Alfa Laval Contherm Scraped Surface Heat Exchangers

Alfa Laval Contherm Scraped Surface Heat Exchangers

Contherm scraped-surface heat exchangers are designed for heating and cooling operations in the continuous and semi-continuous processing of many food, health, and beauty aid products. Contherm units are specially designed for applications where products are sticky, viscous, or have high solids content that are more difficult, if not impossible, to heat with other standard methods of heat transfer.

The wide variety of sizes and configurations allow Alfa Laval to meet the requirements of almost any application.

MODELS

- Contherm

- Contherm Core

- Contherm Select

- Contherm Max

- Contherm Evaporator

- Contherm Max Evaporator

Related Industries:

Processed Foods, High-Acid Foods, Dairy, Beverages, Home & Personal Care, Chemical

Many prepared food products would quickly foul normal types of heat exchangers, because they’re viscous or sticky, contain particles or alter state when heated.

The new generation of Contherm scraped-surface heat exchangers from Alfa Laval is updated with four new performance enhancements that extend the capabilities of the Contherm range. This means enhanced food safety initiatives, even more gentle treatment of the product and improved resistance to wear and chemical corrosion. An upgrading service named, ConthermFlex, is also available. This gives customers with old scraped surface technology an opportunity to upgrade their equipment.

Finally, there’s a newly developed, larger Contherm 6 x 11 with 15 % more surface area and up to 25 per cent more capacity than traditional sizes.

-

new blade materials with improved physical properties compared to traditional blades. These include a unique detectable polymer that enhances food safety and food security initiatives.

-

a new three-inch tangential head, designed specifically for sanitary and food-processing applications, improves product quality by treating it more gently. It is available as an option for new Contherm heat exchangers or as a retrofit.

-

the new Alfaloy cylinder coating is a thin diamond-impregnated material that offers improved resistance to wear and chemical corrosion. Alfaloy is a cost-effective, FDA-compliant material that extends the service life of the Contherm’s other components.

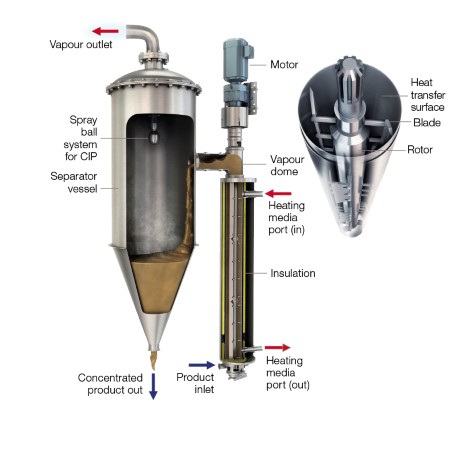

Convap evaporation module

The Contherm SSHE can be modified to form the Convap evaporator, which is particularly suited to concentrating viscous products. The system normally operates under vacuum. The entrainment separator connected to the SSHE by means of a specially designed vapor head allows the separation of the concentrate from the vapor phase.

APPLICATION

The Contherm™ scraped-surface heat exchanger (SSHE) has found use within many different processes and applications for manufacturing food, chemicals, pharmaceuticals, cosmetics, health, and beauty products. It is particularly suited for processing viscous, heat sensitive, sticky, or chunky (containing particulates) products that are to be pumped. It can be used in a broad range of processing environments, including: aseptic, heating, slush-freezing, sterilization, cooling, pasteurization, crystallization, and phase change.

DESIGN

The Contherm is designed to comply with the most stringent industry standards. USDA and 3-A hygienic design documentation is available for special executions. The Contherm is manufactured according to ASME and PED. Other pressure vessel codes are available on request. The Contherm SSHE can operate with a large flexible range of media types, such as steam, thermal oil, water, glycol, brine, Freon™, ammonia, and other liquefied gas refrigerants.

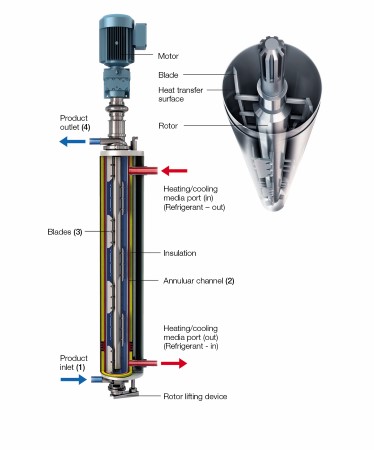

The standard execution is vertically mounted on a column. The column needs to be secured to either a wall or the ceiling. The rotor is placed on ball bearings and is driven by an electrical motor, which is installed on the upper end of the unit. Mechanical seals at each end of Contherm prevent product leakage and external contamination. Rotating scraping blades are secured to pins welded to the rotor. A hydraulic lifting device provides an easy way to lower the rotor and blades for maintenance and inspection. Tangential inlet/outlet ports provide gentler handling of the product, resulting in better product integrity and quality by allowing product to enter and exit cylinder in same direction as the turning rotor.

SPECIFICATIONS

| Working Temperature | Product side | -30°F to +338°F |

| Media side | -30°F to +338°F | |

| Maximum Working Pressure | Product side | 300 psig and full vacuum |

| Media side | 250 psig | |

| Connection | Product side | 2.0 inch DIN, Tri-Clamp®, SMS, other 3.0 inch DIN, Tri-Clamp®, SMS, other |

| Media side | 2.0 inch upper – NPT or flange 1.5 inch upper – NPT or flange |

WORKING PRINCIPLE

Product enters the cylinder through the lower product head and flows upwards through the cylinder. At the same time, the heating/cooling media travels in counter-current flow through the narrow annular channel between the heat transfer wall and the insulated jacket. Rotating blades continuously remove product from the cylinder wall in order to ensure uniform transfer of heat between media and product. An optional coil in the annulus increases media velocity, adding to the heat transfer efficiency. Product exits the cylinder through the upper tangential port. On start-up, air is completely purged from the Contherm. At the end of a processing run, the product can be drained or “chased out” by water resulting in minimal product loss.

Scraper configuration, rotor diameter, and rotor speed can be varied to suit the properties of the particular product flowing through the cylinder. Numerous Contherm configurations are available. Call CSI to discuss customizing a Contherm unit by selecting the appropriate materials, features and options to meet your exact requirements.

FLOW RATE

The Contherm’s maximum flow rate is application specific and determined by the temperature program, nature of the product, and type of duty.

MATERIALS

The heating surface is made in 316L stainless steel, honed to a very high finish on the inner surface. The scraping blades are made of Alfalon® III, Nylon, and Teflon material. Seal options are single carbon mechanical, carbon flushed / aseptic, hard face, and hard face flushed / aseptic. Suitable materials will be selected for special applications.

OPTIONAL FEATURES

The following optional design features are available: Alternative mounting configurations, including a horizontal option for use in facilities with limited ceiling height. Control panel with automatic maintenance status feature to prevent product freezing if flow is interrupted. Refrigeration (accumulator) or heating/cooling valve packages. Rotors in different sizes: 3 inch diameter, 4 inch diameter, 14.5 inch diameter, or 5 inch diameter. 27 barg product-side pressure rating is available.

How the Contherm scraped surface heat exchanger works

In scraped-surface heat exchangers, the product enters the cylinder at the bottom and flows upwards. The heating or cooling medium travels in a counter-current flow through a narrow annular channel.

Rotating blades continuously remove product from the cylinder wall to ensure uniform heat transfer to the product. The product enters the cylinder in a corkscrew pattern in the same direction as the rotating part. This preserves product quality by providing a larger flow area, gentler product handling and reduced pressure drop across the inlet.The food product finally leaves the cylinder at the top.

Both product flow and rotor speed can be varied to suit the particular properties of the product in the cylinder.

Rental units are also available. For reasons of confidentiality, if you prefer to carry out processing trials using Contherm in your own plant and with your own personnel, we can offer you a Contherm test unit on a rental basis along with qualified Contherm personnel during start-up.

How the Convap scraped surface evaporator / concentrator works

Just as in Contherm units, product is pumped into the lower end of the Convap heat exchanger cylinder. The heating/cooling media flows in the annular space between the heat transfer wall and the insulated jacket. Mechanical agitation, provided by the revolving blades, creates the convection conditions essential for efficient heat transfer.

The scraping blades continuously remove the thin product film from the precision-finished cylinder wall. The centrifugal action of the Convap rotor, driven by a motor on the upper end of the unit, spins the heavier liquid droplets toward the cylinder wall. This action assures a continuous re-wetting of the heat transfer surface and prevents product burn-on.

Experience seamless processing and exceptional results with Alfa Laval Contherm scraped surface heat exchangers. Contact us today to elevate your operations!