in case of leakage through the plates.

The competitive choice

M line is in a competitive choice for hygienic processes and utility applications in dairy, food, and beverage industries. Examples of applications are:

- Simple pasteurization

- Raw milk cooling

- Utility media heating/cooling

- Cleaning-In-Place (CIP) heating

Alfa Laval FrontLine is recommended for more heat sensitive products or for products containing pulp and fibres.

Peace of mind

Alfa Laval global service network is never far away.

The heat transfer area of a gasketed plate-and-frame heat exchanger consists of a series of corrugated plates, assembled between the frame and pressure plates, which retain the design pressure. The sealing between the plates is made of gaskets. For the highest thermal performance and to enable a very close temperature approach, fluids normally run counter-currently through the heat exchanger.

M line is available with various pressing depths and angles of the chevron pattern and various shapes of the corrugation which are carefully designed and selected to achieve optimal performance. The chocolate pattern distribution area is a design feature that ensures fluids are evenly distributed across the entire plate. The result is that the entire heat transfer surface is fully utilized and stagnant zones that can result in fouling are avoided.

High flow turbulence between plates results in higher heat transfer; however, the consequence is pressure drop. Our thermal design engineers will help you design and select the model and configuration that is suitable for your application needs while delivering maximum thermal performance and minimizing pressure drop.

APPLICATION

An Alfa Laval M Series plate heat exchanger is an efficient solution for general heating and cooling duties in hygienic applications. In addition, the series is a perfect alternative for heating and cooling service media, including portable water, glycol, and chilled water tempering.

MATERIALS

| M3 | M6 | M10 | M15 | |

| Frame plate | Mild steel, epoxy painted | Mild steel, epoxy painted | Mild steel, epoxy painted | Mild steel, epoxy painted |

| Ports | 316, Titanium** | 316, Titanium** | 316, Titanium** | 316, Titanium |

| Plates | 304, 316, Titanium | 304, 316, Titanium | 304, 316, Titanium, Alloy 20/18/6 | 304, 316, Titanium, C-276, 254 SMO |

| Gaskets | Nitrile, EPDM, HeatSeal F* | Nitrile, EPDM, HeatSeal F* | Nitrile, EPDM, HeatSeal F*, HNBR*, EPDMF*, Viton® G* | Nitrile, EPDM, AL-EPDM, Nitrile hydrogenated, Viton G |

*Available only with specific plate types within the models

**Studded flange-style ports available in carbon steel with optional liners

WORKING PRINCIPLE

Channels are formed between the plates, and the corner ports are arranged so that the two media flow through alternate channels. The heat is transferred through the plate between the channels, and complete counter-current flow is created for highest possible efficiency. The corrugation of the plates provides the passage between the plates, supports each plate against the adjacent one, and enhances the turbulence to bring you efficient heat transfer.

STANDARD DESIGN

The plate heat exchanger consists of a pack of corrugated metal plates with portholes for the passage of the two fluids between which heat transfer will take place.

The plate pack is assembled between a fixed-frame plate and a movable pressure plate and compressed by tightening bolts. The plates are fitted with a gasket that seals the interplate channel and directs the fluids into alternate channels. The number of plates is determined by the flow rate, physical properties of the fluids, pressure drop and temperature program.

The plate corrugations promote fluid turbulence and support the plates against differential pressure. The plate and the pressure plate are fixed between the upper bar and lower bar, both of which are fixed to a support column.

Connections are located in the frame plate or, if either or both fluids make more than a single pass within the unit, in the frame and pressure plates.

Alfa Laval ClipLine Heat Exchanger

Alfa Laval ClipLine Heat Exchanger

Alfa Laval ClipLine range is used in the same hygienic applications as the FrontLine range, but ClipLine is used for smaller duties. ClipLine and FrontLine are premium ranges of heat exchangers used in dairy, food, beverage and other hygienic applications requiring gentle product treatment, long operating times or superior cleanability.

The Clip plate has a chevron type of plate pattern designed for hygienic conditions. The entry points, the distribution area and the shape and pressing depth of the plate pattern give optimal performance.

Related Industries:

Processed Foods, High-Acid Foods, Dairy, Beverages, Brewery, Home & Personal Care, Pharmaceutical, Biotech, Chemical

Efficient design

Alfa Laval ClipLine has a flexible design with tailor-made plates for demanding hygienic applications. It is particularly useful for small duties or tests in small-scale laboratory rigs. The plate pattern and the pressing depth are designed for gentle, uniform heat transfer for sensitive dairy, food and beverage products. The glue-free gaskets are made with FDA-compliant materials which are easy to maintain and have a long service life.

The frame is available for multi-section applications and is easy to disassemble for inspection, cleaning, and service. The connection plate corners are interchangeable and the heat transfer plates can easily be added or removed. This makes the ClipLine quick and easy to modify in the event that process conditions change.

Interchangeable corner

Plate for hygienic needs

ClipLine is equipped with the Clip plate, which is designed for sensitive hygienic applications and uncompromising cleanliness.

- Clip plate has a chevron plate pattern designed for hygienic conditions. The entry points, the distribution area, and the shape and depth of the pressed plate pattern allow for optimal performance.

ClipLine’s plate pattern and pressing depth are designed for gentle, uniform heat treatment of sensitive dairy, food, and beverage products. Examples of application uses are:

- Pasteurization of yoghurt and ice cream

- Pasteurization of cloudy fruit juice concentrate

- Heating and cooling of products with low viscosity

Alfa Laval BaseLine is recommended for less demanding hygienic applications.

Peace of mind

Alfa Laval global service network is never far away.

ClipLine’s plates are specifically designed for hygienic needs. The plate pattern, pressing depth, and the shape of the corrugation are all carefully designed and selected to achieve optimal performance. The chocolate pattern distribution area ensures that the fluids are evenly distributed across the entire plate to avoid stagnant zones that can result in fouling.

High flow turbulence between plates results in higher heat transfer; however, the consequence is pressure drop. Our thermal design engineers will help you design and select the model and configuration that is suitable for your application needs while delivering maximum thermal performance and minimizing pressure drop.

Applications

- Biotech and Pharmaceutical

- Food and Beverages

- Home and Personal care

Benefits

- Superior hygienic safety – plates designed for food applications

- Gentle treatment of sensitive products

- Uncompromising cleanliness

- Flexible configuration – possible to rebuild the heat exchanger

Features

Every detail is carefully designed to ensure the highest hygienic standards, gentle product treatment and efficient cleaning. Selection of available features:

- Clip-on gasket

- Leak chamber

- Fixed bolt head

- Key hole bolt opening

- Interchangeable corners

Extending performance with Alfa Laval 360° Service Portfolio

Our extensive services ensure top performance from your Alfa Laval equipment throughout its life cycle. The availability of parts and our team’s commitment and expertise bring you peace of mind.

Start-up

- Installation

- Installation Supervision

- Commissioning

Support

- Exclusive Stock

- Technical Documentation

- Telephone Support

- Training

- Troubleshooting

Maintenance

- Cleaning Services

- Reconditioning

- Repair

- Service Tools

- Spare Parts

Improvements

- Equipment Upgrades

- Redesign

- Replacement and Retrofit

Monitoring

- Condition Audit

- Performance Audit

ALFA LAVAL FRONTLINE HEAT EXCHANGER

ALFA LAVAL FRONTLINE HEAT EXCHANGER

FrontLine is a top-of-the-line series of plate heat exchangers. Able to meet the highest demands on hygienic control, it features a superior and flexible design that allows easy handling and modification.

Among the main applications for FrontLine are dairy pasteurization, yogurt cooling, UHT treatment and work with heat-sensitive products. FrontLine frames can be supplied in stainless steel and silver-coated versions, and the plates are available in alternative materials for challenging food-processing tasks.

MODELS

- Front-6

- Front-8

- Front-10

- Front-15

- Widestream®

- Gemini

Related Industries:

Processed Foods, High-Acid Foods, Dairy, Beverages, Brewery, Home & Personal Care, Pharmaceutical, Biotech, Chemical

Efficient design

Alfa Laval FrontLine allows a flexible design with plates tailor-made for demanding hygienic applications. The plate pattern and the pressing depth are designed for gentle, uniform heat transfer for sensitive dairy, food and beverage products. The glue-free gaskets are made with FDA-compliant materials which are easy to maintain and have a long service life.

The frame is available for multi-section applications and is easy to disassemble for inspection, cleaning, and service. The connection plate corners are interchangeable and the heat transfer plates can easily be added or removed. This makes the FrontLine quick and easy to modify in the event that process conditions change.

Interchangeable corner

Plate types for different hygienic needs

FrontLine is available with 3 different types of plates, all of which are designed for sensitive, hygienic applications and uncompromising cleanliness.

- Clip plate – The Clip plate has a chevron plate pattern designed for hygienic conditions. The entry points, the distribution area, and the shape and depth of the pressed plate pattern allow for optimal performance.

- Clip plate Gemini double wall – The Clip plate Gemini double wall consist of two plates pressed together.This prevents cross contamination between fluids in case of leakage through the plates.

- Clip plate WideStream – The Clip plate WideStream has a wider plate pattern with fewer contact points which makes it ideal for products containing pulp or fibres.

FrontLine’s plate pattern and pressing depth are designed for gentle, uniform heat treatment of sensitive dairy, food and beverage products. Examples of applications are:

- Pasteurization of yoghurt, ice cream, and beer

- Pasteurization of fruit juice with fibres

- Heating and cooling of viscous products

Alfa Laval BaseLine is recommended for less demanding hygienic applications.

Automatic model for easy use in pasteurization with high throughput

Alfa Laval’s FrontLine Automatic is an extended version that has a motor and a PLC based control system for automatic opening and closing of the heat exchanger. This is suitable for larger units in dairy pasteurization with high throughput where there is requirement for frequent inspection and cleaning.

Peace of mind

Alfa Laval global service network is never far away.

How it works

The heat transfer area of a gasketed plate-and-frame heat exchanger consists of a series of corrugated plates, assembled between the frame and pressure plates, which retain the design pressure. The sealing between the plates is made of gaskets. For the highest thermal performance and to enable a very close temperature approach, fluids normally run counter-currently through the heat exchanger.

FrontLine is available with different plate configurations which are designed for hygienic needs. The pressing depth and the shape of the corrugation are all carefully designed and selected to achieve optimal performance.

The chocolate pattern distribution area ensures that the fluids are evenly distributed across the entire plate to avoid stagnant zones that can result in fouling. High flow turbulence between plates results in higher heat transfer; however, the consequence is pressure drop. Our thermal design engineers will help you design and select the model and configuration that is suitable for your application needs while delivering maximum thermal performance and minimizing pressure drop.

APPLICATION

The Alfa Laval FrontLine Series is designed to meet the highest demands on hygienic control. It features flexible design that allows for easy handling and modification. The plate pattern and the pressing depth are designed for gentle, uniform heat transfer for sensitive dairy, food, and beverage products. The glue-free gaskets are made with FDA-compliant materials that are easy to maintain and have a long service life. The frame is available for multi-section applications and is easy to disassemble for inspection, cleaning, and service. The connection plate corners are interchangeable and the heat transfer plates can easily be added or removed, for easy modification as your needs change.

Among the main applications for FrontLine are dairy pasteurization, yogurt cooling, UHT treatment, and other heat-sensitive products. FrontLine frames can be supplied in stainless steel and silver-coated versions, and the CIP plates are available in alternative materials for challenging food-processing tasks. The series can handle the general cooling/heating requirements of the food, dairy, brewery, beverage, and pharmaceutical industries.

MATERIALS

| Frame | Solid, cladded stainless steel, surface coated |

| Pressure Plate | Solid, cladded stainless steel, surface coated |

| Wetted Parts | Acid-proof stainless steel |

| Movable Nuts | Chromium-plated brass |

| Other Surfaces | Various grades of stainless steel |

| Plate Types | Front 6, Front 8, Front 10, Front 15, Widestream, Gemini |

| Plate Materials | 316 stainless steel, titanium, SMO |

| Gasket | Nitrile-FDA, EPDM, EPDM-FDA (glue-free, clip-on gaskets) |

WORKING PRINCIPLE

A plate heat exchanger consists of a pack of corrugated metal plates with port holes for the passage of two fluids between which heat transfer will take place. The plate pack is assembled between a fixed frame plate and a movable pressure plate and compressed by tightening bolts. The plates are fitted with a gasket that seals the inter-plate channel and directs the fluids into alternate channels. The number of plates is determined by the flow rate, physical properties of the fluids, and the temperature program. Connections may be located in frame plate and pressure plate.

STANDARD DESIGN

Frame

The plates and the pressure plate are suspended from an upper carrying bar and positioned with a lower guiding bar, both of which are fixed to the support column. The tightening bolts are equipped with ball bearing washers in order to facilitate opening and closing of the unit. The frame and support column have adjustable feet. One unit may contain several heat exchangers, separated by connection plates with interchangeable connections.

Front Plate

The front plates are designed to meet the highest requirements in food processing. The combination of high pressing depth and a pattern with relatively few contact points provides longer operation time without interruptions. The distribution pattern assures an even flow over the entire plate. The port diameters enable cleaning in place (CIP) with the same flow used in the process itself.

Plate Pack

The chevron corrugation of the plates provides a passage between the plates, and supports each plate against the adjacent one. It also enhances the turbulence, resulting in efficient heat transfer. Different chevron angles are available to reach the optimal high heat transfer at a given pressure drop. A unique distribution area provides an efficient flow over the plate surface. The Alfa Laval hanging system enables easy handling of the plates in the frame. In addition, the corner guiding provides for a strong plate pack. The plates are reversible and have parallel flow, which means that only one type of gasket is needed.

Alfa Laval AlfaCond

Alfa Laval AlfaCond

ABS offers Alfa Laval AlfaCond condensers that are specifically designed for condensing of vapour under vacuum. These plate surface condensers are ideal for use in applications such as vacuum condensers in evaporation systems, ethanol condensers in bioethanol plants, pan vapour condensers in sugar refineries, and as turbine condensers in small power plants. With its compact design, AlfaCond is easy to install where space is crucial.

Related Industries:

Agriculture processing, Alumina, Fertilizers, Biotechnology, Biofuels, Renewable power, Food processing, Inorganic chemicals, Pulp production, Copper, Engine power, Petrochemicals, Thermal power, Nuclear power, Paper production

MODELS

- AlfaCond 400

- AlfaCond 600

- AlfaCond 800

Highly efficient and very compact

Highly efficient and very compact, AlfaCond is the world’s first plate condenser specifically designed for condensing under vacuum. Due to its compact size and efficient design, AlfaCond has become the preferred alternative to bulky indirect shell-and-tube condensers. Also, AlfaCond is easy to clean by means of Cleaning-in-Place (CIP) or mechanically.

AlfaCond is an alternative to direct condensers when condensate recovery is the goal and when there are space constraints. The AlfaCond can be configured with or without subcooling of the condensate. Non-condensables are removed from the condensate outlet pipe and led to the vacuum system.

Equipped with well-designed features, AlfaCond heat exchangers are easy to maintain and have a long service life. AlfaCond features the glued gasket, which is a two-component, oven-cured epoxy glue keeps the gasket in place during any possible cleaning condition. Additionally, the pressure plate roller, the bearing boxes on tightening bolts, and the Five-point alignment system with reinforced hangers make opening and closing the heat exchanger quick, and easy without the need for heavy tools or the risk of damaging the plates.

Peace of mind

Alfa Laval global service network is never far away.

Benefits

- Optional sub-cooling of condensate and non-condensable gases

- Flexible configuration

- Easy to install

- High serviceability

- Access to Alfa Laval’s global service network

The heat transfer area of a gasketed plate-and-frame heat exchanger consists of a series of corrugated plates, assembled between the frame and pressure plates, which retain the design pressure. The sealing between the plates on the AlfaCond alternates between laser welds and gaskets. It has a unique porthole configuration that is specifically designed for vacuum condensation. Vapour condenses in the welded channel and the cooling water passes through the gasketed channel.

The channel gap size is asymmetric with a larger gap on the vapour side and a smaller gap on the cooling water side. The result is a very low pressure drop on the vapour side and high velocity and turbulence on the cooling water side. Together, these maximize heat transfer efficiency and minimize fouling.

Alfa Laval WideGap

Alfa Laval WideGap

Alfa Laval WideGap gasketed plate-and-frame heat exchangers are suitable for fibrous fluids and for fluids containing coarse particles. Typical applications for Alfa Laval WideGap heat exchangers are sugar, bioethanol and pulp and paper processes. Depending on the duty, the WideGap heat exchangers that ABS offers can be configured either with wide-wide or wide-narrow channels. This makes the units suitable for heating, cooling and interchanging duties.

MODELS

- WideGap 100

- WideGap 200

- WideGap 350

Related Industries:

Agriculture processing, Fertilizers, Biotechnology, Biofuels, Food processing, Beverage Processing, Pulp production, Paper production

Tailor-made

Alfa Laval WideGap is tailor-made for handling fibrous fluids and for fluids containing coarse particles. The smooth port design ensures that fibres don’t get stuck at the entrance.

Equipped with well-designed features, Alfa Laval WideGap heat exchangers are easy to maintain and have a long service life. Some of the features available include:

- ClipGrip™ gasket – a glue free gasket with superior alignment that ensures a perfect seal and trouble-free maintenance.

- Glued gasket – a two-component, oven-cured epoxy glue keeps the gasket in place during any possible cleaning condition.

Additionally, the pressure plate roller, the bearing boxes on tightening bolts, and the 5 point alignment system with reinforced hangers make opening and closing the heat exchanger quick and easy without the need for heavy tools or the risk of damaging the plates.

Alfa Laval WideGap is quick and easy to modify if process parameters change. Our team’s expertise and the availability of parts bring you peace of mind.

Peace of mind

Alfa Laval global service network is never far away.

Features and benefits

- Maximum uptime for fouling applications

- High energy efficiency

- Flexible configuration

- High serviceability

- Access to Alfa Laval’s global service network

The heat transfer area of a gasketed plate-and-frame heat exchanger consists of a series of corrugated plates, assembled between the frame and pressure plates, which retain the design pressure. The sealing between the plates is made of gaskets. For the highest thermal performance and to enable a very close temperature approach, fluids normally run counter-currently through the heat exchanger. The WideGap heat exchanger is tailor-made to handle fibrous fluids, highly viscous fluids, and fluids containing coarse particles. Because of the plate pattern and pressing depth design, these fluids flow easily through the heat exchanger.

High flow turbulence between plates results in higher heat transfer; however, the consequence is pressure drop. Our thermal design engineers will help you design and select the model and configuration that is suitable for your application needs while delivering maximum thermal performance and minimizing pressure drop.

The WideGap heat exchanger can be configured in many ways. The channels can have either a wide/wide gap or a wide/narrow gap with different channel gaps. WideGap heat exchangers are usually configured as multi-pass in order to ensure enough turbulence.

Alfa Laval AlfaQ Heat Exchanger

Alfa Laval AlfaQ Heat Exchanger

Alfa Laval AlfaQ™ heat exchangers that are offered by ABS are used for HVAC applications such as district cooling substations, ice-storage systems, data centers, and free cooling systems. The range is certified according to the AHRI Liquid to Liquid Heat Exchangers (LLHE) Certification Program which ensures thermal performance according to manufacturers’ published specifications. AHRI certification is the only global, third-party performance certification for plate heat exchangers.

MODELS

- AQ 1

- AQ 1L

- AQ 2

- AQ 2L

- AQ 2S

- AQ 3

- AQ 4

- AQ 4L

- AQ 6

- AQ 6L

- AQ 8

- AQ 8S

- AQ 10

- AQ 14

- AQ 14S

- AQ 14L

- AQ 20M

- AQ 20S

Related Industries:

HVAC Cooling, HCAC Heating, District Cooling, District Heating

AHRI performance certification

The Air Conditioning, Heating and Refrigeration Institute (AHRI) certification is an independent, third-party verification of thermal performance. Through its certification program and standards, AHRI strives to help customers save energy, improve their productivity and help to ensure a better environment.

AHRI Liquid to Liquid Heat Exchanger (LLHE) Certificaiton Program ensures that the product performs in accordance with manufacturers’ published specifications, and is particularly useful in applications such as district cooling substations, ice-storage systems, data centers and free cooling systems.

For more information, visit Alfa Laval’s HVAC AHRI perfomance certification page .

Well-designed and long service life

Alfa Laval AlfaQ™ gasketed plate-and-frame heat exchangers are available to meet most heat transfer requirements – whether large or small – demonstrating our commitment to optimizing the performance of our customers’ processes.

Equipped with well-designed features the heat exchangers are easy to maintain and have a long service life. Some of the features available include:

- ClipGrip™ gasket – a glue free gasket with superior alignment that ensures a perfect seal and trouble-free maintenance.

- Glued gasket – a two-component, oven-cured epoxy glue that keeps the gasket in place during any possible cleaning condition.

- CurveFlow™ distribution area – ensures full use of the heat transfer area and minimizes fouling.

Additionally, the pressure plate roller, the bearing boxes on tightening bolts, and the 5 point alignment system with reinforced hangers make opening and closing the heat exchanger quick and easy without the need for heavy tools or the risk of damaging the plates.

AlfaQ™ is quick and easy to modify if process parameters change. Our team’s expertise and the availability of parts bring you peace of mind.

Plate types for different needs

AlfaQ™ is available with two different plate configurations:

- Single plate with a chevron pattern design for parallel flow allowing for optimum thermal performance and pressure drop.

- Single plate with a chevron pattern design for diagonal flow through the heat exchanger when it is mounted horizontally and requires draining.

Peace of mind

Alfa Laval global service network is never far away.

The Air-Conditioning, Heating, and Refrigeration Institute (AHRI) Product Performance Certification Programme is a voluntary programme, administered and governed by AHRI, which ensures that various types of heating, ventilation, air conditioning, refrigeration, and water heating products perform according to manufacturers’ published claims.

Products that are certified through the AHRI Product Performance Certification Programme are continuously tested, at the direction of AHRI, by an independent third-party laboratory, contracted by AHRI, to determine the product’s ability to conform to one or more product rating standards or specifications.

Benefits

- High energy efficiency

- Flexible configuration

- Easy to install

- High serviceability

- Access to Alfa Laval’s global service network

The heat transfer area of a gasketed plate-and-frame heat exchanger consists of a series of corrugated plates, assembled between the frame and pressure plates, which retain the design pressure. The sealing between the plates is made of gaskets. For the highest thermal performance and to enable a very close temperature approach, fluids normally run counter-currently through the heat exchanger.

AlfaQ™ is available with various pressing depths and angles of the chevron pattern and various shapes of the corrugation which are carefully designed and selected to achieve optimum performance. The CurveFlow™ and the chocolate pattern distribution area are two design features available that ensure fluids are evenly distributed across the entire plate. The result is that the entire heat transfer surface is fully utilized and stagnant zones that can result in fouling are avoided.

High flow turbulence between plates results in higher heat transfer; however, the consequence is pressure drop. Our thermal design engineers will help you design and select the model and configuration that is suitable for your application needs while delivering maximum thermal performance and minimizing pressure drop.

Alfa Laval AlfaVap Semi-Welded Heat Exchanger

Alfa Laval AlfaVap Semi-Welded Heat Exchanger

ABS offers Alfa Laval’s AlfaVap semi-welded heat exchangers that are tailor-made, rising film plate evaporators and are suitable when concentration and viscosity of media are high. Typical applications for AlfaVap are sugar refinery evaporation systems, sweeteners evaporation systems, bioethanol and caustic evaporation. It is also suitable as a thermosiphon reboiler. Its compact design makes it ideal to install at elevated levels.

MODELS

- AlfaVap 350

- AlfaVap 500

- AlfaVap 650

- AlfaVap 700

Related Industries:

Agriculture processing, Fertilizers, Biotechnology, Biofuels, Food processing, Petrochemicals, Renewable power, Inorganic chemicals, Copper, Thermal power, Nuclear power

Unique design for thermal efficiency

Alfa Laval’s AlfaVap unique design provides higher thermal efficiency than the traditional shell-and-tube evaporators and because of this much less heat transfer area is needed. AlfaVap heat exchangers are cost-efficient especially when exotic metal materials are required.

AlfaVap’s advantage is that they work also when the temperature differential between the hot and cold fluids approaches as low as 2.5°C (4.5°F) meaning that lower grade steam and more effects in series can be use in an evaporation system compared to the shell-and-tube systems. This saves steam costs.

Compact design and versatility

The compact design and versatility of the AlfaVap means that they are cost-efficient and easily installed even at high elevations.

AlfaVap heat exchangers are easily accessible for inspection and mechanical cleaning by removing the tightening bolts and rolling back the pressure plate. For Cleaning-in-Place (CIP), only a small amount of cleaning chemicals is needed because of their low hold-up volume.

AlfaVap’s design makes it easy to adjust evaporation capacity to meet changing needs by adding or removing plates to the existing frame. This is a major advantage over shell-and-tube units where the capacity cannot be changed once it’s installed.

Equipped with well-designed features, the AlfaVap heat exchangers are easy to maintain and have a long service life. They feature a clip-on gasket which is a glue free gasket that ensures perfect sealing and trouble-free maintenance. Additionally, the pressure plate roller, the bearing boxes on tightening bolts, and the Five-point alignment system with reinforced hangers make opening and closing the heat exchanger quick and easy without the need for heavy tools or the risk of damaging the plates.

Peace of mind

Alfa Laval global service network is never far away.

Benefits

- Low hold-up volume

- High energy efficiency

- Easy to install

- High serviceability

- Access to Alfa Laval’s global service network

The heat transfer area of a gasketed plate-and-frame heat exchanger consists of a series of corrugated plates, assembled between the frame and pressure plates, which retain the design pressure. The sealing between the plates on the AlfaVap alternates between laser welds and gaskets. Alfa Laval AlfaVap is tailor-made for evaporation. It has two inlet feed connections located centrally at the bottom of the frame plate and a large outlet for the vapour and concentrate at the top. The heating steam condenses in the welded channels and the evaporating product passes through the gasketed channels.

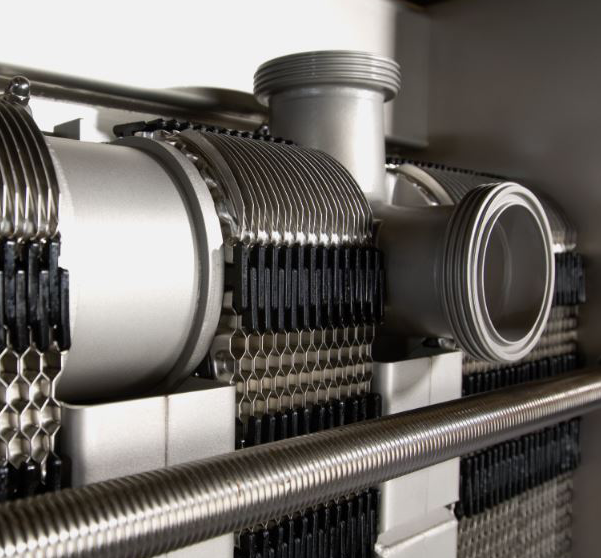

Industrial semi-welded line

Industrial semi-welded line

Alfa Laval Industrial semi-welded line is used when gaskets are not suitable for one of the process media. Also, the semi-welded line can take a higher design pressure compared to fully gasketed plate-and-frame heat exchangers.

MODELS

- M10W

- M6W

- MA30W

- MK15

- T20

- TK20W

Unique sealing system

Alfa Laval Industrial semi-welded line handles most refrigerants and is particularly suitable for applications involving ammonia. Semi-welded heat exchangers are used in both organic and inorganic chemical processing when the chemicals involved limit the selection of gaskets that can be used or when the required design pressure makes fully gasketed plate-and-frame heat exchangers insufficient.

The media passes through the welded channel facing the ring gasket sealing between the laser welded cassettes. Alfa Laval semi-welded heat exchangers employ the Alfa Laval RefTight™, a unique sealing system which guarantees high performance by positioning the laser weld on the outside of the ring gasket groove. The smooth ring gasket grove ensures equal sealing force over the entire porthole gasket.

Equipped with well-designed features, Alfa Laval Industrial semi-welded line of heat exchangers are easy to maintain and have a long service life. Some of the features available include:

- ClipGrip™ gasket – a glue free gasket with superior alignment that ensures a perfect seal and trouble-free maintenance.

- Alfa Laval RefTight™ – a unique gasket groove design with maximum gasket support and minimum gasket contact.

- CurveFlow™ distribution area – ensures full use of the heat transfer area and minimizes fouling.

Peace of mind

Alfa Laval global service network is never far away.

Benefits

- High energy efficiency

- Flexible configuration

- Easy to install

- High serviceability

- Access to Alfa Laval’s global service network

The heat transfer area of a gasketed plate-and-frame heat exchanger consists of a series of corrugated plates, assembled between the frame and pressure plates, which retain the design pressure. For the highest thermal performance and to enable a very close temperature approach, fluids normally run counter-currently through the heat exchanger.

The sealing between the plates on the Industrial semi-welded line alternates between laser welds and gaskets. The laser welded channel allows use of fluids that are not compatible with normal gaskets and also allows for higher design pressure than fully gasketed plate-and-frame heat exchangers. Additionally, the Alfa Laval RefTight™ sealing system guarantees equal sealing force over the entire porthole gasket.

Industrial semi-welded line is available with various pressing depths and angles of the chevron pattern and various shapes of the corrugation which are carefully designed and selected to achieve optimal performance. The CurveFlow™ and the chocolate pattern distribution area are two design features available that ensure fluids are evenly distributed across the entire plate. The result is that the entire heat transfer surface is fully utilized and stagnant zones that can result in fouling are avoided.

High flow turbulence between plates results in higher heat transfer; however, the consequence is pressure drop. Our thermal design engineers will help you design and select the model and configuration that is suitable for your application needs while delivering maximum thermal performance and minimizing pressure drop.

The Industrial semi-welded line can be configured in many ways. The animation shows single pass configuration of a fully gasketed plate-and-frame heat exchanger. The flow principle of a semi-welded heat exchanger is the same. The difference is that every second channel is sealed with a laser weld instead of a gasket. Multi pass with 2 or more passes on each side is also possible.

Alfa Laval Diabon Heat Exchanger

Alfa Laval Diabon Heat Exchanger

ABS offers the Alfa Laval Diabon® plate-and-frame heat exchangers that are used for tough corrosive media. This range of heat exchangers combine Alfa Laval’s know-how in heat transfer with Germany based SGL Carbon’s expertise in graphite process equipment. Alfa Laval Diabon® gasketed plate-and-frame heat exchanger combines high-efficiency heat transfer benefits with the exceptional corrosion resistance of graphite material.

Alfa Laval and SGL Carbon, Germany, worked together to develop DIABON® plate heat exchangers. This collaborative effort combines Alfa Laval’s plate heat exchanger know-how with SGL Carbon’s expertise in graphite process equipment. The resulting product combines the high-efficiency heat transfer benefits of conventional plate heat exchangers with the exceptional corrosion resistance of graphite material.

DIABON® plate heat exchangers are therefore ideal for handling highly corrosive fluids such as:

- hydrochloric acid and gas in all concentrations

- sulphuric acid up to 90%

- hydrofluoric acid up to 60%

- all concentrations of phosphoric acid

- pickling acids in surface treatment plants

- electrolytes used in the mining industry

- mixed acids

- chlorinated hydrocarbons

- catalysts such as aluminium chloride.

Alfa Laval DIABON® plate heat exchangers work on the same principle as conventional plate heat exchangers, except that the plates separating the media are made of special graphite materials.

The graphite plates are available in three different material grades, DIABON® F100, NS1 or NS2. The channels formed when these graphite plates are assembled in a plate pack are sealed by PTFE gaskets.

In addition, the tightening bolts on the frame are fitted with springs to compensate for thermal expansion of the plate pack, hence minimizing the risk of cracking the plates.

PTFE rope gasket

Alfa Laval DIABON® plate heat exchangers are all supplied with a PTFE rope gasket. When the heat exchanger is assembled, this gasket rope is flattened to a very thin film approx. 0.2 mm).

The thinness of the gasket means that the area in contact with the chemical is very limited, resulting in an extremely long service life. To date, the gasket has proved resistant to attack by all known chemicals, as well as resisting very high temperatures (>180°C).

In addition, the gasket can be kept in storage for virtually unlimited periods.

Applications

Heaters, coolers, interchangers, condensers and evaporators

for corrosive media, especially in the treatment of:

-Hydrochloric acid (HCl)

-Sulfuric acid (H2SO4)

-Hydrofluoric acid (HF)

-Mixed Acids (HNO3/HF)

-Phosphoric acid (H3PO4/P2O5)

-Other organic and inorganic media

Standard design

The graphite plate heat exchanger consists of a pack of

corrugated graphite plates with portholes for the passage of

the two fluids between which heat transfer will take place.

The plate pack is assembled between a carbon steel fixed

frame plate and movable pressure plate and compressed by

tightening bolts. The difference in coefficients of expansion of

carbon steel and graphite is compensated for by means of

helical springs.

The plates are fitted with a film type PTFE gasket of 0,2 mm

thickness after tightening, which seals the interplate channel

and directs the fluids into alternate channels. The number

of plates is determined by the flow rate, pressure drop and

temperature program. The plate corrugations promote fluid

turbulence and minimize fouling.

The frame plate and pressure plates are suspended from an

upper carrying bar and located by a lower guiding bar, both of

which are fixed to a support column. Connections are located

in the frame plate or, if either or both fluids make more than a

single pass within the unit, in the frame and pressure plates.

The frame and pressure plates are protected from the

corrosive media by means of a PTFE lining.

Typical capacities

Max flow rate of 250 m3

/h, depending on media, permitted

pressure drop and temperature program.

Plate types: S1, M10-G, S10, S15.

Frame types: One standard frame available that can be

modified to higher design pressures.

Working principle

Channels are formed between the plates and the corner ports

are arranged so that the two media flow through alternate

channels. The heat is transferred through the plate between

the channels, and complete counter current flow is created for

the highest possible efficiency. The corrugation of the plates

provides the passage between the plates, supports each

plate against the adjacent one and enhances the turbulence,

resulting in efficient heat transfer.

Standard materials

Plates: F100, NS1/NS2

Alfa Laval Industrial Line Heat Exchanger

Alfa Laval Industrial Line Heat Exchanger

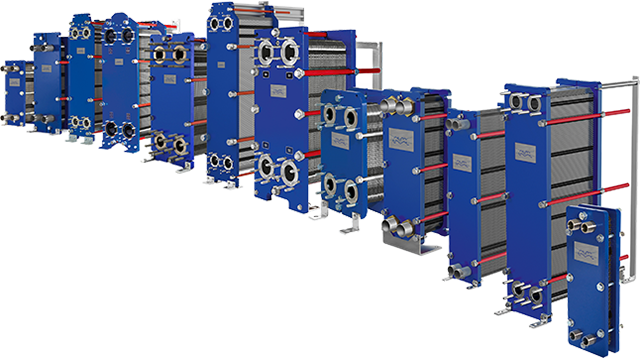

Alfa Laval Industrial line is an extremely wide range of gasketed plate-and-frame heat exchangers used in all types of industries. The number of sizes, plate and gasket materials and available options are enormous. Every detail is carefully designed to ensure optimal performance, maximum uptime, and easy maintenance.

Versatile design

The Industrial line’s versatility allows it to be designed and configured for applications ranging from relatively simple duties with low requirements to very demanding duties with the highest requirements on both performance and documentation. The products are used for heating, cooling, heat recovery, condensation, and evaporation.

Equipped with well-designed features, the Industrial line of heat exchangers are easy to maintain and have a long service life. Some of the features available include:

- ClipGrip™ gasket – a glue free gasket with superior alignment that ensures a perfect seal and trouble-free maintenance.

- Glued gasket – a two-component, oven-cured epoxy glue keeps the gasket in place during any possible cleaning condition.

- CurveFlow™ distribution area – ensures full use of the heat transfer area and minimizes fouling.

Additionally, the pressure plate roller, the bearing boxes on the tightening bolts, and the Five-point alignment system with reinforced hangers make opening and closing the heat exchanger quick and easy without the need for heavy tools or the risk of damaging the plates.

Alfa Laval Industrial line is quick and easy to modify if process parameters change. Our team’s expertise and the availability of parts bring you peace of mind.

Plate types for different needs

Industrial line is available with four different plate configurations:

- Single plate with a chevron pattern design for parallel flow allows for optimum thermal performance and pressure drop.

- Single plate with a chevron pattern design for diagonal flow allows for optimum thermal performance through the heat exchanger when it is mounted horizontally and requires complete drainability.

- Double wall plate is used when extra care is needed to avoid mixing fluids.

- Gemini double wall plate is used when extra care is needed to avoid mixing fluids in hygienic applications.

The heat transfer area of a gasketed plate-and-frame heat exchanger consists of a series of corrugated plates, assembled between the frame and pressure plates, which retain the design pressure. The sealing between the plates is made of gaskets. For the highest thermal performance and to enable a very close temperature approach, fluids normally run counter-currently through the heat exchanger.

The Industrial line is available with various pressing depths and angles of the chevron pattern and various shapes of the corrugation which are all carefully designed and selected to achieve optimal performance. The CurveFlow™ and the chocolate pattern distribution area are two design features available that ensure fluids are evenly distributed across the entire plate. The result is that the entire heat transfer surface is fully utilized and stagnant zones that can result in fouling are avoided.

High flow turbulence between plates results in higher heat transfer; however, the consequence is pressure drop. Our thermal design engineers will help you design and select the model and configuration that is suitable for your application needs while delivering maximum thermal performance and minimizing pressure drop.