Flowserve RedRaven

Flowserve RedRaven

Flowserve RedRaven

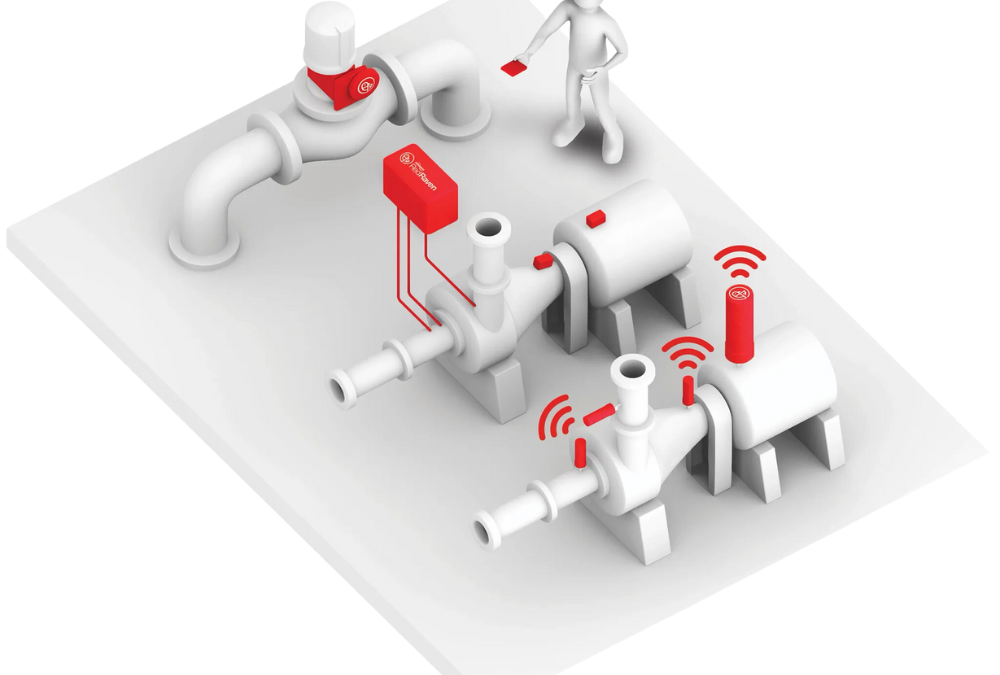

RedRaven, Flowserve’s end-to-end industrial IoT solution, delivers the tools and insights needed to monitor and optimise flow control equipment performance, as well as proactively identify and fix issues before they create downtime or interruptions.

RedRaven provides a comprehensive solution that improves plant efficiency, productivity and dependability through clear insights.

Flowserve developed the RedRaven platform to help you monitor, assess and anticipate the performance of your plant’s pumps, seals and valves, allowing you to fix problems quickly and save downtime.

RedRaven provides hazardous area-certified equipment sensors, secure communication, performance analytics and trend reporting. It also provides customized solutions for your plant. Condition monitoring services collect asset performance data for analysis, whereas predictive monitoring uses data analysis tools and algorithms to diagnose equipment problems.

Advanced analytics and trend data can detect even little variations in equipment performance, which could indicate a problem. RedRaven’s engineered analytics, diagnostics and predictive capabilities evaluate flow control equipment performance. You’ll get data and insights to help you make better decisions and improve your plant’s efficiency, production, and bottom line.

The Flowserve Data Transfer Box (DTB) is a critical component of RedRaven’s anticipated analysis of valves, seals and pumps. The box is utilized to transmit data from tethered sensors to the Flowserve cloud via LAN or cellular connections. The Insight portal analyses this data to assist in the monitoring of equipment in near real time, enabling us to identify issues prior to their occurrence, thereby preventing outage.

The data collection is intended to collect a variety of information, including vibration, temperature, pressure and flow, as well as other monitor data, in order to provide a comprehensive understanding of the system.

The Detect sensor from Flowserve is a cost-effective and straightforward-to-install device that enables the monitoring of vibrations in rotating machinery. It is available with “Ex ia” ATEX, IECEx, and QPS certificates for use in Zone 0 and Division 1 applications, as well as Class 1 Division 1. Detect sensor measures total root mean square (RMS) vibration up to 1 kHz and acceleration spectrum up to 5.6 kHz, in accordance with ISO 20816 and API 610. The compressed vibration spectrum is employed by the Red Raven gateway to identify aberrant operating conditions, thereby directing performance in accordance with established thresholds.

Apart from the compressed Fast Fourier Transform (FFT), Detect Sensor records the total acceleration and velocity every thirty seconds. After comparing the data with auto-calibrated thresholds for vibration intensity levels, the sensor activates an integrated colour-coded LED (green, yellow, or red) to notify technicians of the current operating conditions.

The 4–20 mA HART® interface is used to transfer data, which is then used to provide online condition monitoring in the Red Ravens portal or in current process control systems. It is also possible to wirelessly transmit this data using the Red Raven Data Transfer Box.

The Node ER sensor is a component of Flowserve’s low-power, wide-area network (LoRaWAN) system, which is designed to provide almost real-time asset health monitoring of industrial equipment through the company’s comprehensive end-to-end internet of things (IoT) solution. Node ER is a wireless sensor that is powered by batteries and is capable of transmitting a significant quantity of equipment performance data over long distances in a secure manner. It is capable of collecting, encrypting, and transmitting three-dimensional vibrations, temperature, and pressure data at a distance of up to 1.6 km (1 mile). With only a limited number of gateway devices and Node ER, it is possible to rapidly cover extensive areas or structures.

Node ER sensors can be directly installed on pumps and other assets throughout a facility, including hazard-rated areas (Class I Div 1/ATEX Zone 0).

It is an ideal solution for large refineries or other operations that necessitate a dependable and reasonably priced IoT condition monitoring solution due to its wireless, long-range capabilities, as well as its optimal communication protocol and strong modulation scheme.

The backbone of Flowserve’s entire IoT solution is Node ER, which ensures that sophisticated installations such as those involving wired sensors do not cause excessive plant disturbance. Flowserve’s LoRaWAN system is the optimal option for the implementation of over hundreds of assets due to this reason.

Node Er Wireless Sensor Data Sheet

Optimise your operations with Flowserve RedRaven, the cutting-edge solution for asset management and predictive maintenance. Reach out to us today to discover how RedRaven can enhance your efficiency and reduce downtime.