Centrifugal Plastic Pumps Catalogue

Description

- Viscosity: 200 cSt

- Capacity: up to 140 mc/h

- Delivery Head: up to 44 m

- Speed: 1450 / 3500 rpm

- Temperature: From -85°C to 90°C (higher temp. on request)

- Casing pressure: PN 6

- Flange connections: UNIVERSAL DESIGN ACC. TO DIN EN 1 092-2 / PN 10, ANSI B16.5 150 lbs.

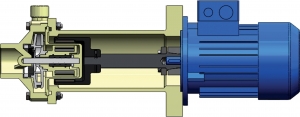

Pump construction

Close-coupled drivers are conventional drivers mounted directly to pumps frame. No base, coupling or guards are required for this mounting style. Universal Flanges Connections that meet DIN PN16 and ANSI 150#.

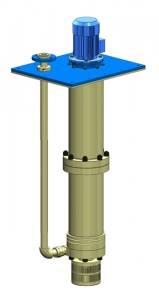

Pump construction and Operative limits

Close-coupled drivers are conventional drivers mounted directly to pumps frame. No base, coupling or guards are required for this mounting style.

Operating limits

- Max viscosity: 200 cSt

- Flow up: to 140 mc/h

- Head up:to 44 m

- Temperature range: from -22 °F (-30 °C) to +194 °F (+90 °C)

- Electric motors: from 1,5 up to 18,5 kW

- Lenght up: to 7 m

Pump construction and Operating Limits

- Close-coupled configuration allows conventional drivers to be mounted directly to pump frame. No base, coupling or guards are required for this mounting.

- Connections: Threaded BSP (GAS) & NPT.

- Max viscosity: 200cSt

- Max system pressure: 5 bar

- Flow up: to 30 mc/h

- Head up: to 24 m

- Temperature range: from -76 °F (-60 °C) to +194 °F (+90 °C)

- Electric motors: from 1.5 up to 7.5 kW