Mixer

In chemical, pharmaceutical, food and oil refinery process plants diverse systems are employed for agitating, blending and mixing products. The units require low maintenance operation and safety, both to protect the environment and the workplace.

- Industries:

Acid Transfer, Auxiliary, Caustic and Chlor-Alkali, Pharmaceuticals, Polymers, Slurry Processing, Solvents, Volatile Organic Compounds, Waste Processing - Standards:

APGS, DIN28138

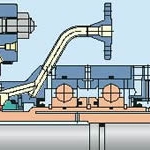

The modular ML DIN is based on the DIN standard, and uses the M-series basic seals to be configured to operate wet, dry or with the latest non-contacting gas barrier technology by changing out the faces. The ML-200 DIN EB uses the non-contacting gas barrier faces, incorporates a bearing (B) and is designed for steel glass-lined vessels (E). The ML-200 DIN SB is designed for steel vessels (S), and incorporates a bearing (B), where the ML-200 DIN S is without bearing.

MW-200 DIN

As above, liquid lubricated, Pressure: To 230 psi / 16 bar, Temperature: To 500°F / 260°C.

MD-200 DIN

As above, contacting gas barrier, self-lubricating

M-Series Seal Brochure

Cartridge mixer seal configured to operate wet, dry or with non-contacting barrier technology that are easily converted from one design to another

MD-200 Seal Installation Instructions

MW-200 Seal Installation Instructions

- Industries:

Volatile Organic Compounds, Solvents, Acid Transfer, Caustic and Chlor-Alkali, Auxiliary, Polymers, Slurry Processing, Waste Processing, Pharmaceuticals - Standards:

APGS

Conditioned Gas Dual Cartridge Canister Seal for Mixers and Agitators. MD-200 contacting gas barrier dry-running design. Dry-running for minimized product contamination from barrier fluid. Requires no cooling. Features self-lubricating faces. Utilizes carbon vs. peramic face materials.

M-Series Seal Brochure

Cartridge mixer seal configured to operate wet, dry or with non-contacting barrier technology that are easily converted from one design to another

MD-200 Seal Installation Instructions

- Industries:

Cooling Systems, Slurry Processing, Slurry Transfer, Cooling Systems, Hydrotreating, Solvents, Automotive and Aircraft, Cooling Water – Metals, Leaching Acid, Aerospace, Alkylation, Crude Handling and Treatment, Logistics and Tank Farm, Steam Systems, Boiler Circulation Systems, Crude Pipeline, Miscellaneous Services, Steam Systems, Boiler Circulation Systems, Cryogenic, OEM, Utilities, Boiler Feedwater Systems, Delayed Coking, Paper Stock, Volatile Organic Compounds, Boiler Feedwater Systems, Descaling, Pharmaceuticals, Waste Processing, Bleach Chemicals, Dewatering & Water Supply, Plating, Galvanizing and Other Coatings, Water Handling and Treatment, Catalytic Cracking, Digester, Polymers, Water Injection, Caustic and Chlor-Alkali, Distillation, Primary Processing, Acid Transfer, Condensate Systems, Electronics, Products Pipeline, Agriculture, Condensate Systems, Fire Protection – General Industry, SAGD, Auxiliary, Chemical and Liquor, Food Processing, Scale Recycle, Coatings, HVACI, Heavy Oil and Upgrading, Construction, Hydrocraking, Hydraulic Press

Focused seal designs to meet the most specific application requirements. In many cases the equipment to be sealed is custom engineered, which requires special sealing solutions. Flowserve FSD has a dedicated team of mixer seal engineers who are able to design a mixer seal to handle special requirements, such as large axial and radial movements, large sizes, high pressures, high temperatures. Existing basic seal parts are used as much as possible, but new designs can be made if necessary.

Flowserve Seals – Products and Services Catalog – English

FSD101eng_FSG_Seals_Catalog_Ltr

This products and services brochure is designed to make you familiar with the latest Seal Group products and services.

2560 Series Mixer Seal

2560 Series Mixer Seal

| Brand | Flowserve |

|---|---|

| Description | Standard DIN sterile double (with/without bearing) |

- Industries:

Pharmaceuticals, Polymers, Slurry Processing, Solvents, Volatile Organic Compounds, Chemical and Liquor, Acid Transfer, Agriculture, Auxiliary, Bleach Chemicals, Caustic and Chlor-Alkali, Waste Processing - Standards:

DIN28138

The modular 2560 series is based on the DIN standard, and uses the standard liquid seal components. The 2564 contains a double liquid lubricated seal, incorporates a bearing and is designed for steel vessels. 2561-2566 As above, single/double executions, with/without bearing and easy to clean design (double seal). Single and cleanable seals have reduced pressure, speed and temperature limits. Designed for steel vessels.

Single or double liquid lubricated mixer seals designed for op entry agitators. The 2561-2562 are single seals available with bearing (2562) or without bearing (2561). The 2563-2566 are double seals also available with bearing (2564/2566) or

- Industries:

Acid Transfer, Auxiliary, Caustic and Chlor-Alkali, Pharmaceuticals, Polymers, Slurry Processing, Solvents, Volatile Organic Compounds, Waste Processing - Standards:

APGS

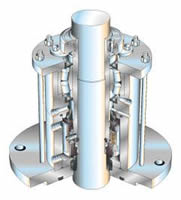

ML-200 uses today’s most advanced non-contacting gas barrier technology. A true zero emissions seal – there’s no product contamination. Ideal for today’s most demanding pharmaceutical and chemical processing applications. Operates with a simple gas barrier auxiliary system. Easy to install and maintain. Exclusive face pattern provides both hydrostatic and hydrodynamic lifts. Seal faces lift off and separate under static pressure regardless of peripheral speed. Face groove pattern optimizes lift capabilities, ensures maximum gas film stiffness. Completely eliminates seal face contact and wear. Utilizes carbon vs. silicon carbide face materials.

M-Series Seal Brochure

Cartridge mixer seal configured to operate wet, dry or with non-contacting barrier technology that are easily converted from one design to another

ML-200 Gas Barrier – Pharmaceutical Ready

Pharmaceutical Ready ML-200 Gas Barrier Non-contacting Mixer Seal FTA131

- Industries:

Flood Control, Automotive and Aircraft, Food Processing, Bleach Chemicals, Ground Water Development and Irrigation, Boiler Feed, HVACI, Caustic and Chlor-Alkali, Hydraulic Press, Chemical and Liquor, Leaching Acid, Acid Transfer, Coatings, OEM, Agriculture, Construction, Paper Stock, Water Treatment, Cooling Water – Metals, Pharmaceuticals, Water Supply and Distribution, Cryogenic, Plating, Galvanizing and Other Coatings, Waste Processing, Desalination, Polymers, Volatile Organic Compounds, Descaling, Primary Processing, Solvents, Dewatering & Water Supply, Scale Recycle, Snowmaking, Digester, Wastewater Collection and Treatment, Slurry Transfer, Electronics, Slurry Processing, Fire Protection – General Industry, Auxiliary

For piloted and Non-piloted models. Split, single outside seal designed for use on large, heavy or inaccessible equipment where seal changeout is costly or prohibitive. Split design facilitates installation without dismantling the equipment. Self-lubricating faces dissipate heat and can be run dry. Also, withstands pressure reversals common to agitator services. Very easy to install and maintain. Runouts to 0.150″ TIR (3.8mm). Non-metallic wetted parts.

MSS Seal Brochure

Split, single, outside, mixer seal for large, heavy or inaccessible equipment

VRA

VRA

| Brand | Flowserve |

|---|---|

| Description | Outside balanced seal designed to operate under relatively high pressures and low speeds |

- Industries:

Acid Transfer, Auxiliary, Caustic and Chlor-Alkali, Pharmaceuticals, Polymers, Slurry Processing, Solvents, Volatile Organic Compounds, Waste Processing

Outside balanced seals designed to operate under relatively high pressures and low speeds. Single, outside, dry-running pusher seal designed specifically for use in top-entry agitator/mixer services. This seal’s heavy-duty construction accommodates a combined out-of-concentricity and eccentricity of 0.150″ TIR (3.8mm). The contacting dry-running design eliminates need for buffer fluid system. Milled slots and mating pins in the drive collar evenly distribute torque to the faces to eliminate stress areas.

VRA-C

Non-metallic collar option provides superior chemical resistance – designated the VRA-C, a two-piece collar design eliminates the need fo

VRA Seal Brochure

Single, outside, dry-running pusher seal designed specifically for use in top-entry agitator/mixer services

VRA & VRA-C Seal Installation Instruction

- Industries:

Pharmaceuticals, Polymers, Slurry Processing, Solvents, Volatile Organic Compounds, Waste Processing, Acid Transfer, Auxiliary, Caustic and Chlor-Alkali - Standards:

APGS

Liquid lubricated dual cartridge canister seal for mixers and agitators MW-200 liquid lubricated design. Cooling coil options available. Maximum operating vessel temperature 500°F (260°C). Utilizes carbon vs. silicon carbide face materials.

M-Series Seal Brochure

Cartridge mixer seal configured to operate wet, dry or with non-contacting barrier technology that are easily converted from one design to another