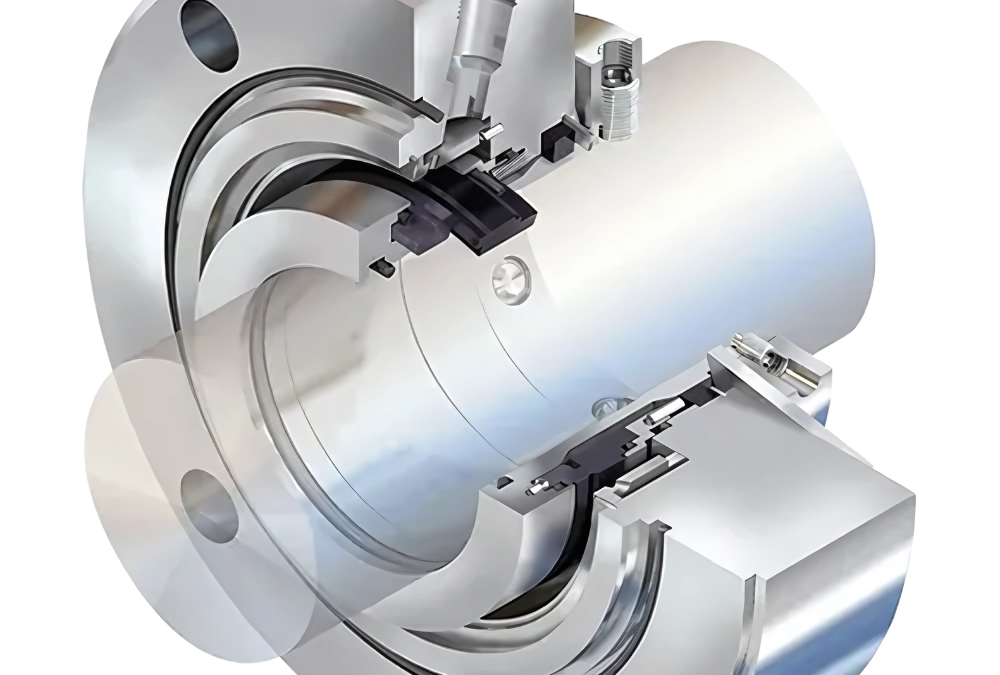

ISC2 682 Standard Cartridge Seal

IntroductionFeatureDocumentation

ISC2 682 Standard Cartridge Seal

ISC2 682 Standard Cartridge Seal

The ISC2 682 Series is a collection of balanced pusher and metal bellows seals that completely meet API 682’s design and qualification standards. Platform flexibility enables use in a variety of services across refineries, petrochemical facilities, and other industries where the API 682 specification is used. ISC2 682 seals fully meet API 682, Type A and Type B specifications.

ISC2 682 Mechanical Seal Applications

- Chemical

- Petrochemical

- Corn processing

- Biofuels

- Pulp and paper

- Water and wastewater

- Mining

- Power

- Unloading terminals

Related Industries

- Power

- Conventional Steam, Combined Cycle, Biomass & MSW

- Chemicals

- Basic (Organic & Inorganic), Biofuels

- Water

- Water Management

- Oil & Gas

- Downstream Processing

Specification

- Complete with API 682

- Pressure

- Pusher: Up to 21 bar (300 psig)

- Bellows: Up to 14 bar (200 psig)

- Temperature: -40 to 204°C (-40 to 400°F)

- Speed: Up to 23 m/s (75 fps)

- Specific Gravity >0.6

- Shaft Size

- Pusher: 25.40 to 203.2 mm (1.000 to 8.000 inch)

- Bellows: 25.40 to 95.25 mm (1.000 to 3.750 inch)

- Materials of Construction

- Metal Parts: 316 Stainless Steel, Alloy C-276

- Mating Ring: Direct Sintered Silicon Carbide

- Primary Ring: Resin Grade Carbon, Direct Sintered Silicon Carbide

- Metal Bellows: Alloy C-276

- Springs: Alloy C-276

- Elastomers: Fluoroelastomer, Perfluoroelastomer

Benefit

- According to API 682 design and test criteria, these pumps are Category 1 ASME B73.1 and Category 2 API 610.

- Type A pusher seals have multiple coil springs that are non-rotating and non-wetted, ensuring exceptional clogging resistance even in the presence of defective equipment alignment conditions.

- Type B seals have edge-welded metal bellows that revolve with the shaft, creating a self-cleaning effect that helps to avoid dirt accumulation.

- Thermal management technology improves seal face heat transmission, lowers seal face temperatures and increases tolerance to dry running conditions.

- All models have hydraulically retained and double balanced seal faces, allowing for continuous operation during inadvertent reverse pressurization.

- The circulating device built within the dual seal cartridge circulates barrier fluid to keep the seal faces cool. For fluids above 75°C (167°F), a circulating device is also available with single seals.

- The available multiport flush distributes flush fluid evenly throughout the seal faces, reducing temperature gradients and improving seal face flatness.

- Gland throttle bushings are offered in fixed, floating and segmented configurations for secondary containment in single seal setups.

ISC2 Series Cartridge Seal – Brochure

Mechanical Seal Quick Ship Flyer

ISC2 682 Series Cartridge Seal – Brochure

Ensure the reliability of your equipment with the ISC2 682 mechanical seal. Contact us now to explore its features and discuss your industrial sealing needs.