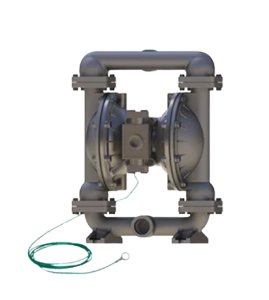

Sandpiper G15 Metallic GODD Pump

Sandpiper’s GODD Pump, Gas-Operated Double-Diaphragm Pump, the G15

Sandpiper’s gas-operated double-diaphragm (GODD) pumps, the G15 has been designed to be accessible to be powered by easily accessible natural gas. The application of AODD Pumps driven by natural gas created a unique set of safety requirements that did not exist prior to its creation. Sandpiper partnered with the Canadian Standards Association (CSA®) to lead the development of the first-ever safety certification for gas-operated double-diaphragm. The inherent danger in this application is the potential for static electricity build up due to material and product movement which the release of these static discharge in these applications could lead to a sparking which in turn could lead into a flash fire and potential explosion. The CSA specification sets standards to prevent static electricity accumulations as well as standards for burst pressure; heat resistance, leakage and upper and lower temperature operation. The pumps are fully ground-able and are constructed of materials compatible with sweet and sour gas; Aluminum or 316 Stainless Steel wetted construction with Nitrile or Virgin PTFE diaphragms and check balls.

Sandpiper’s Metallic GODD Pump, the G15, has a variety of highlighted features that showcases the GODD Pump’s advantages in its industrial applications. Amongst the highlighted features are;

- Safely powered by compressed air or natural gas depending on the application. Dual power capabilities offers simplified purchasing, maintenance and training while reducing inventory.

- Elastomeric seals are compatible with the various chemicals normally expected to be found in sweet and sour gas.

- Every pump is leak-factory tested 150 psi to ensure natural gas emission are properly contained.

- Complies with NACE Standard MR017/ISO15156 for corrosion resistance.

- Constructed to prevent accumulation of static electric charge and fully ground-able to ensure static electricity dissipation (comes standard with attached grounding strap).

- Hydrostatic strength tested pressure to 500 psi (five times the maximum operating pressure, the highest standard in the industry)

- Canadian Technical Letter R-14 requires 500 psi

- ANSI LC6 requires 400 psi

- Hydraulic Institute requires 188 psi

- Sandpiper’s ESADS+ allows complete access to the main air and pilot valves without removing the pump from service. Repair or clean in five minutes (versus 55 minutes for competitors)

| Port Size | 1½” NPT/BSP |

| Capacity | 0 to 106 gpm (401 lpm) |

| Air Distribution Valve | No-lube, no-stall design |

| Solids-Handling | Up to ¼” (6 mm) |

| Heads Up To | 100 psi or 231 ft. of water (7 bar or 70 meters) |

| Displacement/Stroke | .41 gallons (1.55 liters) |

| Max Operating Pressure | 100 psi (7 bar) |

| Shipping Weight | Aluminum:

53 lbs (24 kg) Stainless Steel: 95 lbs (43 kg) |