Alfa Laval Pharma X Heat Exchanger

Part of a broad heat exchanger range

Alfa Laval offers a comprehensive range of heat exchangers for use in hygienic and Pharmaceutical applications.

These include:

Alfa Laval Pharma X Heat Exchanger

Alfa Laval Pharma X Heat Exchanger

A compact heat exchanger module developed for point of use cooling in pharmaceutical water systems. Alfa Laval Pharma-X is designed to remain sanitized even when not in use (standby mode).

Related Industries:

Biotechnology, Pharmaceutical Production

Efficient point of use cooling

Easy installation

Alfa Laval Pharma-X is build as a plug-and-play module for any installation. For quick and easy installation, the Pharma-X is supplied as a complete insulated module with a pitot tube arrangement and either manual or automatic valves.

Installed in a water system, the Pharma-X module can be regarded as a sub-loop of the main loop.

Hygienic design

The Pharma-X meets the stringent hygienic standard imposed by both control authorities and industry.

Unique design

Designed to eliminate risk of contamination. No internal welds, and fully drainable on the product side with no dead legs.

All product wetted parts in the Pharma-X are electropolished and the tubes as seamless.

Quick response

When switching from ‘stand-by mode’ to ‘cooling mode’, cold water is available within seconds.

Fast and efficient

The low hold-up volume and quick heat exchanger response mean cold water is available within seconds and waste of water for injection and purified water is minimized.

Minimum maintenance

The Pharma-X is virtually maintenance free with no internal gaskets.

Standard sizes

The Pharma-X is available in four standard sizes with a heat transfer area ranging from 0.3 m2 to 1.0 m2, allowing a flow rate up to 1000 or 1500 l/h.

Tube-in-tube

The product has a unique design that gives high shear force and turbulence. This minimizes risk of bio-film build-up and ensures an efficient heat transfer. This in turn means that less cooling water is needed.

The Pharma-X heat exchanger is made up of three tubes positioned concentrically within each other.

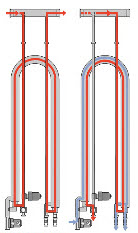

Operating principles

The product flows in the centre channel (fig. 1) meeting the service media in the inner and outer channel to get full countercurrent flow and thereby efficient heat transfer.

Installed as a complete point-of-use cooler the heat exchanger is kept sanitized all the time. In stand-by mode (fig. 3), part of the hot WFI is taken via the pitot tube (fig. 2) for a continuous flow through the heat exchanger. Hot WFI is possible to take out through the user point. When cold WFI is needed, the cooling mode (fig. 4) is turned on by an air switch, which closes the recirculation valve and opens the cooling water valve. Cold WFI is available within seconds and no need for flushing or draining of the system before drawing WFI or PW.