OEM & Special Duty

Original Equipment Manufacturers (OEM’s) are very important for Flowserve FSD. Therefore Flowserve is committed to develop and supply designs for special equipment and for special duty requirements.

PSS III

PSS III

| Brand | Flowserve |

|---|---|

| Description | Split, single semi-cartridge pusher seal for pumps and mixers in non-hazardous applications. |

- Applications:

Chemical Processing, Power Generation, Chemical Transfer, Mineral Processing, Pulp and Paper - Industries:

Paper Stock

The ultimate semi-cartridge split seal for pumps and mixer applications. The four piece unitized design allows for one person installation capability. All components are self contained eliminating equipment measurements small parts handling and the potential for lost parts. The improved design makes installation easy while capable of high pressure operation. The PSS III is ideally suited for pulp and paper, general chemical, wastewater treatment, municipal water, power generation and mineral and ore processing industries.

GW / BAW

| Brand | Flowserve |

|---|---|

| Description | Standard pusher for integrally geared API pumps and compressors |

Standard conventional liquid mechanical seals used in integrally geared API pumps and compressors including high speed and high pressure services.

- Industries:

Waste Processing, Plating, Galvanizing and Other Coatings, Polymers, Water Supply and Distribution, Descaling, Primary Processing, Water Treatment, Dewatering & Water Supply, Scale Recycle, Slurry Transfer, Digester, Acid Transfer, Electronics, Agriculture, Fire Protection – General Industry, Automotive and Aircraft, Flood Control, Auxiliary, Food Processing, Bleach Chemicals, Ground Water Development and Irrigation, Boiler Feed, HVACI, Caustic and Chlor-Alkali, Hydraulic Press, Slurry Processing, Chemical and Liquor, Leaching Acid, Wastewater Collection and Treatment, Coatings, OEM, Snowmaking, Construction, Paper Stock, Solvents, Cooling Water – Metals, Pharmaceuticals, Volatile Organic Compounds, Cryogenic, Desalination

A split seal with only two components simplifies seal installation without requiring equipment teardown. Semi-cartridge rotating and stationary assemblies eliminate equipment measurements and handling of small components including seal faces and gaskets. The PSS II is suited for general chemical industry, pulp and paper, wastewater treatment, power generation, and mining services.

PSS II Brochure

A split seal with only two components, allows for installation without equipment tear down.

PSS II Repair Instruction

GSS / GLS OEM & Special Duty Seal

GSS / GLS OEM & Special Duty Seal

| Brand | Flowserve |

|---|---|

| Description | High duty pusher for integrally geared API pumps and compressors |

- Applications:

OEM - Industries:

Distillation, Delayed Coking, Hydrotreating, Logistics and Tank Farm, Products Pipeline, SAGD, Heavy Oil and Upgrading, Utilities, Water Handling and Treatment, Catalytic Cracking, Alkylation, Water Injection, Crude Handling and Treatment, Crude Pipeline, Hydrocraking

Gas lubricated wavy face non-contacting pusher seal with contained silicon carbide face. Finite element analyzed for lowest face deformation to achieve a wide operating window with highest reliability and low leakage. Also available with springloaded PTFE dynamic gaskets.

GLS

As above, for liquid operation.

GLS, GSS, and GSG Seal Brochure

Seals for integerally geared API pumps and compressors

DHTW / UHTW OEM & Special Duty Seal

DHTW / UHTW OEM & Special Duty Seal

| Brand | Flowserve |

|---|---|

| Description | Designed for the Power Industry, the DHTW seal has the ability to survive low or lost suction conditions for short time frames. |

- Applications:

Boiler Feed - Industries:

Water Handling and Treatment, Utilities, Boiler Circulation Systems, Crude Handling and Treatment, Crude Pipeline, Delayed Coking, Distillation, Hydrocraking, Hydrotreating, Alkylation, Logistics and Tank Farm, Water Injection, Miscellaneous Services, Products Pipeline, Boiler Feedwater Systems, SAGD, Heavy Oil and Upgrading, Catalytic Cracking, Steam Systems, Condensate Systems, Cooling Systems

Balanced, stationary multi-spring seal, designed for power industry or other high pressure/high speed applications. Using an API Plan 23 system, this seal is used in hot applications. This seal is always carefully analyzed and tuned for balance and low face deformation for critical applications. Today’s power generation plants are increasing the need for higher parameter mechanical seals for boiler feed and boiler circulating pumps. Flowserve’s DHTW has “hot standby” capability and the ability to survive low or lost suction conditions for short time frames which are important requirements in the power industry.

UHTW As DHTW, without pumping device.

DHTW Seal Brochure

Balanced, stationary multi-spring seal, designed for the power industry or other high pressure/high speed applications

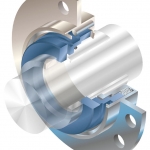

GLS, GSS and GSG

GLS, GSS and GSG

| Brand | Flowserve |

|---|---|

| Description | High duty pusher for integrally geared API pumps and compressors |

Gas lubricated wavy face non-contacting pusher seal with contained silicon carbide face. Finite element analyzed for lowest face deformation to achieve a wide operating window

with highest reliability and low leakage. Also available with springloaded PTFE dynamic gaskets.

GLS As above, for liquid operation.

GLS, GSS, and GSG Seal Brochure

Seals for integerally geared API pumps and compressors

LS-300

LS-300

| Brand | Flowserve |

|---|---|

| Description | Cartridge multiple dynamic lip seal for highly viscous applications |

- Industries:

Pharmaceuticals, Caustic and Chlor-Alkali, Auxiliary, Acid Transfer, Polymers, Solvents, Volatile Organic Compounds, Waste Processing, Slurry Processing

Cartridge Multiple Dynamic Lip Seal for Highly Viscous Applications. Designed to run dry without the need for an external flush or lubricating barrier fluid which can contaminate or dilute the process media. Preset cartridge design speeds installation and reduces the chance for installation error. Easily field repairable with optional repair kit.

Viscosity Range: 400 to 60.000 SSU / 80 cP to 12000 cP (for higher viscosity, contact factory)

LS-300 Seal Brochure

Cartridge multiple dynamic lip seal design for highly viscous applications in positive displacement style pumps

LS-300 Seal Installation Instructions

HSC / HSH

HSC / HSH

| Brand | Flowserve |

|---|---|

| Description | For high pressure, high speed rotating equipment |

- Applications:

Boiler Circulation, Boiler Feed Booster, OEM, Oil Production, Pipeline, Pipeline Booster - Industries:

Heavy Oil and Upgrading, Hydrocraking, Alkylation, Hydrotreating, Boiler Circulation Systems, Logistics and Tank Farm, Boiler Circulation Systems, Miscellaneous Services, Boiler Feedwater Systems, Products Pipeline, Boiler Feedwater Systems, SAGD, Catalytic Cracking, Steam Systems, Condensate Systems, Steam Systems, Condensate Systems, Utilities, Cooling Systems, Water Handling and Treatment, Cooling Systems, Water Injection, Crude Handling and Treatment, Crude Pipeline, Delayed Coking, Distillation - Misc:

High Speed, High Temp, High Pressure

For high pressure and high speed rotating equipment. Where reliability and long life are a must in boiler feed, boiler circulation, oil field injection, and pipeline services.

Balanced, flexible stator, multi-spring pusher design for use in high pressure high speed applications. This seal is boundary lubricated for long seal life.

HSH

As HSC for when solids are present.

HSH Seal Brochure

Balanced, flexible element, multi-spring pusher design for use in high pressure, high speed applications