Alfa Laval SB Self-cleaning CO2 valve

Scandi Brew (SB) Self-cleaning CO2 valve

Scandi Brew (SB) Self-cleaning CO2 valve

The Alfa Laval SB Self-Cleaning CO2 Valve is a self-regulating valve that controls the flow of carbon dioxide through tank top systems and other. This valve that ABS offers is designed for use in the brewery, food, dairy and beverage industries, this combined gas escape/supply valve makes it easy to vent or pressurize the vessel. The valve can be integrated with a SCANDI BREW® tank top system.

Related Industries: Food Processing, Beverage Processing

Safe, reliable operation

The straightforward design of this gas management valve, featuring an internal polypropylene valve body and stainless steel spring, provides long-lasting operation. By minimizing the risk of overpressure or underpressure, the valve contributes to safe, reliable operation and maximum uptime.

Hygienic self-cleaning valve

Manufactured of AISI 316L stainless steel, the valve features a special drilled opening in the valve body, which effectively cleans all valve parts during Cleaning-in-Place (CIP). This minimizes the risk of contamination. Alfa Laval 3.1 traceability certification is also available upon request.

Construction

The valve consists of an AISI 316L stainless steel valve housing, spring, plug and EPDM seal. The valve housing consists of two components held together by a threaded connection. Inside there is a valve body made of polypropylene and a stainless steel spring to keep the body in open position.

The valve is typically positioned as an integrated part of the gas/CIP pipe at the top plate. It can be mounted at an angle of 45° (maximum) to the ideal vertical position. It can also be integrated with a SCANDI BREW® tank top system.

Operating principle

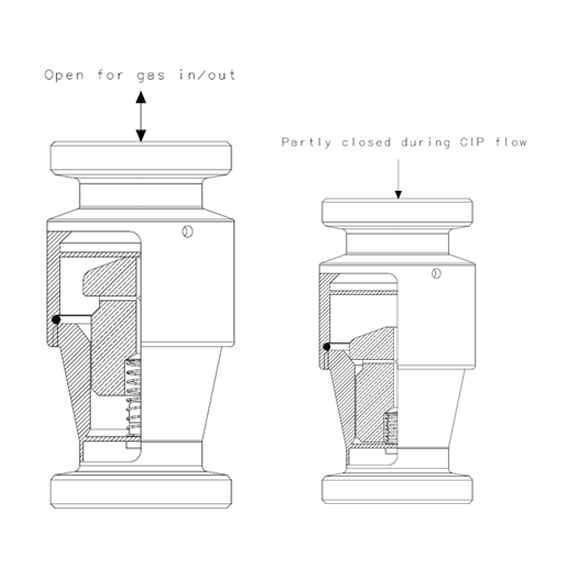

The stainless steel spring forces the valve body open, enabling the full flow of gas to pass through the valve in both directions. To force the valve body into closed position, CIP fluid flows in a countercurrent direction against the spring. Due to the force of the liquid, the valve closes. A special drilled opening in the valve body ensures hygienic cleaning of all valve parts.

Concept

Combined gas escape/supply valve to be used in tank top systems

and other applications for easy gas flow, allowing venting as well as

pressurizing of vessel through the valve. Partly-closed for CIP liquid

to be cleanable and self-draining.

Working Principle

The internal polypropylene valve body is force opened by a stainless

steel spring, thus allowing full gas capacity through the valve in both

directions. By introducing CIP flow against the spring force, the internal

valve body will be moved to a closed position.

The CIP liquid will close the valve but a special drilling of the valve

body ensures cleaning of all valve parts. Depending on valve size, this

CIP flow is approx. 800-900 l/h.

Standard Design

The valve housing consists of two parts held together by a threaded

connection. Inside there is a valve body and a spring to keep the body

in open position. The valve body is drilled to ensure internal cleaning of

the valve during CIP.

The valve is typically positioned as an integrated part of the

gas/CIP-pipe at the top plate. It can be mounted at an angle of

maximum 45° to the ideal vertical position.

TECHNICAL DATA

Maximum gas flow (both directions) at max. 0.1 bar ?P

Size …………….. Flow (m³/h)

1”/DN25 . . . . . . . . . . . . . . . 25

1½”/DN40 . . . . . . . . . . . . . 50

2”/DN50 . . . . . . . . . . . . . . . 150

2½”/DN65 . . . . . . . . . . . . . 250

3”/DN80 . . . . . . . . . . . . . . . 450

4”/DN100 . . . . . . . . . . . . . . 600

PHYSICAL DATA

Materials

Steel parts: . . . . . . . . . . . . .EN 1.4404 (AISI 316L) with 3.1 cert.

Product wetted seals: . . . . . .EPDM

Product wetted polymers: . . . .Polypropelen

Connections

Weld end acc. DIN 11850

Weld end acc. ISO 2037

Unions DIN 11851

Hygienic – Unions DIN 11853

Clamps ferrule ISO 2852