Circpac MD Specialty Seal

Circpac MD Specialty Seal

Circpac MD Specialty Seal

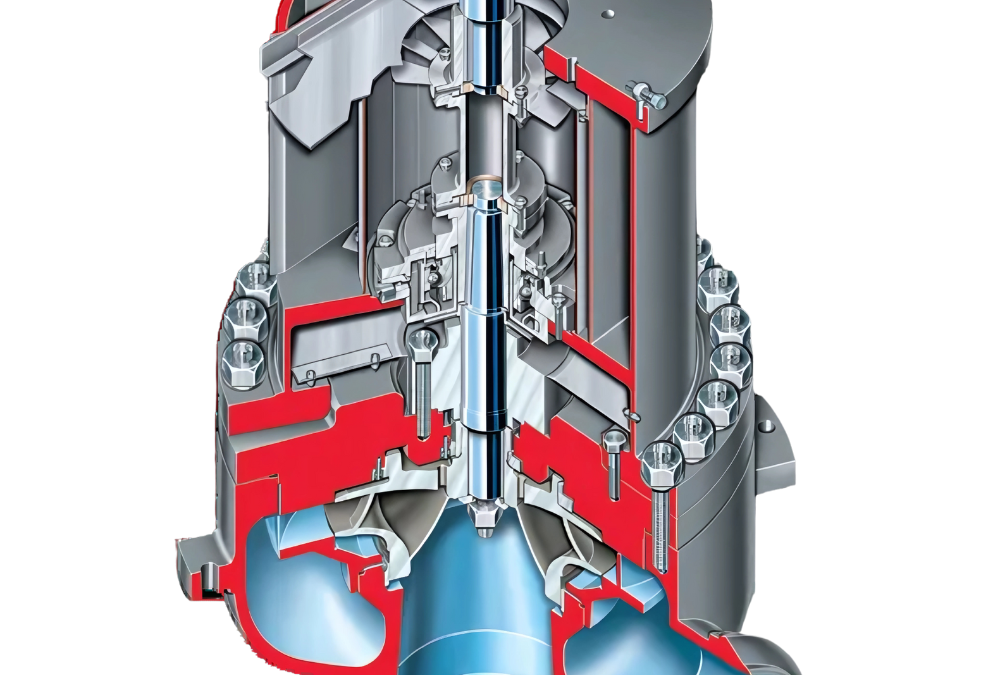

Circpac MD seals are segmented circular seals designed for centrifuges, fans, blowers, dryers, turbines, and other rotating machinery. Circpac MD seals come in a split housing, making them simple to install. Standard designs always outperform packing, bushings, labyrinths and felt seals, requiring less gas in a wider range of applications.

Fans, blowers, dryers, turbines, centrifuges and other spinning equipment all use segmented circumferential seals. It comes with an easy-to-install split housing. Standard designs always outperform packing, bushings, labyrinths and felt seals because they utilize less gas and are applicable in a wider range of conditions.

Circpac MD Specialty Seal with Circumferential for Industrial Applications

Benefit

- Floating circumferential rings are designed to work for a long time. Hydraulically balanced rings with hydrodynamic surface features allow for higher maximum pressures, temperatures, and speeds than conventional circumferential seals.

- The radially split seal case can be installed without disassembling the equipment. The seal attaches outside the seal chamber, making installation easier and reducing downtime.

- Strong carbon rings can withstand handling during installation and in difficult conditions. Carbon rings are simple to assemble and stay together even when they aren’t supposed to, thanks to foul-resistant joints and large bearing pads.

- The large housing clearance allows for equipment heat growth and shaft misalignment. Standard radial clearances of up to 6 mm (0.25 inch) are suitable for a variety of equipment types.

- Multiple ring designs offer a cost-effective way to meet different application needs. Rings can be staged to reduce leakage, pressurized to eliminate process emissions, or extra rings can be added in case of an emergency.

- Construction materials are chosen based on their compatibility with other materials. To meet temperature and corrosion resistance standards, various material grades can be used.

- The Circpac MD seal costs less to operate than typical circular or labyrinth seals because it utilizes less gas. This simplifies the gas control mechanism.

Specification

Pressure: vacuum to 6.9 bar (100 psi)

Temperature: -40 to 593°C (-40 to 1100°F)

Speed: up to: 46 m/s (150 fps)

Sizes: 35 to 457 mm (1.375 to 18.000 inches)

Configurations

Single ring

Low pressures

Tandem rings

Process vent or drain

Double rings

Inert barrier gas injection

Triple rings

Inert barrier gas injection

Lower barrier gas consumption rate

Quadruple rings

High pressure

Multiple vent, drain, or barrier gas injection ports

Related Industries

- Water

- Wastewater

- Oil & Gas

- Downstream Processing

- General Industries

- Steel & Primary Metals

Circpac MD – Installation Instructions

Enhance your operations with the Circpac MD specialty seal. Contact us today to learn how it can optimize your industrial and water sealing needs.