B50 Hygienic Pump

B50 Hygienic Pump

B50 Hygienic Pump

The B50 Hygienic Pump is a high-capacity air operated double diaphragm pump (AODD) designed for the sanitary transfer of viscous and sensitive fluids. Built with 316L stainless steel and FDA-compliant elastomers like EPDM and PTFE, the B50 delivers superior performance for large-scale food, beverage, dairy, pharmaceutical and chemical processing.

With a flow rate of up to 500 ltrs/min (132 gal/min) and 10 mm solid handling, this pump is ideal for operations requiring robust, hygienic and compliant fluid handling.

Key Features

- Available with DIN, RJT, and Ferrule hygienic connections

- Self-priming design, efficient for tank or drum emptying

- FDA-approved materials (EPDM, PTFE, Viton®) for safe fluid transfer

- Certified for CIP (Clean-in-Place) and ATEX hazardous zone use

- Up to 8.6 bar (125 PSI) pressure handling

- 316L stainless steel construction for maximum corrosion resistance

- Optional pump stand with 180° rotation for easier cleaning and maintenance

- Handles high-viscosity and high specific gravity (S.G.) fluids with ease

Technical Specifications

| Parameter | Details |

| Maximum Delivery | 500 ltrs/min (132 gal/min) |

| Max. Working Pressure | 8.6 bar (125 PSI) |

| Max. Solid Particle Size | 10 mm (0.39″) |

| Air Inlet | 3/4″ NPT |

| Temperature Limits | Determined by elastomers |

| Suction Lift (Dry) | 6.1 metres (20 feet) |

| Suction Lift (Wet) | 7.6 metres (24.9 feet) |

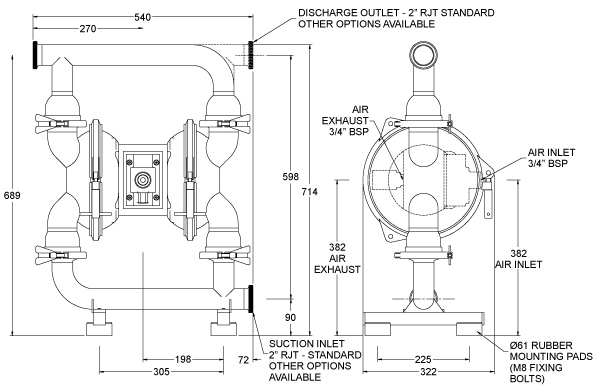

| Fluid Inlet / Outlet | 2″ RJT (standard) |

| Installation | Surface mounted |

| Accessories Included | Exhaust Air Silencer |

| Shipping Weight | 64 kg (141.1 lbs) – Stainless Steel |

| Shipping Dimensions | 660 x 430 x 880 mm (26″ x 16.9″ x 34.7″) |

Material & Temperature Compatibility

Choose from a wide range of diaphragm materials to suit different process fluids and temperature conditions:

| Material | Max Temp (°C/°F) | Min Temp (°C/°F) | Optimal Range (°C/°F) | Key Features |

| Buna-N | 80°C / 176°F | -28°C / -18°F | 10–60°C / 50–140°F | Good oil resistance |

| EPDM | 100°C / 212°F | -24°C / -11°F | 10–100°C / 50–212°F | Strong water/alkaline resistance |

| Neoprene | 100°C / 212°F | -20°C / -4°F | 10–54°C / 50–130°F | Moderate chemical use |

| Santoprene® | 100°C / 212°F | -23°C / -10°F | 10–100°C / 50–212°F | Long flex life |

| PTFE (Teflon) | 180°C / 356°F | 0°C / 32°F | 10–100°C / 50–212°F | Chemically inert |

| Viton® | 180°C / 356°F | -18°C / 0°F | 24–100°C / 75–212°F | Best for solvents & aggressive fluids |

| Polypropylene | 70°C / 158°F | -40°C / -40°F | 10–60°C / 50–140°F | Lightweight & cost-effective |

B50 Hygienic Pump Applications

- Food & Beverage: Syrups, sauces, dairy, flavor concentrates

- Pharmaceutical: Aseptic liquid transfer, CIP systems

- Cosmetics & Personal Care: Creams, gels, essential oils

- Chemical & Solvent Handling: Acids, detergents, alcohols

- Biotech & Processing: Nutrient solutions, sanitary waste

Frequently Asked Questions (FAQ)

Q1: Is the B50 pump CIP cleanable?

Yes, the B50 is certified CIP-cleanable, making it perfect for hygienic applications.

Q2: What’s the main use case for the B50 compared to B25?

The B50 is designed for higher capacity transfer (up to 500 ltrs/min) and larger solids (10 mm), making it ideal for high-demand operations.

Q3: Can this pump be used in hazardous zones?

Yes, it’s ATEX certified, suitable for explosive environments.

Q4: Does it support high-viscosity fluids?

Absolutely. The B50 is engineered for thick, viscous liquids and high-S.G. media.

Q5: What elastomer options are available?

You can choose from EPDM, PTFE, Viton®, Santoprene®, and Buna-N, depending on chemical compatibility and temperature needs.

Achieve high-capacity efficiency in sanitary operations with the Alfa Laval B50 Hygienic Pump. Get in touch to learn how it fits your needs.