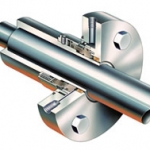

Pusher

The Pac Seal Type 8 & 9 provide high-quality, positively driven, multi-spring pusher style seals for industrial and severe chemical applications. The rotary unit is set screwed to the shaft, for positive drive.

The rotaries feature seal rings which are replaceable. Seats are available in a variety of styles and sizes. Both the Type 8 & 9 are available in narrow cross section (8T & 9T), double seal configurations, and balanced versions.

Replaces: The Pac-Seal Type 8 & 9 are the high quality, versatile replacement alternative for Crane Type 8 & 9 respectively.

Materials: The standard 8 is offered in Viton (o-ring) / Carbon / 316 SS – Kalrez is an available alternative.The standard 9 is offered in Teflon (wedge) / Carbon / 316SS.

-

Pressure: 350 psi / 24 bar (balanced)*

-

Temperature: 500°F / 260°C**

-

Speed: 5000 fpm / 25.4 m/s

-

Sizes: .5” to 4”

Notes:

*34bar/ 500 psi unbalanced

**With graphite wedge up to 750° F or 400° C

Pac-Seal Type 8T & 9T

effective for industrial fluids, chemicals, light hydrocarbons, corrosives and high pressure liquids and gasses

QBQ

QBQ

| Brand | Flowserve |

|---|---|

| Description | High balanced, low emission, light hydrocarbon, same operating limits as QB, specific gravity down to 0.45 with multi-port… |

- Applications:

Petrochemical Processing, Hydrocarbon Processing, Emissions Reduction, Petroleum Production and Refining - Industries:

Caustic and Chlor-Alkali, Waste Processing, Catalytic Cracking, Solvents, Auxiliary, Slurry Processing, Alkylation, Heavy Oil and Upgrading, Acid Transfer, SAGD, Water Injection, Products Pipeline, Water Handling and Treatment, Polymers, Pharmaceuticals, Logistics and Tank Farm, Hydrotreating, Hydrocraking, Distillation, Delayed Coking, Crude Pipeline, Volatile Organic Compounds, Crude Handling and Treatment, Utilities - Standards:

API682

A QB version designed for reversed pressure operation. Fully compliant all requirements of API 682 type A arrangement 3, but with an extended pressure range.

QBQ/GSL

Dual seal configuration with dry-running lift-off containment seal provides near zero emissions and safety backup.

QBQ/GSD

Dry running contacting back-up seal for reliable, long life containment performance in hydrocarbon services.

QB Seal Installation Instructions

Instructions to install Q, QB, QBQ, QBS, QBU, and QBQ LZ

Flowserve Seals – Products and Services Catalog – English

FSD101eng_FSG_Seals_Catalog_Ltr

This products and services brochure is designed to make you familiar with the latest Seal Group products and services.

QBQ LZ

QBQ LZ

| Brand | Flowserve |

|---|---|

| Description | Precision face topography enhances the surface profile and performance of mechanical seal faces |

- Applications:

Petroleum Production and Refining, Petrochemical Processing, Emissions Reduction, Hydrocarbon Processing - Industries:

Volatile Organic Compounds - Standards:

ISO, API682

Reliability and safety are top priorities in hydrocarbon processing plants today with emphasis on profitability and meeting governmental regulations of hydrocarbon emissions.

QBQ LZ Brochure

For light hydrocarbon services with vapor pressure margins down to 5 psi (0.34 bar), the QBQ LZ utilizes Precision Face Topography to increase seal reliability.

QB Seal Installation Instructions

Instructions to install Q, QB, QBQ, QBS, QBU, and QBQ LZ

ISC2 Series

ISC2 Series

| Brand | Flowserve |

|---|---|

| Description | Newest Innovative Standard Cartridge Seals |

- Applications:

Pipeline, Power Generation, Pulp and Paper, Ag-Chem, Synthetics, Bioprocessing, Tank Farm Transfer, Chemical Processing, Toxic Services, Chemical Transfer, Waste Water, Condensate, Water, Fine Chemicals, General Purpose, Hydrocarbon Processing, Inorganic Chemicals, Light Oils, Light Slurries, Organic Chemicals, Petrochemical Processing - Industries:

Agriculture, Chemical and Liquor, Logistics and Tank Farm, Paper Stock, Pharmaceuticals, Products Pipeline, General Industries - Standards:

API682, ASME (ANSI), DIN24960, ISO

The ISC2 Series is a complete family of mechanical seals that provide exceptional reliability and standardization over the widest variety of industrial applications and equipment. ISC2 seals meet all major international standards and are designed for literally hundreds of pump models from global manufacturers. Facilities that standardize with ISC2 seals will immediately benefit from less inventory, greater flexibility, less downtime and longer seal life.

ISC2 seals work hard to eliminate the possible causes of leakage. Our thermal management technology for dry running tolerance, robust seal face drive mechanisms, high-efficiency barrier circulation, rigid setting devices and high quality materials all contribute to improve seal life even with multiple service conditions, off-design operation, and frequent starts and stops. ISC2 seals are capable of sustaining years of uninterrupted, long-term operation.

ISC2 Dual Metal Bellows Repair Instructions

Repair instructions for ISC2 dual metal bellows

ISC2 Single Pusher Repair Instructions

FIS193eng_ISC2_BX_Repair

Repair instructions for ISC2 single pusher

ISC2 Dual Pusher Repair Instructions

Repair instructions for ISC2 dual pusher

ISC2 Single Metal Bellows Repair Instructions

Repair instructions for ISC2 single metal bellows

ISC2-Serie

Innovative Standard-Cartridgedichtung für allgemeine Anwendungen. Montageanleitung für Maschinenbauteile.

Gamme ISC2

FIS190fre_ISC2_Install_A5

Garniture cartouche standard innovante et polyvalente. Instructions de montage pour composants de machine.

Serie ISC2

Cierre de Cartucho Estándar Innovador diseñado para ANSI y aplicaciones de uso general con una máxima versatilidad entre diseños. Instrucciones de instalación para piezas de máquina.

Serie ISC2

Tenuta Innovativa Standard a Cartuccia progettata per applicazioni generali. Istruzioni di montaggio per parti di macchina.

ISC2 Series

Innovative Standard Cartridge seal designed for general purpose applications. Installation Instructions for machinery components

ISC2 Series Brochure

FSD243eng_ISC2_Series_Broch_Ltr

A complete family of mechanical seals that provide exceptional reliability and standardization over the widest variety of industrial applications and equipment.

ISC2 Series Installation Instruction

Innovative Standard Cartridge seal designed for general purpose applications.

Flowserve CRO Pusher Seal

Flowserve’s CRO Pusher Seal is an affordable Pusher Seal featuring a friction drive design with a single coil spring, specifically engineered for use in ANSI chemical pumps with packing box seal chambers. The heavy cross-section and minimal number of components simplify installation and enhance resistance to severe corrosion. With no wetted metals and a shared spring in the double CRO Pusher Seal design, it ensures reliable performance. The Mechanical Seals in the CRO design are readily available off the shelf in standard configurations, making them ideal for a wide range of popular chemical pumps in the market today.

-

Features

- Rotating Seal Ring – Self centers around the shaft. Designed to withstand the harsh physical demands of cyclic operation or continuous duty. Available in a wide range of standard materials.

- Single Coil Spring – Robust spring resists clogging and chemical attack. CRO-P option adds positive rotor drive through a drive collar and pin arrangement.

- Shaft Packing – completely interchangeable materials without changing other components. Available in a wide range of materials for compatibility with process fluids and process temperatures.

- Stationary Insert – Flexibly mounted to precent distortion

- O-Rings – Dimensionally interchangeable for versatility in secondary seal materials selections.

CRO Mechanical Seals Operating Parameters

Pressure Up to 200 bar (300 psi) Temperature CRO: – 40 to 49°C (-40 to 120°F) CRO-P: -40 to 260°C (-40 to 500°F)

Shaft Speed Up to 23 m/s (75 fps) Shaft Sizes 9.5 to 89 mm (0.375 to 3.500 inch) Materials of Construction

Metal Components 316 Stainless Steel, Allot C-276, 20 Stainless Steel Rotating Face Tungsten Carbide, Silicon Carbide, Peramic, Durchorme® Stationary Face Tungsten Carbide, Silicon Carbide, Bronze, Resin Carbon Spring 304, 316, or 20 Stainless Steel, Alloy C-276 or B-2, XM-19 or 17-7 PH Stainless Steel, Titanium, Alloy 400 Gaskets Fluoroelatomer, Buna N, EPDM, Rubber (EPR), Perfluoroelatomer, Neoprene, PTFE

CRO Durametallic Seals Industrial Applications

- General Applications

- Pulp & Paper

- Mining

- Steel & Primary Metals

- Food & Beverage

- Corn Wet Milling & Ethanol

- Other Industries

- Chemicals

- Basic (Organic & Inorganic)

- Specialty (Fine & Consumer)

- Biofuels

- Pharmaceutical

- Water

- Water Management

- Wastewater

- Agriculture & Irrigation

- Flood Control System

- Power

- Conventional Steam

- Geothermal

- Combined Cycle

- Concentrated Solar Power (CSP)

- Biomass & MSW

Configurations

|

|

| CRO | Double CRO |

- Industries:

Slurry Transfer, Slurry Processing, Primary Processing, Polymers, Pharmaceuticals, Leaching Acid, Solvents, Caustic and Chlor-Alkali, Auxiliary, Acid Transfer, Volatile Organic Compounds, Waste Processing, Dewatering & Water Supply - Standards:

DIN24960

Single, tandem or double balanced wavy spring seal cartridge designed according the metric DIN 24960 form C. Each seal face pair uses two 100% identical faces. When used as a double seal the inboard seal is reverse pressurized and therefore very resistant to clogging. This seal is designed specifically for the so-called ‘form C’ part of the DIN standard, and is therefore available only in four sizes.

Allpac 480/487 Brochure

Single, tandem or double, balanced, wavy spring seal, cartridge designed according to DIN 24960 form C

General Installation and Maintenance Instructions

Can be used for the following seal types: Allpac 4 series, Allpace N series, Centipac 1 series, CRO, D series, DHT series, Europac 306, Europac 6 series, FRO, GSD, GSL, HD series, HSC, HSH, LD, P series, Q series, RO, Simpac 3 series, SRO, U series, UHT series, BL, BRC series, BX series, BXH series, BXLS series, BXRH, CBR series, CBS, GSDH, PB, PBR, PBS, PC, X series

- Industries:

Waste Processing, Pharmaceuticals, Water Handling and Treatment, Products Pipeline, Water Injection, SAGD, Acid Transfer, Heavy Oil and Upgrading, Alkylation, Slurry Processing, Auxiliary, Solvents, Catalytic Cracking, Utilities, Caustic and Chlor-Alkali, Crude Handling and Treatment, Crude Pipeline, Delayed Coking, Distillation, Hydrocraking, Hydrotreating, Logistics and Tank Farm, Volatile Organic Compounds, Polymers - Standards:

API682

Single, balanced, multi-spring, pusher seal for general service, primarily applied in the petrochemical and chemical industry. The QB complies fully with all requirements of API 682 type A. Design variations include those mentioned below and customized QBW seals.

QBQ

High balanced, low emission, light hydrocarbon design, same operating limits as QB, specific gravity down to 0.45 with multi-port flush.

QBB

Dual balanced rotating assembly option (QBB) – provides reverse pressure capability for API 682 arrangement 3 requirements

QBU

Lube-groove design for hot water service without extra cooling. Pressure: To 255 psi (17.5 bar), Temperature: To 340°F (170°C)

QBR

Reverse configuration with stationary flexible element

QBQ/GSL

Dual seal configuration with dry-running lift-off containment seal provides near zero emissions and safety backup

QB Series Seal Brochure

Single, balanced, multi-spring, pusher seal for general service

Flowserve Seals – Products and Services Catalog – English

FSD101eng_FSG_Seals_Catalog_Ltr

This products and services brochure is designed to make you familiar with the latest Seal Group products and services.

QB Seal Installation Instructions

Instructions to install Q, QB, QBQ, QBS, QBU, and QBQ LZ

- Industries:

Auxiliary, Caustic and Chlor-Alkali, Pharmaceuticals, Waste Processing, Acid Transfer, Solvents, Volatile Organic Compounds, Polymers, Slurry Processing - Standards:

DIN24960

Single, unbalanced single wavy spring seal designed according the metric DIN 24960 standard to L1k. This seal is applied on a wide range of duties, primarily in the chemical industry where DIN standard pumps are used. Standard face materials according DIN coding focused on:

B resin impregnated carbon

A antimony impregnated carbon

S chrome steel casting

Q self sintered silicon carbide

Europac 610

As above, balanced design needing stepped shaft. Pressure: To 360 psi (25 bar)

Europac 615-lube

As Europac 610, balanced design needing stepped shaft, but using special design lube groove faces for hot-water service without need for cooling. Pressure: To 255 psi (17.5 bar), Temperature: To 340°F (170°F)

Flowserve Seals – Products and Services Catalog – English

FSD101eng_FSG_Seals_Catalog_Ltr

This products and services brochure is designed to make you familiar with the latest Seal Group products and services

- Industries:

Ground Water Development and Irrigation, Solvents, Boiler Feed, HVACI, Waste Processing, Caustic and Chlor-Alkali, Hydraulic Press, Water Supply and Distribution, Chemical and Liquor, Leaching Acid, Water Treatment, Coatings, OEM, Acid Transfer, Construction, Paper Stock, Agriculture, Cooling Water – Metals, Pharmaceuticals, Automotive and Aircraft, Cryogenic, Plating, Galvanizing and Other Coatings, Auxiliary, Desalination, Polymers, Bleach Chemicals, Descaling, Primary Processing, Dewatering & Water Supply, Scale Recycle, Digester, Wastewater Collection and Treatment, Electronics, Slurry Processing, Fire Protection – General Industry, Slurry Transfer, Flood Control, Snowmaking, Food Processing, Volatile Organic Compounds

A simple, proven and rugged design with dependability that has made it a favorite choice of maintenance personnel to seal ANSI chemical pumps. Heavy cross sections of the rotary components resist high levels of corrosion. Utilizing a simple rugged open rotary unit design, aggressive, abrasive and viscous fluids can be sealed easier than with other ANSI seal types that incorporate shrouded spring rotaries. The RO series is available off the shelf in standard configurations for all of the popular chemical pumps offered today.

Flowserve Seals – Products and Services Catalog – English

FSD101eng_FSG_Seals_Catalog_Ltr

Double CRO Installation Instructions

Single Inside Pusher Seal Installation Instructions

Types BPO, BPT, BRO, BRT, PTO, PT, RO, RO-TT

- ndustries:

Waste Processing, Acid Transfer, Desalination, Water Supply and Distribution, Automotive and Aircraft, Construction, Water Treatment, Auxiliary, Cooling Water – Metals, Cryogenic, Bleach Chemicals, HVACI, Coatings, Boiler Feed, Pharmaceuticals, Chemical and Liquor, Caustic and Chlor-Alkali, Plating, Galvanizing and Other Coatings, Descaling, Electronics, Polymers, Ground Water Development and Irrigation, Digester, Primary Processing, Food Processing, Dewatering & Water Supply, Scale Recycle, Flood Control, Wastewater Collection and Treatment, Fire Protection – General Industry, Slurry Processing, OEM, Slurry Transfer, Leaching Acid, Snowmaking, Hydraulic Press, Solvents, Paper Stock, Volatile Organic Compounds, Agriculture

Single, balanced, multi-spring, cartridge, pusher seal specifically designed for pulp & paper slurry services. Unique design exposes seal faces to pumped product for maximum heat dissipation – eliminates a common failure point. Special shroud protects compression springs in a stationary portion of seal, and rotor drive pin, from weepage build-up. Pre-set cartridge design and centering tabs simplify installation.

SL 5200

As above, but in a double back to back arrangement with the outboard faces being the same as the inboard faces.

SL Series Seal Brochure

A family of self contained cartridge seals designed for reliable operation in the majority of chemical and moderate slurry services. Engineered to primarily be applied with no outside flush liquid which eliminates product dilution.

Flowserve Seals – Products and Services Catalog – English

FSD101eng_FSG_Seals_Catalog_Ltr

This products and services brochure is designed to make you familiar with the latest Seal Group products and services.

SL-5000/5200 Cartridge Slurry Seals Installation Instructions

Allpac Slurry Pusher Seals

Allpac Slurry Pusher Seals

| Brand | Flowserve |

|---|---|

| Description |

This is Flowserve’s Corrosive duty seals. Provides economic seal life – low operating and maintenance costs. A single, dual balanced robust yet simple slurry with low operation and maintenance costs. |

Internally mounted, double balanced, single mechanical seal, available in two versions:

- Balanced, closing from the product side (Allpac 480)

- Unbalanced, closing from the atmospheric side (Allpac 487)

The springs are stationery and outside the pumped medium, which makes the High-performance slurry seal for corrosive applications very suitable for slurry applications.

-

High-pressure slurry seals Features

- Springs outside the product avoid clogging

- Faces are made from silicon carbide

- Large clearances between seal and shaft sleeve

- Robust construction

- Metal-free design optional

- Single and dual seal designs available

- Cartridge and component designs available

- Single and multiple spring designs available

Available Configurations

Allpac 480 Balanced, multiple spring, single cartridge seal Allpac 481 Balanced, single spring, single cartridge seal Allpac 482 Balanced, Super X wave spring, single cartridge seal Allpac 483 Balanced, multiple spring, single component seal Allpac 486 Balanced, multiple spring, ID-pressurized, dual cartridge seal Allpac 427 Unbalanced, multiple spring, dual cartridge seal Allpac N-2000 DIN/ISO standard balanced, multiple spring, dual cartridge seal Allpac N DIN 24960 form C standard balanced, multiple spring, dual component seal; available in four sizes only. Operating Parameters

Pressures to 50 bar (725 psi) Temperatures from -40°C to 220°C (-40°F to 430°F) Speeds to 50 m/s (164 fps)

Industries that suit Slurry Seals Mechanical Seal

- General Industries

- Pulp & Paper

- Mining

- Steel and Primary Metals

- Food & Beverage

- Corn Wet Milling & Ethanol

- Other Industries

- Chemicals

- Basic (Organic & Inorganic)

- Specialty (Fine & Consumer)

- Biofuels

- Pharmaceutical

- Petrochemicals

- Water

- Water Management

- Wastewater

- Agriculture & Irrigation

- Flood Control System

- Oil & Gas

- Upstream Exploration & Production

- Downstream Processing

QBU

QBU

| Brand | Flowserve |

|---|---|

| Description | Lube-groove pusher design for hot water services without extra cooling |

- ndustries:

Cooling Systems, Crude Handling and Treatment, Condensate Systems, Water Injection, Condensate Systems, Utilities, Catalytic Cracking, Steam Systems, Boiler Feedwater Systems, Steam Systems, Boiler Feedwater Systems, Heavy Oil and Upgrading, Boiler Circulation Systems, SAGD, Boiler Circulation Systems, Miscellaneous Services, Water Handling and Treatment, Logistics and Tank Farm, Alkylation, Hydrotreating, Hydrocraking, Distillation, Delayed Coking, Cooling Systems - Standards:

API682

The QBU groove seal is a single pusher seal designed specifically for hot water services where cooling water is not available. Pre-engineered for moderate pressure boiler feed and boiler circulation pumps with higher reliability and longer life than conventional seals.

QBQ

High balanced, low emission, light hydrocarbon design, same operating limits as QB, specific gravity’s down to 0.45 with multi-port flush.

QB Series Seal Brochure

Single, balanced, multi-spring, pusher seal for general service

Flowserve Seals – Products and Services Catalog – English

FSD101eng_FSG_Seals_Catalog_Ltr

This products and services brochure is designed to make you familiar with the latest Seal Group products and services.

QB Seal Installation Instructions

- Industries:

Polymers, Desalination, Descaling, Primary Processing, Dewatering & Water Supply, Scale Recycle, Digester, Wastewater Collection and Treatment, Electronics, Slurry Processing, Fire Protection – General Industry, Slurry Transfer, Flood Control, Snowmaking, Food Processing, Solvents, Ground Water Development and Irrigation, Volatile Organic Compounds, Boiler Feed, HVACI, Waste Processing, Caustic and Chlor-Alkali, Hydraulic Press, Water Supply and Distribution, Chemical and Liquor, Leaching Acid, Water Treatment, Coatings, OEM, Acid Transfer, Construction, Paper Stock, Agriculture, Cooling Water – Metals, Pharmaceuticals, Automotive and Aircraft, Cryogenic, Plating, Galvanizing and Other Coatings, Auxiliary, Bleach Chemicals - Standards:

ASME (ANSI), ISO

Single, stationary spring, pusher seal in modular cartridge design, with parts interchangeable with other ISC versions. The springs are outside the product for reduced corrosion. The carbon and silicon carbide cross sections are optimized for stable performance. Available in a wide range of materials. Suitable for most common ANSI standard bore, ANSI enlarged bore and DIN standard chemical pumps.

ISC Single Pusher Repair

ISC Series Seal Installation Instructions

letter size

ISC Series Seal Brochure

Designed for general purpose applications on ANSI and DIN process pumps serving chemical processing, pulp and paper, oil and refining, food and beverage, water and wastewater, and other industries

- Industries:

OEM, Water Treatment, Paper Stock, Construction, Pharmaceuticals, Coatings, Cryogenic, Plating, Galvanizing and Other Coatings, Chemical and Liquor, Desalination, Polymers, Caustic and Chlor-Alkali, Descaling, Primary Processing, Boiler Feed, Dewatering & Water Supply, Scale Recycle, Bleach Chemicals, Digester, Wastewater Collection and Treatment, Auxiliary, Electronics, Slurry Processing, Automotive and Aircraft, Fire Protection – General Industry, Slurry Transfer, Agriculture, Flood Control, Snowmaking, Acid Transfer, Food Processing, Solvents, Ground Water Development and Irrigation, Volatile Organic Compounds, HVACI, Waste Processing, Hydraulic Press, Water Supply and Distribution, Leaching Acid, Cooling Water – Metals

A single balanced seal designed to mount outside the seal chamber. Single, outside mounted, pusher seal used in applications where pressures above 15 psi/1bar eliminate the usage of the RO seal. No wetted metal parts (RA-C) reduce seal costs for highly corrosive services, especially on non-metallic pumps. The RA version features a two piece rotary collar and seal ring unit.

RA/RA-C Seal Brochure

Single, outside mounted, pusher seal used in strongly corrosive applications

- Industries:

Distillation, Delayed Coking, Hydrocraking, Boiler Circulation Systems, Hydrotreating, Water Injection, Logistics and Tank Farm, Water Handling and Treatment, Miscellaneous Services, Boiler Circulation Systems, Products Pipeline, Boiler Feedwater Systems, SAGD, Boiler Feedwater Systems, Heavy Oil and Upgrading, Catalytic Cracking, Steam Systems, Condensate Systems, Steam Systems, Condensate Systems, Utilities, Cooling Systems, Cooling Systems, Crude Handling and Treatment, Crude Pipeline, Alkylation - Standards:

API682

The UC seal is designed for corrosive/non-corrosive high pressure services with a specific gravity of .45 or higher. The canned “UC” seal design incorporates all of the same rugged high pressure design features as our standard “U” seal while incorporating a state-of-the-art encapsulated graphite gasketed silicon carbide rotating face. The UC seal’s canned face design provides optimum low level emissions control.

UCQ

High Balanced loe emission light hydrocarbon design, same operating limits as UC, specific gravities down to 0.45 with multi-port flush.

UOP

As above, with 4-piece rotating face and high pressure stationary face, Pressure: To 1500 psi (103.4 bar).

UC Series Seal Brochure

Single pusher seal for heavy duty applications and general services

U Series Installation Instruction

Installation Instructions for the U, UC, UO, UCQ, UOP, UOPQ, UZ

- Industries:

Caustic and Chlor-Alkali, Auxiliary, Polymers, Waste Processing, Pharmaceuticals, Solvents, Slurry Processing, Acid Transfer, Volatile Organic Compounds - Standards:

ISO, ASME (ANSI)

Dual, stationary spring, pusher seal in modular cartridge design, with parts interchangeable with other ISC versions. The seals are arranged in tandem configuration, but are double balanced to allow both pressurized and unpressurized operation. Unique high efficiency standard pumping feature allows cooler seal operation for increased reliability. Available in a wide range of materials. Suitable for most common ANSI standard bore, ANSI enlarged bore and DIN standard chemical pumps.

ISC Series Seal Installation Instructions

letter size

ISC Series Seal Brochure

Designed for general purpose applications on ANSI and DIN process pumps serving chemical processing, pulp and paper, oil and refining, food and beverage, water and wastewater, and other industries

ISC Dual Pusher Seal Repair

D

D

| Brand | Flowserve |

|---|---|

| Description | Dual Pusher Cartridge Seal ISC2PP |

- Industries:

Hydrotreating, Boiler Circulation Systems, Hydrocraking, Boiler Feedwater Systems, Distillation, Catalytic Cracking, Delayed Coking, Condensate Systems, Crude Pipeline, Condensate Systems, Crude Handling and Treatment, Cooling Systems, SAGD, Cooling Systems, Heavy Oil and Upgrading, Steam Systems, Steam Systems, Utilities, Water Handling and Treatment, Water Injection, Boiler Circulation Systems, Alkylation, Miscellaneous Services, Products Pipeline, Logistics and Tank Farm, Boiler Feedwater Systems

D Series Seal Brochure

Single, balanced, rotating, single spring seal for the power industry or other high pressure applications