SIHI Side Channel Pumps (in Bare Shaft design)

Side Channel pumps are used for problem-free pumping of clean liquids at unfavorable suction side conditions.

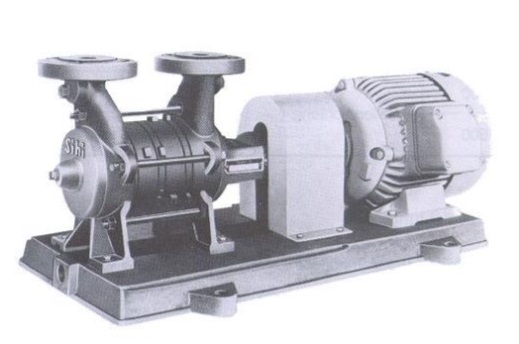

Series CEH-X, CEH

Pumps of the series CEH-X/CEH have a segmental type construction with open vane wheel impellers. The construction of the CEH pump is a so-called centrifugal combined system. This combination pump is suited with a centrifugal stage in serial connection before the side channel stages to obtain a more favourable NPSH.

Applications:

The CEH-X/CEH pumps are used for problem-free pumping of clean liquids at unfavourable suction side conditions. They are also very suitable for positive suction heads below 0.5 m. The different material possibilities with uniform dimensions and performance characteristics as well as the standard exchangeable components, make the CEH particularly recommendable for applications in the pharmaceutical, chemical or petrochemical market as well as in the plastic or oil industry. Because of its low NPSH and positive suction head the CEH-X/CEH is very suitable for the pumping of liquefied gasses and liquids under vapour pressure like condensate, refrigerant, boiler feed water or LPG.

Technical Data:

Flow rate: up to 35 m³/h

Head: up to 354 m

Speed: max. 1800 rpm

Temperature: max. 180 °C

Casing pressure: up to 40 bar

Shaft seals: gland packing, mechanical seal, magnetic coupling

Materials: grey cast iron, nodular iron, stainless steel

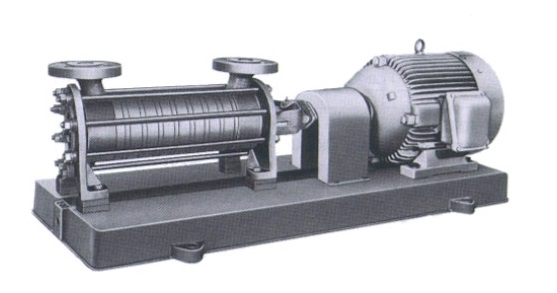

Series AEH-X, AEH

Series AEH-X, AEH

Pumps of the series AEH-X/AEH according to EN 734 have a segmental type construction with open vane wheel impellers. This pump is available in a normal industrial design with one liquid surrounded slide bearing and one ball bearing or in a heavy-duty construction with a double ball bearing design.

Applications:

The AEH-X/AEH pumps were especially developed for difficult applications in all industry sectors and are thus applied when pure, turbid or aggressive media have to be pumped under difficult conditions without any problems. The different material possibilities with uniform dimensions and performance characteristics as well as the standard exchangeable components, make the AEH-X/AEH particularly recommendable as universal pump for all possible pumping problems. This results in a wide application range in many sectors such as chemical industry, petrochemical industry, pharmaceutical industry, OEM, oil industry and food industry.

Technical Data:

Flow rate: up to 35 m³/h

Head: up to 354 m

Speed: max. 1800 rpm

Temperature: max. 180 °C

Casing pressure: up to 40 bar

Shaft seals: gland packing, mechanical seal, magnetic drive

Materials: grey cast iron, nodular iron, stainless steel

Series AKH-X, AKH

Series AKH-X, AKH

Pumps of the series AKH-X/AKH have a segmental type construction with open vane wheel impellers. The pump construction is either with one liquid surrounded slide bearing and one ball bearing or in a more industrial construction by using a double ball bearing design.

Applications:

The AKH-X/AKH is suitable for trouble free handling of clean or turbid liquids without any abrasive particles. The performance curve steepness admits a precise regulation of the pressure with a small change in capacity. The AKH-X/AKH pump has been developed for a broad range of medium duty applications in the chemical industry, petrochemical industry, oil industry, machinery and automobile industry, food industry, building trades, plastic and rubber industry, surface treatment and ship yards.

Technical Data:

Flow rate: up to 35 m³/h

Head: up to 242 m

Speed: max. 1800 rpm

Temperature: max. 120 °C

Casing pressure: up to 25 bar

Shaft seals: gland packing, mechanical seal

Materials: grey cast iron, bronze, stainless steel

Series AOH

Series AOH

Pumps of the series AOH have a segmental type construction with open vane wheel impellers. The program comprises 4 sizes with up to 4 stages for the sizes 1100/1200 and up to 3 stages for the sizes 3100/3600.

Applications:

The AOH is used when clear or turbid liquids without any abrasive particles are to be handled reliably and trouble-free. The performance curve steepness admits a precise regulation of the pressure with a small change in capacity. The AOH is used in domestic plants and agriculture for irrigation, drainage and sprinkling. The AOH is well known in all branches of trade or industry for boosting pressure, cooling water, water circulating, boiler feeding, condensate, cleaning plants and ship yards.

Technical Data:

Flow rate: up to 7.5 m³/h

Head: up to 98 m

Speed: max. 1,800 rpm

Temperature: max. 120 °C

Casing pressure: up to 10 bar

Shaft seals: gland packing

Materials: grey cast iron

Series ASH

Series ASH

Horizontal, self-priming, multi-stage side channel pumps with open vane wheel impellers handling entrained gas during normal duty. A special bearing was developed for compensation of the axial forces occurring in case of high nominal pressures.

Applications:

Pumps of the series ASH were developed for handling liquid gases with vapour pressures of up to 80 bar. The high admissible nominal pressure and the optimum operation properties of the material combinations selected resulted in multiple application of this series, especially for handling carbon dioxide. They are successfully applied in processes and installations for the production, storage and transportation of CO2, in supply plants, measuring, regulation and decanting equipment, fire-extinguishing and inert installations, in CO2 drying and CO2 cleaning plants, for production of dry ice and neutralizing of alkaline waste waters.

Technical Data:

Flow rate: up to 12 m³/h

Head: up to 288 m

Speed: max. 1800 rpm

Temperature: max. 120 °C

Casing pressure: up to 100 bar

Shaft seals: gland packing, mechanical seal

Material: cast steel

The ADH pumps are self-priming side channel pumps capable of handling gas along with the medium and operates at a low noise level. These pumps have a segmental construction with open vane wheel impellers. The ADH series are running at high speed and have been designed with special regard to noiseless running. The program comprises 6 sizes.

Applications:

The ADH series are used to handle clear or turbid liquids, under high heads and without any abrasive particles, reliably and trouble-free. The number of hydraulic stages are as is customary in the boiler industry. The performance curve steepness admits a precise regulation of the pressure with a small change in capacity. The pumps are used in the boiler industry for condensate and boiler feed water handling, for washing, cleaningand spraying plants and for dry cleaning.

Technical Data:

Flow rate: up to 7.2 m³/h

Head: up to 250 m

Speed: max. 3000 rpm

Temperature: max. 120 °C

Casing pressure: up to 25 bar

Shaft seals: gland packing, mechanical seal

Material: grey cast iron