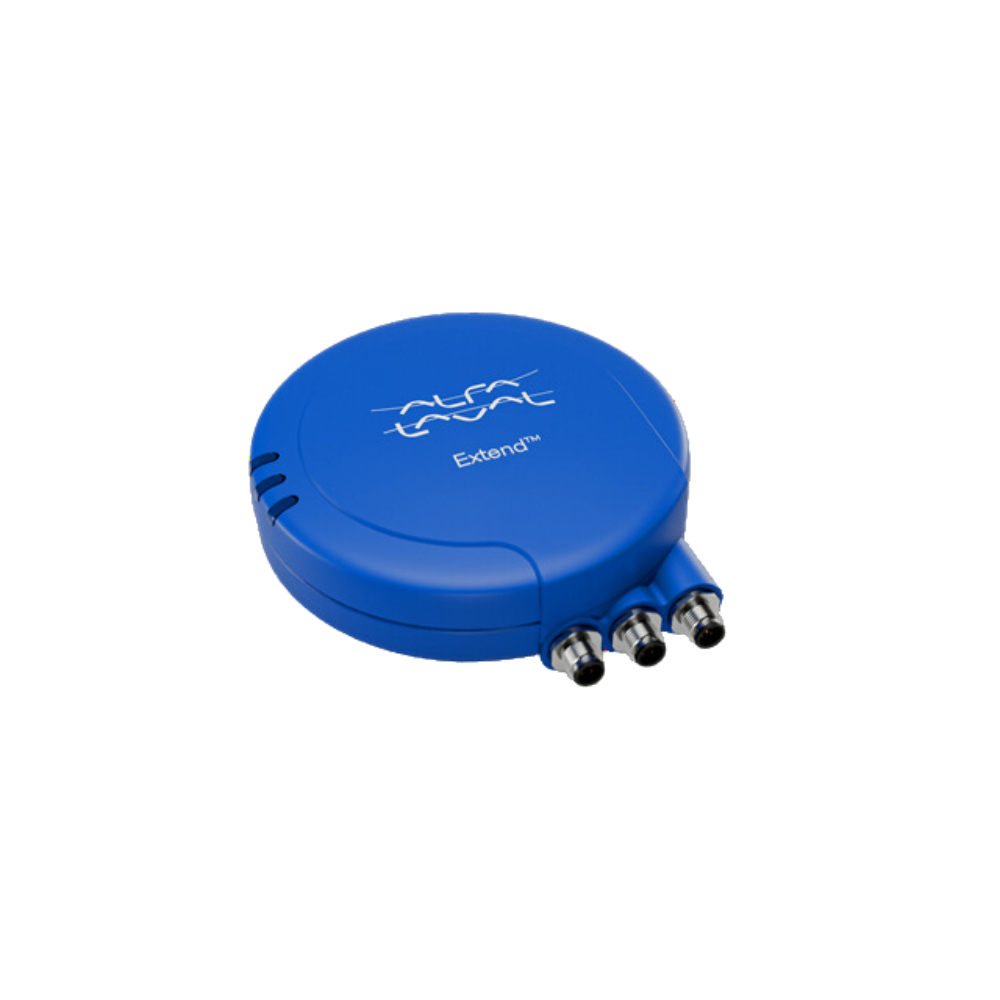

Alfa Laval Extend

Alfa Laval Extend

Alfa Laval Extend

Alfa Laval Extend is a revolutionary, plug-and-play heat exchanger accessory designed specifically for the dairy industry. ExtendTM is simple to install and increases the critical cleaning interval by 50% while reducing biofilm build-up by up to 99%, resulting in significantly increased production line uptime. Any plate heat exchanger will fit Alfa Laval Extend, making it a versatile solution for the sector.

Push the CIP critical limit to boost productivity with minimal effort.

- Extending cleaning intervals helps to increase output.

- Use less water and produce less wastewater.

- Reduce energy and cleaning chemical use.

Applications and Industries

Cheese processing

Alfa Laval’s components ensure moderate and efficient heat treatment and pumping, which is required for optimal quality and productivity.

Milk and cream processing

Milk and cream processing include a wide range of products including cream, white milk and produced flavourings. Alfa Laval’s sanitary elements maximise uptime while consuming less energy.

Butter and spread processing

Alfa Laval components can handle everything from separation and pasteurisation to ripening and churning in the butter and spread manufacturing process.

Whey, casein and lactose processing

Alfa Laval sanitary equipment offers a wide range of membranes for separation and concentration, facilitating end-product diversity and is specifically developed to fulfil the unique requirements of whey processing.

Yogurt and cultured milk processing

The rapidly increasing markets for cultural commodities hold great promise.

Alfa Laval’s whole line of sanitary components promotes inventiveness, adaptability and efficiency, all of which are necessary for success.

The Alfa Laval ExtendTM electrical pod is expertly engineered to connect the pasteurizer’s input and exit pipes. It prevents bacteria from adhering to the surface by applying a tiny current across the plate pack. This innovative system, installed by internal engineers without disrupting production, operates without the need of chemicals, coatings or product contact.

Alfa Laval Extend Video Information

Enhance uptime and efficiency with Alfa Laval Extend. Contact us today to learn more!