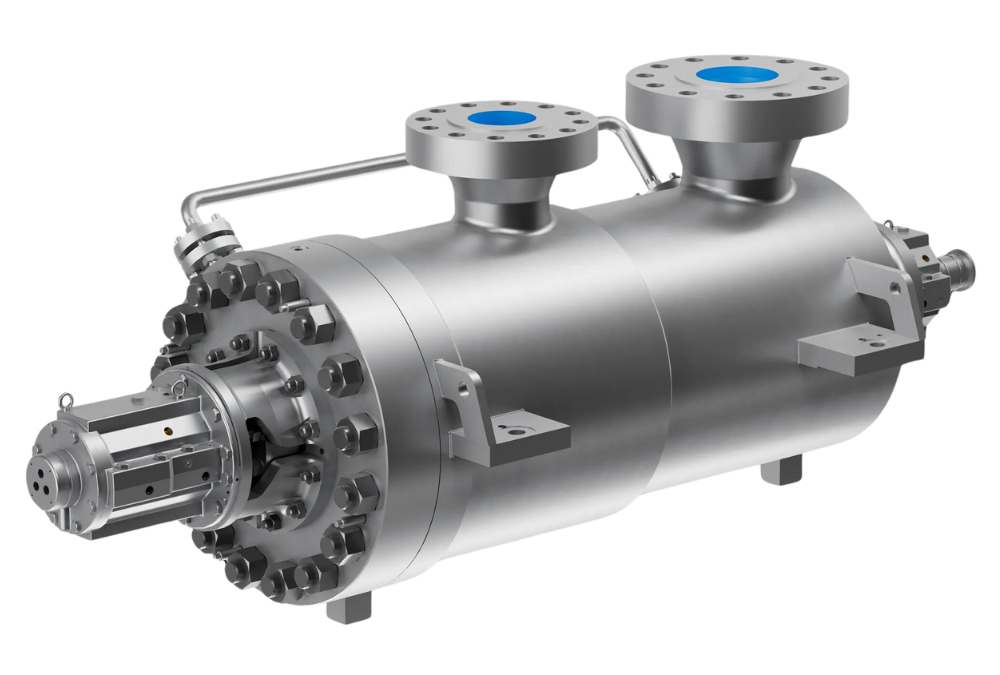

Byron Jackson HDO and HSO Between Bearings Pump

Byron Jackson HDO and HSO Pump Between Bearings Pump

Byron Jackson HDO and HSO Pump Between Bearings Pump

A multistage, HDO and HSO Between Bearings Pump consists of an axially split double-volute, opposed-impeller inner case and a radially split double-case pump. Ideal for applications requiring medium to high pressures. The Flowserve HSO/HDO high pressure multistage pump is a unique member of the double-case barrel pump family and it is available in both General Purpose and Special Purpose versions. It has more than a thousand units installed. In many circumstances, the HSO/HDO volute-style barrel pumps exceed API 610 (BB5) requirements, as specified by the client.

Byron Jackson HDO and HSO between bearings pump for reliable multistage and double-case industrial applications

Special purpose HDO and HSO Between Bearings Pump are the finest alternative for applications that require maximum dependability.

Apart from delivering hydraulic balance, these Special Purpose design pumps place a high value on dependability and longevity.

Typical Application

- Water injection

- Pipeline

- Amine feed

- Hydrocarbon charge

- Ethylene feed

- Acid gas reinjection

- CO2 injection

- Hydraulic power recovery turbine

Benefit

- A large selection of 31 reliable hydraulics that can be customized to fit unique needs.

- The ability to provide solutions and standardized designs with options to satisfy unique specifications

- Conforms to API 610 and additional standards desired by clients.

- Throughout the product’s lifespan, global access to local engineering and technical support

- A vast installed base, supported by substantial historical experience.

Configuration

- Single or double suction first stage execution (HSO/HDO)

- Power recover turbine (HDO-T/HSO-T)

- Coke crusher design (HSO-CK)

Related Industries

- Chemicals

- Specialty (Fine & Consumer)

- Biofuels

- Petrochemicals

- Oil & Gas

- Liquefied Natural Gas

- Upstream Exploration & Production

- Midstream Transportation

- Downstream Processing

- General Industries

Specification

- API 610 latest edition

- Any customer specifications

- Flows to 4,000 m³/h (17,610 gpm)

- Heads to 5,500 m (18,000 ft)

- Discharge pressures to 450 bar (6,525 psig)

- Temperatures to 450 ºC (840 ºF)

HDO and HSO between bearing pumps brochure

Optimize your processes with horizontal, multistage pumping solutions. Connect with us to learn more about the Byron Jackson HDO and HSO