Flowserve IDP Catalogue

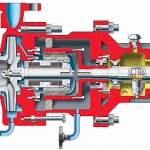

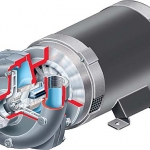

Radially Split Pressure Casings are positively located by interstage rabbet fits, ensuring overall pump concentricity and rotor alignment. Non-shear, compression-type O-rings positively seal channel rings.

Precision-cast Diffusers create symmetrical passageways around the impellers to equalize radial loads, resulting in increased bearing, wear ring and seal life plus tolerance to transient conditions.

Heavy-duty Rotor with short bearing spans minimizes deflection and prolongs bearing and seal life. Tight tolerances and precision fit impellers ensure proper clearance, concentricity and runout.

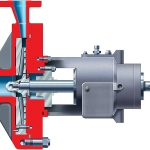

The WCC is a multistage, diffuser-type barrel pump that uses a tandem or opposing impeller rotor and a single-diameter balancing drum to compensate for residual axial thrust.

With a spare, the conventional cartridge-type design enables for rapid changeout, reducing lost production. The WCC Between Bearings Pump is the optimum option when process requirements necessitate a versatile, low-cost solution that is also fully compatible with API 610/ISO 13709 standards. Its wide range of features and metallurgical capabilities allow it to meet almost every oil and gas requirement.

The WCC pump is a general-purpose barrel pump that is CE and ATEX certified and conforms to the most recent standard of ISO 13709/API 610 (BB5). According to the ASME Pressure Vessel Code Section VIII, Div. 1, pressure-containing elements are:

Flowserve engineers will also assist users in addressing and including site-specific needs, while, at the very least, meeting minimum standards for:

• Mechanical seals comply with ISO 21049/API 682

• API 610 or 614 lubricating systems.

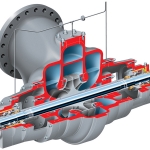

The IDP WXM Between Bearings Pump has a segmental ring, medium pressure diffuser design. A device for axial thrust balance with a multilayer rotor construction. Suitable for boiler feed pump applications in biomass, solar energy, steam generation and industrial boiler projects.

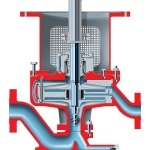

WXH Between Bearing, Radially Split, Multistage, Ring Section Pump

WXH Between Bearing, Radially Split, Multistage, Ring Section Pump

| Brand: | IDP |

|---|---|

| Description: |

The Flowserve WXH is a high-pressure, ring section pump with a horizontal between bearings configuration and radially split casing. Engineered for demanding applications such as boiler feedwater systems, power plants, and industrial utilities, the WXH pump offers robust hydraulic performance, modular design flexibility, and API 610 compliance. Its multistage layout makes it ideal for continuous operation under high-pressure and high-temperature conditions. |

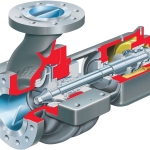

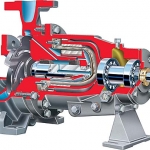

HPX ISO 13709/API610 (OH2) Hydrocarbon Processing Pump

HPX ISO 13709/API610 (OH2) Hydrocarbon Processing Pump

| Brand: | IDP |

|---|---|

| Description: |

Engineered and built for reliable, safe performance, the Flowserve HPX pump also provides optimal emissions containment. This pump represents the industry standard for OH2 single-stage, overhung configurations, fully compliant with ISO 13709 / API 610. Designed for refining, petrochemical, and general industrial services, the HPX delivers superior hydraulic performance, reduced vibration, and long-term operating reliability across a wide range of high-temperature and corrosive applications. |

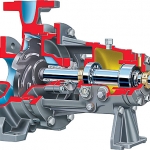

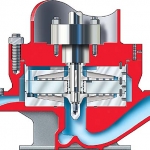

HDX ISO 13709/API 610 (BB2) Between Bearings, Single Case, Radially Split, Single Stage Double Suction Pump

HDX ISO 13709/API 610 (BB2) Between Bearings, Single Case, Radially Split, Single Stage Double Suction Pump

| Brand: | IDP |

|---|---|

| Description: |

The Flowserve HDX pump bridges the flow and pressure disparity between overhung and multistage process pump lines. Fully compliant with ISO 13709 / API 610 (BB2), this radially split, single-case, between bearings pump features a horizontal axially split casing with double suction impeller. It is designed for reliable operation in mid-range flow and pressure applications, including oil and gas processing, chemical plants, water injection and general industrial services. The HDX delivers smooth performance, excellent hydraulic efficiency and low NPSHr characteristics for extended pump life and reduced operational costs. |

HWX API 610 (OH3), Overhung, Vertical In-Line Pump

HWX API 610 (OH3), Overhung, Vertical In-Line Pump

| Brand: | Byron Jackson, IDP, Worthington, United Centrifugal, Wilson-Snyder, Pacific |

|---|---|

| Description: |

The Flowserve HWX is an API 610 OH3 vertical in-line process pump designed to deliver high reliability and space-saving installation in critical refinery, petrochemical and industrial process systems. Built with a heavy-duty bearing frame and centerline casing support, the HWX is engineered for thermal stability, low vibration, and easy maintenance. |

WMA2 Two Stage, Rigidly Coupled, Vertical In-line, Low-Flow, High-Head Process Pump

WMA2 Two Stage, Rigidly Coupled, Vertical In-line, Low-Flow, High-Head Process Pump

| Brand: | IDP |

|---|---|

| Description: |

The Flowserve WMA2 is a two-stage, rigidly coupled vertical in-line pump engineered to meet API 610 OH4 standards. Like the HWMA2 model, it is specifically designed for low-flow, high-head applications where space is limited and reliability is critical. With its compact vertical footprint, robust shaft design and precision-balanced hydraulics, the WMA2 offers efficient performance and ease of maintenance in demanding refinery, chemical, and industrial process environments. |

WMA ISO 13709/API 610 (OH4) Rigidly Coupled, Vertical In-line, Low-Flow, High-Head Process Pump

WMA ISO 13709/API 610 (OH4) Rigidly Coupled, Vertical In-line, Low-Flow, High-Head Process Pump

| Brand: | IDP |

|---|---|

| Description: |

The Flowserve WMA is a rigidly coupled vertical in-line pump built to ISO 13709 / API 610 (OH4) standards. It shares the same proven hydraulics as the WMA2 and HWMA2 models, offering reliable performance in low-flow, high-head conditions. Compact and efficient, the WMA pump is ideal for tight-space installations in refineries, chemical plants, and general industrial services. Its OH4 construction ensures shaft stiffness, alignment integrity, and minimal vibration for long-term operation with reduced maintenance. |

HWMA ISO 13709/API 610 (OH3) Vertical In-line, Low-Flow, High-Head Overhung API Process Pump

HWMA ISO 13709/API 610 (OH3) Vertical In-line, Low-Flow, High-Head Overhung API Process Pump

| Brand: | IDP |

|---|---|

| Description: |

The Flowserve HWMA is a single-stage, vertical in-line overhung pump featuring a separate bearing bracket, designed to fully comply with ISO 13709 / API 610 (OH3) standards. With its small footprint, this pump is ideal for installations where space is limited but performance cannot be compromised. The HWMA excels in low-flow, high-head services such as high-pressure injection, chemical transfer, and utility applications in refineries and process plants. Its vertical overhung design ensures excellent shaft support, smooth operation, and long-term mechanical reliability. |

CPX ISO Overhung, Single Stage Process Pump

CPX ISO Overhung, Single Stage Process Pump

| Brand: | IDP |

|---|---|

| Description: |

The Flowserve CPX is a horizontal, overhung, single-stage process pump designed to conform to ISO 2858 dimensional and ISO 5199 design criteria. Incorporating advanced features for improved reliability and ease of maintenance, the CPX chemical process pump is ideal for handling corrosive and aggressive fluids in chemical processing, pharmaceuticals, pulp and paper and general industrial applications. With its precision-engineered hydraulics, rigid shaft design and heavy-duty bearing system, the CPX delivers long-lasting performance in continuous-duty operations. |

CPXV ISO and API Chemical Sump Pump

CPXV ISO and API Chemical Sump Pump

| Brand: | IDP |

|---|---|

| Description: |

Compliant with ISO 5199 standards, the Flowserve CPXV is a vertical sump pump featuring advanced hydraulics engineered for efficient and reliable pumping of corrosive, abrasive, or hazardous fluids. Its rugged vertical design is ideal for chemical processing, wastewater treatment, and industrial sumps where space savings and easy access are critical. The CPXV offers various column lengths and impeller options, ensuring flexibility in handling diverse process conditions while delivering low vibration and extended service life. |

HPXM ISO 13709/API 610 (OH2) Low Flow, High Head Horizontal Process Pump

HPXM ISO 13709/API 610 (OH2) Low Flow, High Head Horizontal Process Pump

| Brand: | IDP |

|---|---|

| Description: |

Fully compliant with ISO 13709 / API 610 (OH2), the Flowserve HPXM is a horizontal overhung process pump specifically engineered for low-flow, high-head applications. Designed to operate reliably under extreme conditions, the HPXM is ideal for critical services such as chemical injection, boiler feed, and high-pressure process systems in the oil, gas, and chemical industries. Its heavy-duty construction, optimized hydraulics, and compact OH2 footprint ensure stable performance, excellent efficiency, and long service life. |

CPXR Recessed Impeller ISO Chemical Process Pump

CPXR Recessed Impeller ISO Chemical Process Pump

| Brand: | IDP |

|---|---|

| Description: |

The Durco CPXR is an ISO-compliant chemical process pump equipped with a recessed impeller, purpose-built for low-shear pumping of friable solids and fibrous or stringy materials. Designed for handling slurries, sludge, and other challenging fluids, the CPXR provides clog-free, gentle pumping performance in chemical, pulp and paper, food processing, and wastewater applications. Its recessed impeller design minimizes product degradation while maintaining efficient hydraulic operation and robust reliability. |

CPXM ISO Overhung, Close Coupled, Process Pump

CPXM ISO Overhung, Close Coupled, Process Pump

| Brand: | IDP |

|---|---|

| Description: |

The Durco CPXM is a close coupled, overhung chemical process pump designed to ISO 2858 and ISO 5199 standards. Offering state-of-the-art hydraulics in a compact, space-saving arrangement, the CPXM pump is ideal for applications where installation footprint is limited but performance and reliability cannot be compromised. Engineered for corrosive and hazardous fluid handling, the CPXM delivers efficient flow, simplified alignment, and reduced maintenance in chemical, pharmaceutical, and general industrial services. |

MEN Overhung, End Suction Industrial Process Pump

MEN Overhung, End Suction Industrial Process Pump

| Brand: | IDP |

|---|---|

| Description: |

The Flowserve MEN is a rugged, overhung, end suction industrial pump designed for reliable operation in general-purpose water and utility applications. Known for its versatility and dependable hydraulic performance, the MEN pump is ideal for cooling water circulation, water supply, HVAC, irrigation, and auxiliary process services across industrial plants and facilities. Built with simplicity and durability in mind, it offers a cost-effective solution with minimal maintenance and long service life. |

Hydrex Double Helical, Rotary Gear Pump

Hydrex Double Helical, Rotary Gear Pump

| Brand: | IDP, Worthington |

|---|---|

| Description: |

The Flowserve Hydrex is a double helical rotary gear pump designed for smooth low-pulsation flow in handling viscous fluids such as lubricating oils, fuels, polymers, and light chemicals. With rugged internal timing gears and precise engineering, the Hydrex delivers excellent volumetric efficiency and long service life even in demanding industrial applications. |

ERPN-M Overhung, Magnetic Drive Process Pump

ERPN-M Overhung, Magnetic Drive Process Pump

| Brand: | Worthington, IDP |

|---|---|

| Description: |

The Flowserve ERPN-M is an overhung magnetic drive centrifugal pump designed for leak-free fluid handling in chemical processing, industrial utilities, and hazardous liquid transfer. With a sealless magnetic drive configuration, the ERPN-M offers superior containment, reduced maintenance, and enhanced safety for applications where environmental protection is critical. |

CPXS Magnetic Drive, Overhung, Chemical Process Pump

CPXS Magnetic Drive, Overhung, Chemical Process Pump

| Brand: | IDP |

|---|---|

| Description: |

The Durco CPXS is a magnetic drive, overhung chemical process pump engineered for leak-free operation in the handling of hazardous, toxic, flammable, explosive, or high-value liquids. Conforming to ISO 2858 and ISO 15783 standards, the CPXS eliminates the need for mechanical seals, offering maximum containment, safety, and minimal maintenance. Its advanced hydraulics and containment shell make it ideal for chemical, pharmaceutical, semiconductor, and specialty fluid industries requiring absolute reliability in corrosive or dangerous service environments. |

CPXP Self-Priming ISO Chemical Process Pump

CPXP Self-Priming ISO Chemical Process Pump

| Brand: | IDP |

|---|---|

| Description: |

The Flowserve CPXP is a self-priming, overhung chemical process pump designed in accordance with ISO 2858 and ISO 5199 standards. Operating on the reflux priming principle, the CPXP pump offers state-of-the-art hydraulics and a compact, space-saving arrangement, making it ideal for applications where suction lift conditions are challenging. Its design facilitates efficient and reliable pumping of corrosive and hazardous fluids in chemical processing, pharmaceuticals, and other industrial applications. |

WXB-B Low-Flow, High-Head, Process Barrel Pump

WXB-B Low-Flow, High-Head, Process Barrel Pump

| Brand: | IDP |

|---|---|

| Description: |

The Flowserve WXB-B is a low-flow, high-head multistage barrel pump engineered in accordance with API 610 standards. As an extension of the proven WXB series, the WXB-B incorporates Barske-style impellers for optimized performance in high-pressure, low-capacity services. Its rugged construction and compact barrel design make it ideal for boiler feed, hydrocarbon processing, and other critical services where precision flow control and reliability are essential. The WXB-B delivers smooth, stable operation even in demanding process environments with low NPSH conditions. |

WM2 API 610 (OH5), Overhung, Close Coupled, Vertical In-Line, Low Flow, Two Stage Pump

WM2 API 610 (OH5), Overhung, Close Coupled, Vertical In-Line, Low Flow, Two Stage Pump

| Brand: | IDP |

|---|---|

| Description: |

The Flowserve WM2 is a two-stage, close-coupled vertical in-line pump designed in accordance with ISO 13709 / API 610 (OH5) standards. Engineered for low-flow, high-head services, the WM2 pump features a compact design that eliminates the need for a separate bearing housing. Its modular construction allows for over 100 Best Efficiency Point (BEP) fits within a single pump size, ensuring optimal performance across various applications. The WM2 is ideal for industries such as oil and gas, petrochemical processing, and high-temperature services, where space-saving and reliable operation are critical. |

WM API 610 (OH5), Overhung, Close Coupled, Vertical In-Line, Low Flow Pump

WM API 610 (OH5), Overhung, Close Coupled, Vertical In-Line, Low Flow Pump

| Brand: | IDP |

|---|---|

| Description: |

The Flowserve WM is the space-saving, close-coupled configuration of the HWM pump, designed to meet API 610 (OH5) standards. Specifically engineered for low-flow process applications, the WM pump offers a vertical in-line arrangement that minimizes installation footprint without sacrificing performance. With its rigid shaft alignment and simplified maintenance features, the WM is ideal for chemical, petrochemical, and general industrial services where compact reliability is key. |

WDF Nuclear Vertical, Single Stage Pump

WDF Nuclear Vertical, Single Stage Pump

| Brand: | IDP |

|---|---|

| Description: |

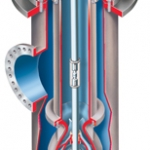

The Flowserve WDF is a vertical, single-stage pump specifically designed for safety-related shutdown services in nuclear power plants. Engineered to comply with ASME Section III, Class 2 and 3 standards, the WDF pump is optimized for critical applications such as residual heat removal (RHR), containment spray, and low-pressure safety injection systems. Introduced in the 1970s, the WDF pump has established an excellent record of reliability in RHR applications in nuclear power stations worldwide. Its design features a vertical, single-stage, diffuser-style configuration with a forged diffuser casing, ensuring structural integrity and efficient hydraulic performance. The pump incorporates a removable spacer coupling, facilitating seal and bearing maintenance without disturbing the motor or casing cover. Additionally, the separate bearing support above the seal chamber provides shaft support and reduces vibration input to the mechanical seal. |

W API 610 (OH4), Radially Split, Vertical In-Line, Rigid Coupled, Process Pump

W API 610 (OH4), Radially Split, Vertical In-Line, Rigid Coupled, Process Pump

| Brand: | Wilson-Snyder, Worthington, Pacific, Byron Jackson, IDP, United Centrifugal |

|---|---|

| Description: |

The Flowserve W pump is a vertical in-line, radially split, rigid coupled process pump built to meet API 610 (OH4) standards. Engineered for compact, space-saving installations in refineries, chemical plants, and general industrial services, the W pump offers high reliability, excellent shaft alignment, and simplified maintenance for continuous-duty operation. |

SMX Non-Metallic Standard Motor Overhung Industrial Process Pump

SMX Non-Metallic Standard Motor Overhung Industrial Process Pump

| Brand: | IDP |

|---|---|

| Description: | The SMX Non-Metallic Standard Motor Overhung Industrial Process Pump is engineered for applications requiring corrosion resistance and reliable performance. Featuring a polyphenylene sulfide (PPS) casing, adapter, and impeller, the SMX pump offers a cost-effective alternative to metallic pumps in various industrial processes. Its design includes a back pull-out configuration for easy maintenance and a standard NEMA 56J frame C-faced motor for flexibility and interchangeability. The pump’s self-aligning mechanical seal with stainless steel components ensures minimal leakage and extended service life. With operating parameters accommodating flows up to 25 m³/h (100 gpm), heads to 20 m (60 ft), pressures to 12 bar (175 psi), and temperatures up to 80°C (180°F), the SMX pump is suitable for water treatment, HVAC, chemical processing, and general industrial applications. |

SMP Standard Motor Overhung Industrial Process Pump

SMP Standard Motor Overhung Industrial Process Pump

| Brand: | IDP |

|---|---|

| Description: | The Flowserve SMP is a horizontal, frame-mounted, single-stage overhung process pump designed for general industrial services. Equipped with high-efficiency semi-open or closed impellers, the SMP pump offers reliable performance across various applications, including water treatment, HVAC, and auxiliary chemical processes. Its back pullout design facilitates easy maintenance, while the use of industry-standard NEMA motors ensures flexibility and interchangeability. The SMP pump is suitable for handling a wide range of fluids, making it a versatile choice for numerous industrial processes. |

MSX Overhung, Solids Handling, Submersible Pump

MSX Overhung, Solids Handling, Submersible Pump

| Brand: | IDP |

|---|---|

| Description: |

The Flowserve MSX is a rugged, overhung, solids-handling submersible pump engineered for demanding wastewater and industrial applications. Designed to handle sewage, sludge, and other solid-laden fluids, the MSX pump features a non-clog impeller and a robust construction that ensures reliable performance in challenging environments . Equipped with a high-efficiency motor and a closed-loop cooling system, the MSX pump is suitable for both wet and dry pit installations. Its design includes features such as moisture detection sensors, thermal protection, and spike-resistant windings, which contribute to extended service life and reduced maintenance requirements . The MSX pump is available in various sizes and configurations to meet specific application needs. |

HWMA2 ISO 13709/API 610 (OH3) Vertical In-line, Low-Flow, High-Head Overhung API Process Pump

HWMA2 ISO 13709/API 610 (OH3) Vertical In-line, Low-Flow, High-Head Overhung API Process Pump

| Brand: | IDP |

|---|---|

| Description: |

The Flowserve HWMA2 is a two-stage, vertical in-line overhung pump designed in accordance with ISO 13709/API 610 (OH3) standards. It features a separate bearing housing and a compact footprint, making it ideal for low-flow, high-head applications in industries such as oil and gas, petrochemical, and power generation. The HWMA2’s modular design allows for over 80 best efficiency point (BEP) fits within a single pump size, optimizing efficiency and reducing energy consumption. The HWMA2 pump utilizes back-to-back, radial blade impellers to achieve high-head performance while equalizing axial thrust. Its robust construction includes features such as a replaceable volute insert for precise hydraulic customization, a heavy-duty motor support head with a registered fit motor mount, and an optional inducer to reduce NPSH requirements. These design elements contribute to the pump’s reliable operation and ease of maintenance in demanding process environments. |

ESP3 Chemical Vertical Sump Pump

ESP3 Chemical Vertical Sump Pump

| Brand: | IDP |

|---|---|

| Description: | The Flowserve ESP3 is a ruggedly built, vertical immersion sump pump engineered for demanding chemical and hydrocarbon processing applications. It features a reverse vane impeller and shares hydraulic components with the Durco Mark 3™ pump, allowing for parts interchangeability and reduced inventory costs. The ESP3 is designed to provide improved performance, increased part standardization, and a low total cost of ownership. |

EG Nuclear Radially Split, Double Suction Pump

EG Nuclear Radially Split, Double Suction Pump

| Brand: | IDP |

|---|---|

| Description: |

The Flowserve EG is a single-stage, radially split, double-suction pump engineered for heavy-duty component cooling water service in nuclear power plants. Designed in compliance with ASME Section III, Class 3 and RCC-M standards, the EG pump provides reliable performance in safety-related applications. Its robust construction features a radially split casing that facilitates maintenance without disturbing the piping, and a double-suction impeller that offers hydraulic balance, reducing axial thrust. The EG pump is specifically designed to handle the rigorous demands of nuclear component cooling systems, ensuring operational reliability and safety . |

CSB Between Bearings, Double Case, Diffuser Casing, Multistage, Utility Barrel Pump

CSB Between Bearings, Double Case, Diffuser Casing, Multistage, Utility Barrel Pump

Brand |

Description |

| IDP | The CSB Between Bearings Double Case Diffuser Casing Multistage Utility Barrel Pump is designed to deliver superior performance and efficiency for demanding industrial applications. Engineered for durability and ease of maintenance, this pump is ideal for use in critical services, such as boiler feed and thermal power plant operations. With its advanced diffuser-style design, the CSB Pump ensures reliability and cost-effectiveness, meeting the rigorous demands of modern industries. |

CHTA BETWEEN BEARINGS DIFFUSER CASING, UTILITY BARREL PUMP

| BRAND | DESCRIPTION |

| FLOWSERVE |

The Flowserve CHTA is a horizontally mounted, multistage, between-bearings barrel pump engineered for high-pressure utility applications such as boiler feedwater and startup services in thermal and combined cycle power plants. Its double-case, radially split inner casing design ensures structural integrity under extreme operating conditions, while the precision-cast diffusers and tandem impellers deliver efficient hydraulic performance. The CHTA’s robust construction and advanced features make it a reliable choice for demanding industrial processes. |

| Brand | IDP |

|---|---|

| Description | The Flowserve CSX Between Bearings Pump is a Horizontal Multistage Pump designed for high-efficiency, high-pressure membrane feed applications, especially in reverse osmosis desalination systems. With advanced corrosion-resistant materials and precision design, it delivers reliable, energy-efficient performance and reduced lifecycle costs. |

Brand |

Description |

| IDP | The CA pump was specifically built for nuclear safety injection service. This radially split, between-bearing, multistage Flowserve CA Nuclear Pump is extremely reliable and efficient, making it an excellent choice for sensitive nuclear pump applications that require high-performance pumps. |

APKD Vertical, Double Case, Double Suction Pump

APKD Vertical, Double Case, Double Suction Pump

| Brand: | IDP |

|---|---|

| Description: | The Flowserve APKD is a vertical, double-case, double-suction pump engineered to deliver high efficiency and reliable performance in applications with limited Net Positive Suction Head available (NPSHa). Its twin-volute design and double-suction first-stage impeller minimize radial and axial loads, ensuring stable operation across a wide flow range. Available with four impeller hydraulic options—steep, standard, flat, and super-flat—the APKD pump can be precisely tailored to meet specific system requirements, reducing energy consumption and total cost of ownership. |

CN Radially Split, Diffuser Casing, Single-Stage Nuclear Pump

CN Radially Split, Diffuser Casing, Single-Stage Nuclear Pump

| Brand: | IDP |

|---|---|

| Description: | The Flowserve CN is a single-stage, high-speed pump featuring a rugged, diffuser-style barrel design. Designed to meet ASME Section IV Division 1 requirements, it incorporates a centerline-mounted, radially split casing and a double-suction impeller. This configuration ensures nearly balanced axial hydraulic thrust across the full operating range, making it ideal for demanding nuclear applications. |