SIHI High Pressure Pumps

Pumps of the SIHImulti range meet the specific requirements of many applications, such as waterworks and water supply, boiler feed, pressure boosting..

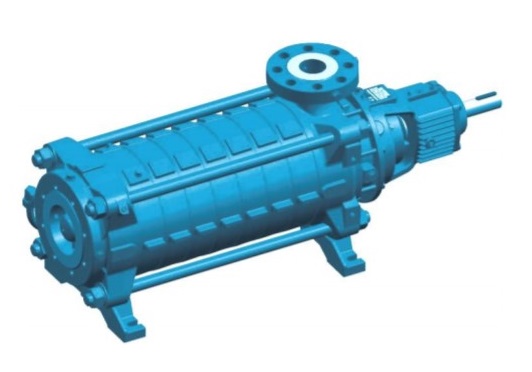

SIHImulti MSL, MSM

SIHImulti MSL, MSM

SIHImulti pumps of the series MSL/MSM are horizontal multistage centrifugal pumps of ring-section design, which meet the technical requirements of ISO 5199 / EN 25199. The advanced modular design reduces the number of parts whilst maximising interchangeability. Optimal selection of impeller diameter and diffuser size for each ensures that the pump closely match the required duty conditions.

Applications:

Pumps of the SIHImulti range meet the specific requirements of many applications, such as waterworks andwater supply, boiler feed, pressure boosting, irrigation, high pressure cleaning, heating, condensate systems, reverse osmosis, chemical and process applications and many more.

Technical Data:

Flow rate: up to 450 m³/h

Head: up to 630 m

Speed: max. 3,600 rpm

Temperature: max. 180 °C

Casing pressure: up to 63 bar

Shaft seals: gland packing, mechanical seal

Materials: grey cast iron, nodular iron, stainless steel

The SIHImulti MSC range of horizontal, ring-section multi-stage pumpshave been designed for long-term reliability when pumping high pressure liquids. The design features within this range of high pressure pumps, provide our customers with unique solutions to long-term concerns about power consumption, efficiency, and reliability.

A special feature is the wide range of speed, which is excellent suitable for frequency inverter running.

Meeting the technical requirements of ISO 5199 / EN25199, they have a modular concept in order to reduce the number of parts, and consequently our customers’ inventory.

Premium levels of efficiency are available by selecting an appropriate set of impellers and diffusers that give an ideal fit to the process requirement. Unique to the multi-stage arena portfolio is the, SIHI, patented self-adjusting drum style of axial thrust balancing. The MSC employ a device that reduces the bypass flow to an absolute minimum, while not being susceptible to long(er) term wear-sensitive clearances.

Applications:

Pumps of the SIHImulti range meet the specific requirements of our customers in selected applications, such as Renewable energy, Fossil power stations, Biomass, Geothermal and Paper and Pulp.

Technical Data:

Flow rate: up to 250 m³/h

Head: up to 1000 m

Speed: max. 3,600 rpm

Temperature: max. 180 °C

Casing pressure: up to 100 bar

Shaft seals: gland packing, mechanical seal

Materials: grey cast iron, stainless steel

SIHImulti MSH

SIHImulti MSH

SIHImulti pumps of the series MSH are horizontal multistage centrifugal pumps of ring-section design, which meet the technical requirements of ISO 5199 / EN 25199. The type MSH is developed for the high pressure range up to PN 160. The advanced modular design reduces the number of parts whilst maximising interchangeability. Optimal selection of impeller diameter and diffuser size for each ensures that the pump closely match the required duty conditions.

Applications:

Pumps of the SIHImulti range meet the specific requirements of many applications, such as waterworks and water supply, boiler feed, pressure boosting, irrigation, high pressure cleaning, heating, condensate systems, reverse osmosis, chemical and process applications and many more.

Technical Data:

Flow rate: up to 250 m³/h

Head: up to 1,600 m

Speed: max. 3,600 rpm

Temperature: max. 180 °C

Casing pressure: up to 160 bar

Shaft seals: gland packing, mechanical seal

Materials: stainless steel

Series UEA

Series UEA

Horizontal, self-priming centrifugal pumps of the segmental type with closed impellers and a suction stage. The suction stage is installed at discharge side. It is arranged in parallel to the last liquid handling stage and operates acc. to the sucking-through principle. The design UEA has an axial inlet with NPSH inducer stage. The axial thrust is compensated by single-impeller relief. The remaining axial thrust are compensated by antifriction bearings of sufficient size. A hydraulically favourable re-routing is done by means of guiding devices in the stage casings.

Applications:

Centrifugal pumps of the series UEA with NPSH inducer stage are applied for trouble-free pumping under unfavourable conditions at suction side. The capability of the pumps in this series to handle liquids at the boiling point, allows a wide-ranging application when handling condensates, liquefied gases, refrigerants, LPG, and boiler feed water.

Technical Data:

Flow rate: up to 220 m³/h

Head: up to 280 m

Speed: max. 3,600 rpm

Temperature: max. 140 °C

Casing pressure: up to 40/25 bar

Shaft seals: gland packing, mechanical seal

Materials: grey cast iron, nodular iron, stainless steel

TKH

TKH

Horizontal, self-priming and segmental type centrifugal pumps with shrouded impellers and a priming stage arranged on the suction side. The priming stage runs in parallel with the first liquid stage and operates acc. to the mixed media separation principle during the priming phase and in case of big gas portions. As result of the separation of the gas before entering the first impeller this is largely admitted with liquid. Finely divided gas portions can be handled without problems. If during the priming cycle, the counter pressure on the discharge side is below 0.5 bar, the pumped-away gas is discharged into the delivery pipeline. If the counter pressure is higher than 0.5 bar, then a separate gas discharging device is required.

Applications:

The self-priming centrifugal pump of series TKH is used, when clear or turbid liquids, free from solid particles, are to be handled reliably and trouble-free. Because of their self-priming capability and owing to the multitude of material combinations, the pumps cover a wide range of applications in such fields as the supply of drinking and utility water (for greater communities and large industrial plants), the handling of fuel (in decanting stations and large tank plants), the construction of fire-extinguishing equipment, the construction of cooling plants, shipbuilding (ballast and stripping pumps), the chemical industry and the petrochemical industry.

Technical Data:

Flow rate: up to 350 m³/h

Head: up to 185 m

Speed: max. 3,600 rpm

Temperature: max. 120 °C

Casing pressure: up to 16 bar

Shaft seals: gland packing, mechanical seal

Materials: grey cast iron, bronze, stainless steel