Enquiry

|

Alfa Laval |

Other Maker |

| Cover |

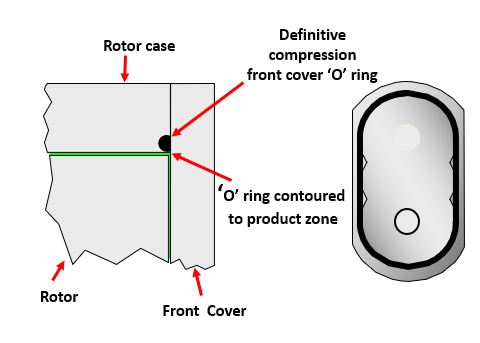

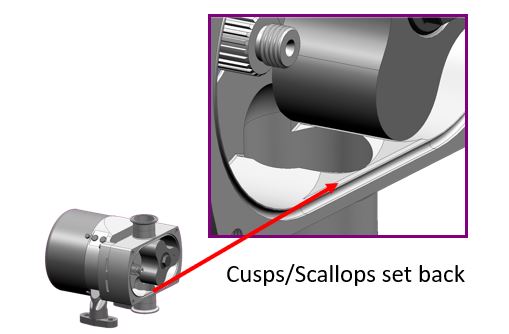

- This reduces the risk of process contamination, whilst improving product quality.

|

- Front cover o-ring not profiled on cusps or rotor bore, which is unhygienic.

- O-ring groove is square-cut into front cover. Apparent poor finish will create bug trap.

|

| Rotor |

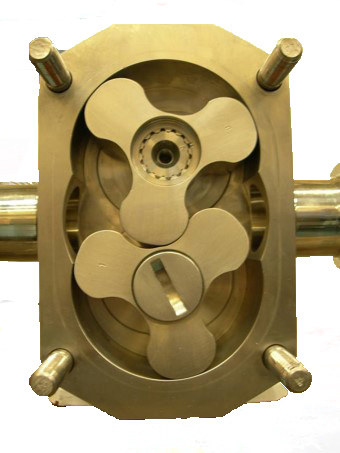

- Exchangeable position 02 rotor and easy to replace new rotors.

|

- Rotors marked “0” and “1”, corresponding to marks on shaft spline for positional assembly. Difficult to see when maintaining pump in site.

|

| Gear Box |

- The OptiLobe pump range has a universal gearbox design with the flexibility of mounting inlet and outlet ports in either a vertical or horizontal plane, by simply changing the foot position.

|

- Gearbox is not universal. Vertical porting option is only possible if using a different gear case.

|

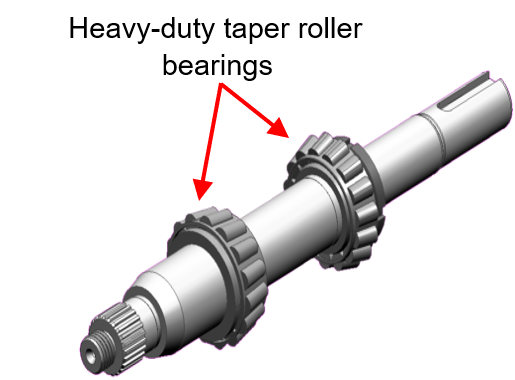

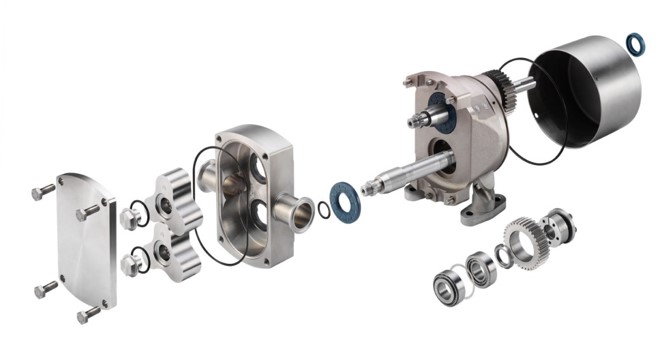

| Taper Roller Bearings |

With Heavy duty taper bearings with extended L10 life:

- allow for 20,000 hours minimum pump operation before replacement

- optimised axial load transmission

- reduce pump maintenance cost

- increase process up-time

- increase pump life-time

|

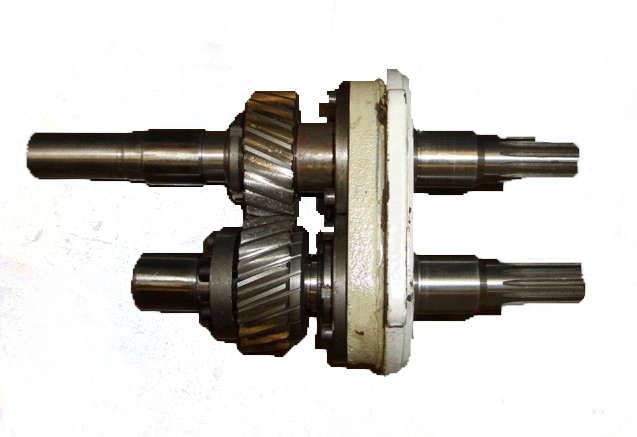

- Shafts were held in a “cartridge assembly”

- Timing gears located between front & rear bearings. Front bearing (not visible) is single ball bearing on all models – very weak design, suitability on arduous duties questionable!!

|

| Bearing Housing |

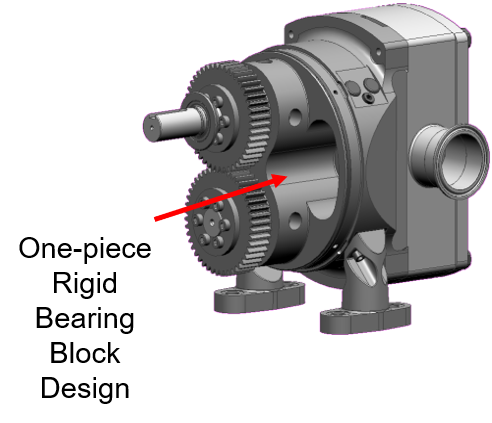

- One piece bearing housing gives stable shaft retention within rigid construction providing for greater pump durability under operation, extending pump life-time

|

|

| Component Interchangeability |

Full spare part component interchangeability allows:

- pump build repeatability

- consistent pump performance, leading to simplified pump servicing, reduced process down-time and less process variance

|

- Component interchange-ability questionable.

- Requirement for either new rotor, shaft or sleeve will mean pump clearances must be reset.

- Rotor nuts come off easily.

|

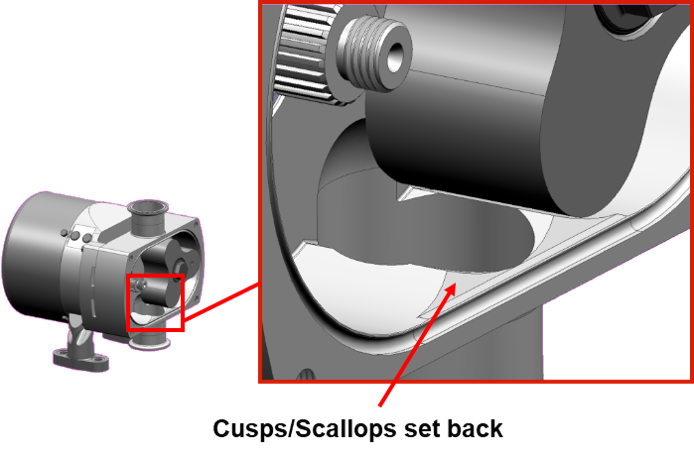

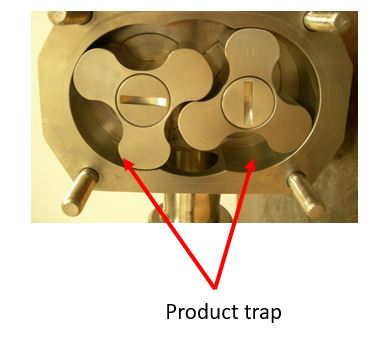

| Drain-ability |

Cusps/Scallops:

+running cost

+Minimised product degradation

Cusps/Scallops set back :

+Minimal product retention

+Minimised product degradation

|

|

Should you need any further information, please do not hesitate to contact our engineers.

Enquiry