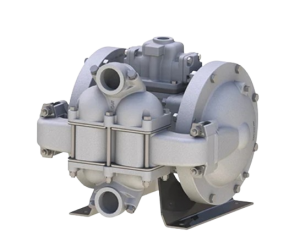

Sandpiper HDB1½ & HDB40 Metallic AODD Pump

Sandpiper HDB1½ & HDB40 Metallic AODD, Heavy Duty Ball Valve Pump

Sandpiper’s AODD Pump, specifically the Heavy Duty Ball Valve Pump (HDB) are the ideal choice for applications that handle a variety of fluids ranging from thin to highly viscous and small-solids laden fluids. It has excellent suction lift capabilities and is designed to withstand the most rugged and harsh ball valve pumping applications. It was designed with thick walls constructed of Sand Casted Aluminum, Cast Iron, Stainless Steel or Alloy C with elastomer, TPE (thermal plastic elastomers) and PTFE options in diaphragms and check valves. The HDB1½ AODD Pump is part of the Sandpiper’s Evolution Portfolio which highlights the pump’s optimization for the maximum amount of flow capacity with the least amount of air/gas consumption. The pump is also available with a side ported option making installation easy, optimizes performance on the pumped fluid and solves critical pumping platforms. As part of the Evolution Portfolio, this pump will continue to be optimized over time to further its potential as an AODD Pump in the future.

These pumps are enhanced with extended-wear packages and are your optimal solution for abrasive-slurry applications. Features include;

- Side-ported option: For use in confined spaces. The ports are positioned with the center of the pump, allowing for installation in smaller and confined spaces.

- Heavy-duty plunger bushings and actuator pins: Designed to withstand severe applications.

- Diaphragm wear pads: Installed between the diaphragm and outer diaphragm plate, providing a secondary wear surface that extends the life of the diaphragm.

- Thicker, more robust wetted castings: Provide extended wear resistance.

- Heavy-duty weighted check valve balls: Are 30%-60% heavier than solid rubber check balls, allowing for more consistent chamber filling.

- Sandpiper’s ESADS+ allows complete access to the main air and pilot valves without removing the pump from service.

- Repair or clean within 5 minutes (versus 55 minutes for competitors)

| Port Size | HDB1 ½:

1½” NPT HDB40: 1½” BSP (Tapered) |

| Capacity | 0 to 122 gpm (462 lpm) |

| Air Valve Distribution | No-lube, no-stall design |

| Solids-Handling | Up to ¼” (6.3 mm) |

| Heads Up To | 125 psi or 289 ft. of water (8.6 bar or 88 meters |

| Displacement/Stroke | .37 gallons (1.4 liters) |

| Max Operating Pressure | 125 psi (8.6 bar) |

| Shipping Weight | Aluminum:

75 lbs (34 kg) Cast Iron: 104 lbs (47 kg) Stainless Steel: 107 lbs (48 kg) |