SIHI Side Channel Pumps (in Compact design)

Series CEH

Series CEH

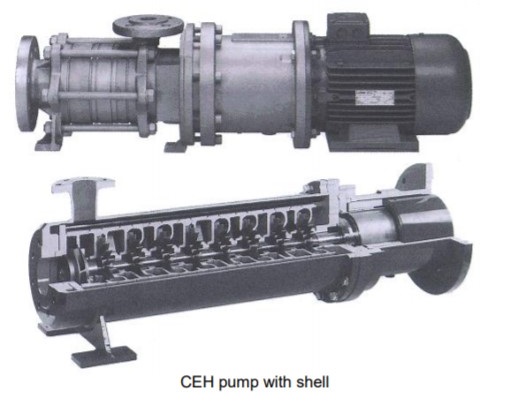

Pumps of the series CEH have a segmental type construction with open vane wheel impellers. The construction of the CEH pump is a so-called centrifugal combined system. This combination pump is suited with a centrifugal stage in serial connection before the side channel stages to obtain a more favourable NPSH.

Applications:

The CEH pumps are used for problem-free pumping of clean liquids at unfavourable suction side conditions. They are also very suitable for positive suction heads below 0.5 m. The different material possibilities with uniform dimensions and performance characteristics as well as the standard exchangeable components, make the CEH particularly recommendable for applications in the pharmaceutical, chemical or petrochemical market as well as in the plastic or oil industry. Because of its low NPSH and positive suction head the CEH is very suitable for the pumping of liquefied gasses and liquids under vapour pressure like condensate, refrigerant, boiler feed water or LPG. The pumps of the CEH /7 series have a retaining stage to avoid the dry running by controlling the liquid level in the pump. This design is especially developed for the handling of liquids under vapour pressure or when pumping from underground tanks. The series CEH /5 are used for bottom off-loading of liquids under vapour pressure.

Technical Data:

Flow rate: up to 35 m³/h

Head: up to 354 m

Speed: max. 1800 rpm

Temperature: max. 180 °C

Casing pressure: up to 40 bar

Shaft seals: magnetic drive

Materials: grey cast iron, nodular iron, stainless steel

Series AEH

Series AEH

Pumps of the series AEH according to EN 734 have a segmental type construction with open vane wheel impellers. This pump is available in a normal industrial design with one liquid surrounded slide bearing and one ball bearing or in a heavy-duty construction with a double ball bearing design.

Applications:

The AEH pumps were especially developed for difficult applications in all industry sectors and are thus applied when pure, turbid or aggressive media have to be pumped under difficult conditions without any problems. The different material possibilities with uniform dimensions and performance characteristics as well as the standard exchangeable components, make the AEH particularly recommendable as universal pump for all possible pumping problems. This results in a wide application range in many sectors such as chemical industry, petrochemical industry, pharmaceutical industry, OEM, oil industry and food industry.

Technical Data:

Flow rate: up to 35 m³/h

Head: up to 354 m

Speed: max. 1800 rpm

Temperature: max. 180 °C

Casing pressure: up to 40 bar

Shaft seals: magnetic drive

Materials: grey cast iron, nodular iron, stainless steel

Series SC

Series SC

Pumps of the series SC have a segmental type construction with open vane wheel impellers. The construction of the SC pump is a so-called centrifugal combined system. This combination pump is suited with a centrifugal stage in serial connection before the side channel stages to obtain a more favourable NPSH. This pumps a especially designed to the LPG filling stations.

Applications:

The SC is, due to its special design, very suitable for problem-free pumping of clean liquids at unfavourable suction side conditions. The SC can also be used for NPSHA of 0,4 – 0,65 m. The SC is especially developed for LPG-plants (pumping of propane, butane and bottom off-loading).

Technical Data:

Capacity: up to 65 l/min

Differential pressure: up to 14.5 bar

Speed: max. 2,900 rpm

Temperature: max. 80 °C

Casing pressure: up to 40 bar

Shaft seals: mechanical seal, magnetic drive

Materials: nodular iron

Series SMX

Series SMX

The SIHI pump type SM-X that ABS offers is an innovative product that can be dropped in place to the other usual submersible pumps used in most of the LPG car filling stations.

Due to its design, this pump can be installed without bypass valve as an internal bypass secure the minimum flow of the pump.

The well-known reliability of the side channel pump is combined with the safe use and the simple design of a submersible pump.

An optional intelligent drive allows to use one pump for 2 nozzles and reduce the energy consumption by adjusting the performance to the exact need of the installation.

Applications:

LPG car filling stations have different configurations depending on countries and local regulations. The submersible pumps are used all over the world to avoid any installation and piping above the ground which lead to better safety and cleanest station design.

Technical Data:

Volume flow: up to 100 l/min

Differential pressure: up to 10 bar

Speed: max. 3,400 rpm

Temperature: max. 40 °C

Shaft seals: sealless

Series CEB

The CEB side channel units are a low noise design of combination pump. They are ideal for pumping liquids that are stored at their boiling point, have a degree of entrained gas, or very low NPSH conditions. The vertical tank pump has been designed in order to enable retro-fitting into most common tanks. Moreover, the dimensions are such that the unit can be used to replace submersible designs of pump. Although the pump can be supplied in other lengths, the standard size is between 1.3 and 3.0 m.

Applications:

Vertical, extended tank pump essentially for handling liquids that are either boiling or stored at their vapour pressure. Particularly suited to LPG car filling stations. One of the primary features of this side-channel type of pump is the special suction impeller that requires extremely low levels of NPSH. CEB pumps have been specifically designed for use with liquefied petroleum gas (LPG) and other liquefied gases.

Technical Data:

Volume flow: up to 65 l/min

Differential pressure: up to 15 bar

Speed: max. 2,900 rpm

Temperature: max. 60 °C

Casing pressure: up to 40 bar

Shaft seals: magnetic drive

Materials: nodular iron

Series DRV

Series DRV

Single stage, vertical side channel pump with an open vane wheel impeller. The program comprises 3 sizes. Because of the vertical arrangement of the unit, the floor space requirements are low. If the pipelines are of sufficient stability, the units of this series can even be suspended in the piping system without any foot support.

Applications:

The DRV pumps are used when clear or turbid liquids with an aggressive nature, in varied concentration and temperature ranges and without any abrasive particles, are to be handled reliably and trouble free. The performance curve steepness admits a precise regulation of the pressure with a small change in capacity. Their applications cover the private, professional and industrial fields for example domestic plants and agriculture (feeding spring well fountains, garden and lawn cultivation), trade and industry (handling coolants, sampling and chlorination processes in waterworks, running bottle washing machines, circulating buffer water in big centrifugal pumps), chemical and pharmaceutical industry for laboratory techniques and in the food industry.

Technical Data:

Flow rate: up to 2 m³/h

Head: up to 27 m

Speed: max. 3,600 rpm

Temperature: max. 100 °C

Casing pressure: up to 6 bar

Shaft seals: gland packing, mechanical seal

Materials: grey cast iron, stainless steel