ALP three-screw pump

Alfa Laval ALP Three Screw Pump

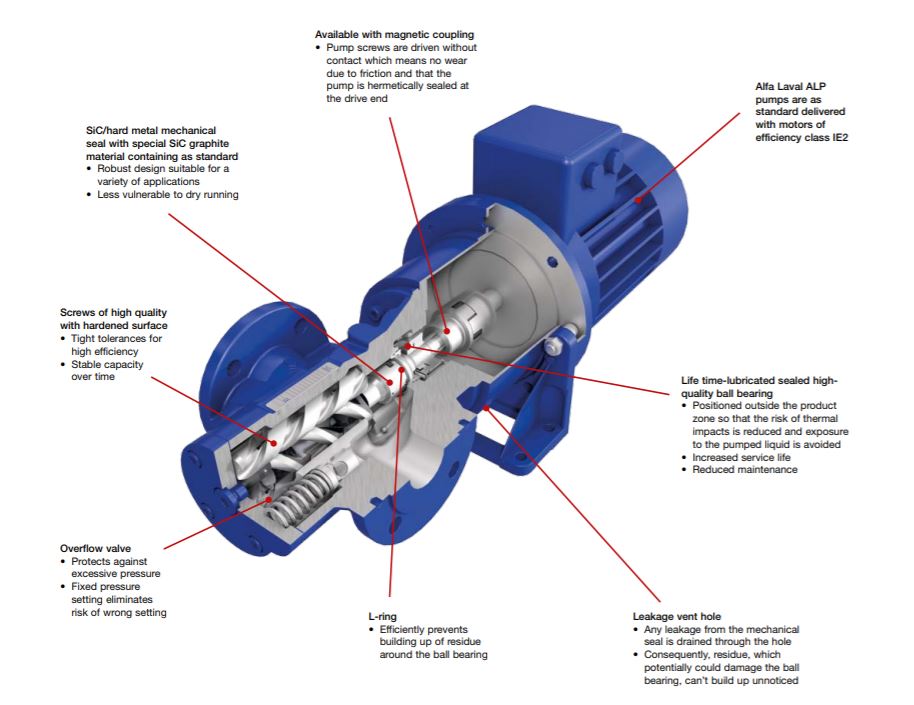

Alfa Laval ALP three-screw pumps are developed for lowest operating cost and highest reliability with specific focus on the marine industry. ALP is the obvious choice for handling of fuel and lubricating oils.

Compact and reliable design

ALP pumps are characterized by a compact design consisting of few components reducing the complexity of the pump using less spares and easing the handling. Furthermore, screws of hardened material enable tight internal tolerances which will ensure stable pump capacity over time.

Designed for low/lowest cost of ownership

A superior and fully tested shaft seal design optimizes the lubrication of the seal faces and improves air evacuation. The seal chamber is built to efficiently prevent building up of residue. This combined with the use of a high quality ball bearing, positioned outside the product zone reduces the risk of thermal impacts and avoids exposure to the pumped liquid. Maintenance requirements are reduced to a minimum.

User-friendly design

Very simplified disassembly and assembly of the pump enable easy and quick inspection, maintenance and service.

Magnetic drive version

The ALP pump range is also available in a magnetic drive version. The magnetic coupled design eliminates the risk of any leakage and a seal-less design reduces maintenance to a minimum.

Applications

The ALP pump is optimized for mineral oil applications and developed with a specific focus on marine and industrial

applications. Typical marine and industrial low pressure applications are:

- Supply and circulation of fuel, ranging from gas oil to heavy fuel oils

- Transfer of fuel oil on board ships, in power stations and oil facilities

- Oil circulation in hydraulic systems

- Lubricating oil circulation for cooling and separation

- Circulation of lubricating oil for diesel engines, gearboxes etc.

Benefits

Key benefits of the ALP pump design are:

- Minimized life cycle cost

- Low maintenance

- High quality

- Environmentally friendly

- High volumetric efficiency

- High energy efficiency

Technical data

Materials

- Pump casing: Nodular graphite iron, EN-GJS-400

- Screws: Nitration-hardened steel, 1,7139

- Seal faces, mechanical seal: SiC/hard metal

Port connections

- Flange SAE J 518/ISO 6162, PN16, at the top (ALP0015–0085) or in inline configuration (ALP0100–0280).

Motors

According to the IEC metric standard:

- 2 poles = 2,900/3,500 rpm at 50/60 Hz

- 4 poles = 1,450/1,750 rpm at 50/60 Hz

- 6 poles = 950/1,200 rpm at 50/60 Hz

- IP55, insulation class ICLF, efficiency class IE2

Design

ALP pumps are characterized by a compact design consisting of few components reducing complexity of the pump and easing the handling. Pump screws of hardened material enable tight internal tolerances ensuring stable pump capacity over time. The shaft seal design optimizes the lubrication of the seal faces and improves air evacuation, while the seal chamber is built to efficiently prevent building up of residue. This combined with the use of a high quality ball bearing, positioned outside the product zone, reduces the risk of thermal impacts and avoids exposure to the pumped liquid. Thus, maintenance requirements are reduced to a minimum.

The basic principle of a the ALP screw pump is that the turning screws isolate fluid and convey it. The conveyance thus takes place through the axial displacement of closed volumes.

Operating principle

Three-screw pumps are rotary positive displacement pumps. By the meshing of the three rotating screws and the enclosing pump casing, the displacement effect is created. The screws are radially supported by the sliding contact in the casing, which requires lubrication by the pumped liquid. The axial support of the main screw is carried out by a ball bearing.

The pump is equipped with an internal relief valve which will limit the differential pressure and protect the pump from excessive pressure. On the Alfa Laval ALP pumps the valve setting will be fixed at a specific opening pressure to avoid any risk of wrong pressure setting after installation.

Design

The Alfa Laval ALP pump is designed to ensure stable pump capacity over time. Casings are of nodular graphite iron, EN-GJS-400, and screws are of nitrated steel 1.7139. High quality mechanical seal of special SiC graphite material as standard

The fact that screws as standard are of hardened material is a parameter of decisive importance to anyone looking for a three-screw pump characterised by reliable performance.

Advantages of the ALP three-screw pump design:

- Low lifecycle cost

- Long life time and low maintenance

- Compact design

- High capacity at limited space

- High efficiency

- Low noise

- Low pulsation

- Pumping without violent turbulence

- Very good suction conditions (NPSH)