Alfa Laval Pressure Instruments

Alfa Laval Pressure Transmitter

Alfa Laval Pressure Transmitter

Pressure transmitters provide accurate, reliable indication of pressure. These pressure measurement devices are suitable for use in filtration and pump systems, pressure vessels, valve matrices and other hygienic and pharmaceutical process equipment.

Related Industries:

Food and beverage, Home and Personal care

High precision pressure measurement

Alfa Laval pressure transmitters are accurate measuring devices that indicate pressure in hygiene process equipment and systems. These IP67 protected pressure transmitters are ideal for use in the brewery, food and beverage, personal care and pharmaceutical industries.

Fast, accurate performance

Engineered for long-term stability and high overload capacity, Alfa Laval pressure transmitters maintain accurate performance and have a response time of <10 ms. These pressure transmitters provide a <=0.35% FS accuracy for nominal pressure lower than 0.4 bar and a <=0.5% FS accuracy for nominal pressure greater than or equal to 0.4 bar. An optional version that provides a <=0.1% FS accuracy is available for nominal pressure lower than 0.4 bar.

Pressure transmitter range

Standard Alfa Laval pressure transmitters cover 10 different measuring ranges with pressures between -1 and 40 and integrated temperature compensation from 0 to +70°C (+32 to 158°F).

These pressure measurement devices are suitable for use with all media that are compatible with AISI 316L stainless steel and feature 4-20 mA output signals (two- or three-wire). The hygienic process connection is flushable and filled with FDA-approved silicone oil. The pressure transmitter can be delivered either with clamps DN 38 (ISO2852) / DN 40 (DIN32676) or with clamps DN 50 (ISO2852) / DN 51 (DIN32676).

To handle high media temperatures up to 300°C (572°F), an optional cooling element is available. The Alfa Laval pressure transmitter is also available in an ATEX-approved version that is suitable for use in potentially explosive areas (zone 0 or 1).

Operating principle

The Alfa Laval pressure transmitter is an analogue pressure sensor that uses the piezoresistive effect to measure pressure. Made of stainless steel, the piezoresistive pressure transmitter provides pressure measurement with an accuracy of up to 0.1 % FSO (IEC 60770), thanks to its small temperature effect and excellent linearity.

Application

The Alfa Laval pressure transmitter is designed to fulfil the demands of pressure measurement in sanitary and pharmaceutical production. It is suitable in filtration systems, pump systems, pressure vessels, valve matrixes etc. The main features are:

- Long Term stability

- High overload capacity

- Good accuracy, 0.35 % of FS

- 4-20 mA output (3 or 2 wire)

Standard range

The Alfa Laval pressure transmitter range can be used with all media that are compatible with stainless steel W 1.4435 (AISI 316L). For usage with high media temperature a cooling element can be added thus media temperatures up to 300° C can be achieved. The flushable process connection is oil filled with FDA approved oil.

Alfa Laval Pressure Gauge

Alfa Laval Pressure Gauge

Alfa Laval pressure gauges provide accurate and reliable indication of internal pressure in vessels and systems used in the dairy, food and beverage and biopharm industries.

Related Industries:

Food and beverage, Home and Personal care

Accurate pressure measurement

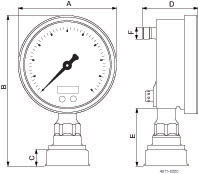

Equipped with easy-to-read, 80 or 100 mm-diameter dials, these Alfa Laval pressure gauges are mechanical pressure-measuring indicators that cover a range of between -1 and 40 bar and process temperatures up to 200°C. A built-in volume compensator and a relief plug contribute to measurement accuracy.

Robust pressure gauge design

Manufactured from robust, resilient materials, standard Alfa Laval liquid-filled pressure gauges are cased in 304 stainless steel housing. All product-wetted parts as well as the clamp connection and diaphragm are made of acid-resistant, 316 stainless steel.

Operating principle

Alfa Laval pressure gauges measure pressure by means of the Bourdon principle. Silicone oil is used as the medium to convert the pressure applied to the diaphragm to a Bourdon tube. The Bourdon tube is in mechanical contact with the indicating needle and turns the needle on the pressure dial of the gauge to present the pressure measurement.

Options

- Electropolished surface finish

- Calibration-, 3A-, and 3.1 certificate

- U.S. Food and Drug Administration Declaration of Conformity

- Bar / KPa / Psi scale

Application

The Alfa Laval pressure gauge is designed to fulfil the demands of pressure gauges in Sanitary and pharmaceutical production. It is suitable as a local indicator in filtration systems, pump system pressure vessels etc.

Features:

- Wetted parts in acid-proof, stainless steel.

Measuring range

- -1 to 60 bar. Process temperature up to 200°C.

Working principle

The pressure gauge working principle is build on the Bourdon principle where pressure applied on the diaphragm is transmitted via silicone oil to a bourdon tube which is in mechanical contact with the dial, and thus indicates the pressure applied on the diaphragm.

Standard range

Our standard range is supplied with a liquid-filled housing. It includes a 100 mm dial diameter and a built-in volume compensator and relief plug. The housing is made of stainless steel (AISI 304) and the clamp connection and pressure sensor are made of stainless steel (AISI 316L).

[/one_half]

Alfa Laval Electrical Pressure Gauge

Alfa Laval Electrical Pressure Gauge

The Alfa Laval Electrical Pressure Gauge ensures accurate and reliable pressure measurement with electrical output capabilities. It meets the needs for pressure indication in hygienic systems used in the food, dairy and biopharma industries.

Related Industries:

Food and beverage, Agriculture Processing

Accurate, reliable pressure indication

The Alfa Laval Electrical Pressure Gauge measures pressure precisely while sending electrical signals. It meets hygiene standards for pressure indication in food, beverage, brewing and pharmaceutical industries. Features include a DN38 connection, a 350° rotatable scale for flexible mounting, and an adjustable pressure switch. It also includes an analogue output (4–20 mA), built-in push buttons, and a digital display for easy configuration.

Analogue and digital displays

This pressure gauge features both analogue and digital displays for real-time system pressure monitoring. The analogue display includes a pointer and circular scale in bar and kPa. The digital display, integrated with an LED ring, provides quick and precise readings of:

- Current system pressure

- Parameters and parameter values

- Set point and reset point

- Pressure trends (rising/falling)

- Maximum/minimum pressure values

- Pressure pulsation and pressure peaks

Standard and custom output

The Alfa Laval Electrical Pressure Gauge has two configurable output signals. Users can adjust settings using the two touch buttons and digital display to customize analogue and digital outputs. This allows for use in basic pressure monitoring and advanced functions such as pressure switch control and pump monitoring.

Operating principle

The Alfa Laval Electrical Pressure Gauge features a ceramic pressure sensor combined with a metal diaphragm, ensuring a secure and hygienic process connection. A built-in microprocessor manages an intelligent scale, controlling the LED ring, output signals and dial movement. The rotatable dial, certified to IP69K, provides a completely sealed and durable interface for long-term use.

Application

The Alfa Laval Electrical Pressure Gauge (EPG) is designed for hygienic environments requiring precise pressure indication with electrical output capabilities. Key features include:

- 350° turnable scale for alternative mounting

- Adjustable pressure switch

- Analogue output (4-20 mA)

- LED indicator embedded in scale

- Pressure pulsation and trend monitoring

- Integrated push buttons and digital display for easy setup

Technical Data

Accuracy: Class 0.5 (±0.5% of FS)

Protection class: IP67

Measuring Ranges

-1 to 1.5 bar | 0 to 2.5 bar | -1 to 3 bar | 0 to 4 bar | 0 to 6 bar | 0 to 10 bar | 0 to 16 bar | 0 to 40 bar

Electrical Data

Power Supply: 18-36 Vdc | Power Consumption: < 70 mA

Electrical Connection: 4-pin M12 plug | Max Output Current: 50 mA

Certificates

- 3.1 certificate (option)

- FDA conformity declaration (option)

- Calibration Certificate (4 points) (option)