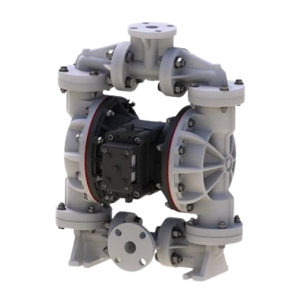

Sandpiper S1F Non-Metallic AODD Pump

Sandpiper’s Non-Metallic AODD Pump, Standard Duty AODD Pump, the S1F

Sandpiper’s Standard Duty AODD Pump, the S1F, is a non-metallic AODD Pump that provides incredible lightweight portability with the versatility to handle both corrosive fluids and small suspended solids. This AODD Pump has proven the test of time as a trusted, class-leading air-operated double-diaphragm (AODD) pump for a variety of markets and applications. The Sandpiper’s 1″ S1F Non-Metallic AODD Pump offers air-side interchangeability with Sandpiper’s S15, S20 and S30 pumps for reduced inventory costs. The durable, bolted construction of the S1F is superior to the clamped-band construction pump, providing exceptional leak-free performance. This pump is designed to be driven by compressed air or nitrogen. Materials of construction options include; Polypropylene, PVDF and Conductive PVDF with elastomer TPE (thermal plastic elastomers) and PTFE options in diaphragms and check valves.

Sandpiper’s S1F Non-Metallic AODD Pump comes with highlighted features that better showcases the functionality of the AODD Pump in its industrial applications;

- Serviceability; The air distribution system (ADS) is one of the most frequently serviced parts of any AODD pump. Only Sandpiper’s ESADS+ feature allows access to the complete ADS without removing the pump from service. Repair or clean in five minutes (versus 55 minutes for competitors).

- Trusted design; Sandpiper’s original ADS is fully interchangeable, repairable, and inline-serviceable. Other manufacturers frequently change ADS designs, creating issues with interchangeability, obsolete inventory and increased cost of ownership.

| Port Size | 1″ ANSI Flange

PN10 25 mm DIN Flange |

| Capacity | 0 to 53 gpm (200 lpm) |

| Air Distribution Valve | No-lube, no-stall design |

| Solids-Handling | Up to ¼” (6 mm) |

| Heads Up To | 100 psi or 231 ft. of water (7 bar or 70 meters) |

| Displacement/Stroke | .19 gallons (.72 liters) |

| Max Operating Pressure | 100 psi (7 bar) |

| Shipping Weight | Polypropylene:

42 lbs (19 kg) PVDF: 54 lbs (24 kg) |

S1F Non-Metallic AODD Pump Service & Operating Manual

S1F Non-Metallic AODD Pump Data Sheet

Need a compact non-metallic pump for corrosive or chemical fluids? Contact us now to explore the Sandpiper S1F or request a customised quote.