TKL

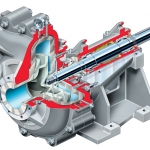

Dual Casing provides access to elastomeric or hard metal liners for inspection or replacement. Machined mating faces provide proper liner compressions.

Elastomeric and Hard Metal Liners are fully interchangeable, allowing the most economical material to be used.

High-Efficiency, Closed Vane Impeller has adjustable face clearance and generous wear allowance. Threaded shaft to impeller design eliminates troublesome impeller nut.

Titan™ Slurry Heavy-Duty, Overhung, Radially Split, Lined Pump

Titan™ Slurry Heavy-Duty, Overhung, Radially Split, Lined Pump

| Brand: | TKL |

|---|---|

| Description: | The Flowserve Titan Slurry pump is a true mill circuit slurry pump. It reflects the company’s innovation and engineering… |

The Flowserve Titan Slurry pump is a true mill circuit slurry pump. It reflects the company’s innovation and engineering expertise in hydraulic design, materials science and manufacturing excellence.

- Applications:

Construction, Dewatering and Water Supply (mining), Digester, Flue Gas Desulfurization, Food Processing, Water Treatment, Primary Processing (mining), Scale Recycle, Sewage Collection and Treatment, Slurry Transfer (mining), Leaching Acid - Industries:

General Industries, Mining, Water Resources, Primary Metals, Pulp and Paper, Power Generation

Dual Casing provides access to elastomeric or hard metal liners for inspection or replacement. Machined mating faces provide proper liner compressions.

Elastomeric and Hard Metal Liners are fully interchangeable, allowing the most economical material to be used.

High-Efficiency, Closed Vane Impeller has adjustable face clearance and generous wear allowance. Threaded shaft to impeller design eliminates troublesome impeller nut.

Removable Stuffing Box converts to various shaft sealing options without modification to the shaft, liner or impeller.

Bearing Cartridge incorporates back-to-back taper roller bearings to carry axial and belt loads. A roller bearing

Operating Parameters:

- Flows to 3600 m3/h (16 000 gpm)

- Heads to 90 m (300 ft)

- Pressures to 40 bar (580 psi)

- Sizes from 50 mm (2 in) to 350 mm (14 in)

TKL™ Titan™ Slurry Heavy-Duty, Dual Case Lined Pump Bulletin

Flowserve TKL™ Titan™ Slurry Heavy-Duty, Dual Case Lined Pump Sales Bulletin

Terra-Titan™ Cantilever Vertical Sump Pump

Terra-Titan™ Cantilever Vertical Sump Pump

| Brand: | TKL |

|---|---|

| Description: | The Flowserve TKL™ Terra-Titan vertical, cantilever sump pump is ruggedly built to provide the economical reliability demanded… |

The Flowserve TKL™ Terra-Titan vertical, cantilever sump pump is ruggedly built to provide the economical reliability demanded by the mining, process and general industries.

- Applications:

Food Processing, Water Treatment, Flue Gas Desulfurization, Leaching Acid, Primary Processing (mining), Digester, Sewage Collection and Treatment, Slurry Transfer (mining), Construction, Dewatering and Water Supply (mining), Scale Recycle - Industries:

Mining, Power Generation, General Industries, Pulp and Paper, Water Resources, Primary Metals

One-Piece Suspended, Oversized Cantilever Shaft Design is inherently rigid, reduces vibration and enables the pump to operate under run-dry conditions.

Double Suction, Open Impeller is hydraulically balanced and prevents air-lock and solids accumulation.

Renewable Terraprene Shaft Sleeve eliminates shaft wear within the pump casing.

External Impeller Adjustment provides a simple, fast and easy way to adjust impeller clearances for special applications.

Heavy-Duty Self-Aligning Roller Bearings are greased for life and fitted in common bearing housing.

Operating Parameters

- Flows to 250 m3/h (1100 gpm)

- Heads to 45 m (150 ft)

- Pressures to 5 bar (70 psi)

- Temperatures to 100°C (212°F)

- Sizes from 40 mm (1.5 in) to 125 mm (5.0 in)

- Sump depths from 700 mm (28 in) to 1800 mm (72 in)

TKL™ Terra-Titan™ Vertical Cantilever Shaft Sump Pump Sales Bulletin

TKL™ Terra-Titan™ Vertical Cantilever Shaft Sump Pump Sales Bulletin

MVE End Suction, Overhung Industrial Process Pump

MVE End Suction, Overhung Industrial Process Pump

| Brand: | TKL |

|---|---|

| Description: | The MVE mixed flow, single stage volute pump is designed to deliver high volume flow at low to medium heads. It provides… |

The MVE mixed flow, single stage volute pump is designed to deliver high volume flow at low to medium heads. It provides reliable performance in numerous industrial, municipal and agriculture services.

- Applications:

Agriculture, Dewatering and Water Supply (mining), Flood Control, Water Treatment, Sewage Collection and Treatment, Shipping, Waste Processing, Ground Water Development and Irrigation

Single volute, symmetrical casing features integral suction and discharge flanges for high strength. End suction and side discharge standard; top discharge optional.

Mixed Flow, Enclosed Impeller is mechanically balanced to prevent vibration.

Heavy-Duty angular contact radial and thrust bearings are standard.

Back pull-out design permits removal without disturbing piping.

Seal chamber accommodates packing and multiple mechanical seal types.

Operating Parameters

- Flows to 2700 m3/h (11 890 gpm)

- Heads to 15 m (50 ft)

- Pressures to 7 bar (100 psi)

- Temperatures to 100°C (212°F)

TKL EC Between Bearings Pump

Brand |

Description |

| TKL | The EC is a multistage horizontal split case pump developed for mining and water transportation applications requiring high flow and head. It can be installed both horizontally and vertically. |

TKL EC Between Bearings Pump – Radially Split, Single Case for Water Management and Mining Features

The EC is a multistage, horizontal split case pump, designed to support large flow and high head applications in mining and water transmission applications. It can be mounted horizontally or vertically.

-

Radially Split Single Case Pump Applications:

Heavy Oil, Oil Sands and Shale, Molten Salt Transfer, Offsites and Waste Treatment, Renewable Fuel Production, Shipping, Water Supply and Treatment (oil and gas), Auxiliary (chemical), Drilling and Production, Flood Control, Ground Water Development and Irrigation

-

Industries:

Chemical Processing, General Industries, Mining, Pulp and Paper, Water Resources

Horizontally Split Casing allows access to the pump internals without removing the suction and discharge connections.

Pump Rotor can be removed without disturbing the motor or alignment which simplifies maintenance.

The pump can be mounted horizontally or vertically to suit application piping requirements.

Shaft Sleeves between the stages and in the stuffing boxes reduce friction wear.

Stuffing Boxes are furnished with graphite impregnated packing which provides easy maintenance and leakage adjustment for long life.

Operating Parameters

- Flows to 2340 m3/h (10 300 gpm)

- Heads to 650 m (2130 ft)

- Pressures to 88 bar (1300 psi)

- Temperatures from -30°C (-20°F) to 150°C (300°F)