B15 Hygienic Pump

B15 Hygienic Pump

B15 Hygienic Pump

The B15 Hygienic Pump is a compact yet powerful air operated double diaphragm pump (AODD) engineered specifically for sanitary fluid transfer. Whether handling high-viscosity liquids, cleaning solutions or delicate food-grade fluids, this pump delivers safe and efficient operation across food, beverage, dairy and pharmaceutical environments.

Built using FDA-compliant materials, and offering ATEX certification for explosive zones, the B15 is ideal for processors who require performance, safety and compliance in one hygienic package.

Key Features

- Available in DIN, RJT and Ferrule connection types

- Self-priming, suitable for container and drum emptying

- Equipped with food-grade EPDM and PTFE diaphragms

- Delivers pressures up to 8.6 bar (125 PSI)

- Handles high-viscosity and high-S.G. fluids with ease

- Constructed from 316L stainless steel for superior hygiene and corrosion resistance

Lightweight and ATEX-certified for safe operation in hazardous zones

Technical Specifications

| Specification | Details |

| Maximum Delivery | 75 ltrs/min (20 gal/min) |

| Max. Working Pressure | 8.6 bar (125 PSI) |

| Max. Solid Particle Size | 2 mm (0.08″) |

| Air Inlet | 1/4″ NPT |

| Temperature Limits | Determined by Elastomer Type |

| Suction Lift (Dry) | 4.6 metres (15.1 feet) |

| Suction Lift (Wet) | 6.1 metres (20 feet) |

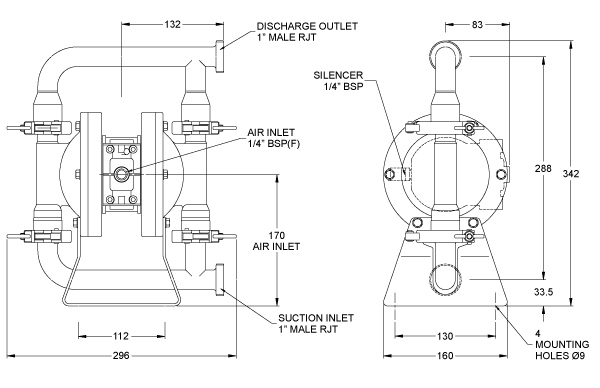

| Fluid Inlet / Outlet | 1″ RJT (standard) |

| Installation | Wall or surface mounted |

| Accessories Included | Exhaust Air Silencer |

| Shipping Weight | 10.5 kg (Stainless Steel/Aluminum), 15.8 kg (SS only) |

| Shipping Dimensions | 320 x 210 x 390 mm (12.6″ x 8.3″ x 15.4″) |

Material & Temperature Compatibility

Choosing the right diaphragm or valve seat material ensures the best performance and durability. The B15 offers several material configurations to match different chemical and temperature demands:

| Material | Max Temp (°C/°F) | Min Temp (°C/°F) | Optimal Range (°C/°F) | Properties |

| Buna-N | 80°C / 176°F | -28°C / -18°F | 10–60°C / 50–140°F | Oil resistant; not for polar solvents |

| EPDM | 100°C / 212°F | -24°C / -11°F | 10–100°C / 50–212°F | Hot water and CIP fluids |

| Neoprene | 100°C / 212°F | -20°C / -4°F | 10–54°C / 50–130°F | General-purpose use |

| Santoprene® | 100°C / 212°F | -23°C / -10°F | 10–100°C / 50–212°F | Abrasion resistance, long flex life |

| PTFE (Teflon) | 180°C / 356°F | 0°C / 32°F | 10–100°C / 50–212°F | Chemically inert |

| Viton® | 180°C / 356°F | -18°C / 0°F | 24–100°C / 75–212°F | Excellent chemical resistance |

| Polypropylene | 70°C / 158°F | -40°C / -40°F | 10–60°C / 50–140°F | Corrosion-resistant body material |

B15 Hygienic Pump Applications

- Food processing: Flavourings, syrups, sauces, fillings

- Dairy: Milk derivatives, whey, yogurt cultures

- Beverage: Juices, concentrates, CIP fluids

- Pharmaceuticals: Cleanroom-grade fluid handling

- Chemical & Cosmetics: Acids, alkalis, lotions, gels

Why Choose the B15 for Sanitary Operations?

With its self-priming design, FDA-grade materials, and ability to withstand abrasive or corrosive fluids, the B15 Hygienic Pump is the ideal choice for companies seeking both hygiene and durability in a single solution. Its compact size and ATEX certification make it equally useful in mobile or fixed sanitary systems.

This pump excels in sanitary diaphragm pumping, food grade fluid transfer, and hygienic chemical handling, making it an all-in-one solution for small to mid-scale operations.

Frequently Asked Questions (FAQ)

Q1: Is the B15 Hygienic Pump certified for explosive zones?

Yes. It carries ATEX certification, making it safe for use in hazardous and flammable environments.

Q2: Can this pump handle viscous or thick products?

Absolutely. The pump is designed for high-viscosity and high-specific gravity (S.G.) fluids commonly found in food and chemical applications.

Q3: What materials are available for wetted parts?

We offer options such as EPDM, PTFE, Viton®, Santoprene®, and Buna-N to match your process fluid requirements.

Q4: Can it be integrated into a clean-in-place (CIP) system?

Yes. With the right diaphragm materials like EPDM or PTFE, this pump supports CIP operations.

Q5: Is this pump suitable for pharmaceutical use?

Yes, the B15 meets the hygienic standards required for many pharmaceutical and biotech applications.

Ensure precise performance for small-scale sanitary applications with the Alfa Laval B15 Hygienic Pump. Contact us today for more details.