Single Seat Valve:

Unique Single Seat Valves Series (Unique SSV)

Ideal for uninterrupted production in a broad range of hygiene-critical applications, Unique single seat valves are pneumatic seat valves used to shut off or change product flow.

Versatile and reliable single seat valve

Alfa Laval Unique single seat valves (SSVs) are robust and reliable pneumatic seat valves that are supremely reliable and versatile.

Modularity provides cost-effective and nearly endless possibilities for purpose-built seat valves that meet high standards of hygiene and aseptic compatibility. Configure the Unique SSV valve bodies, plugs and actuators to meet virtually any requirement.

Superior valve process safetyIn the US and Canada the Unique 7000 corresponds to the Unique single seat valve.

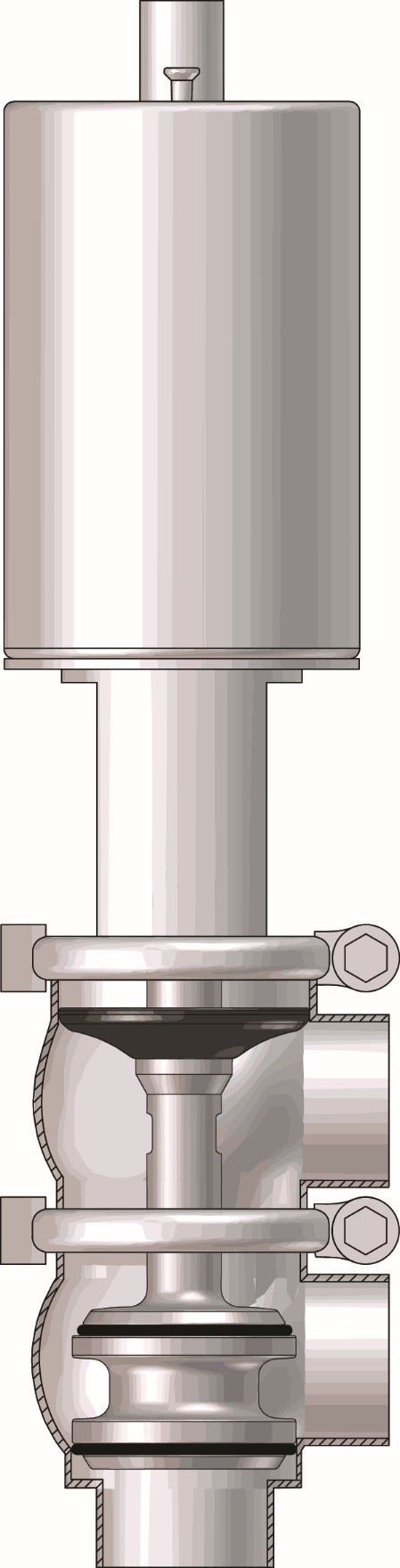

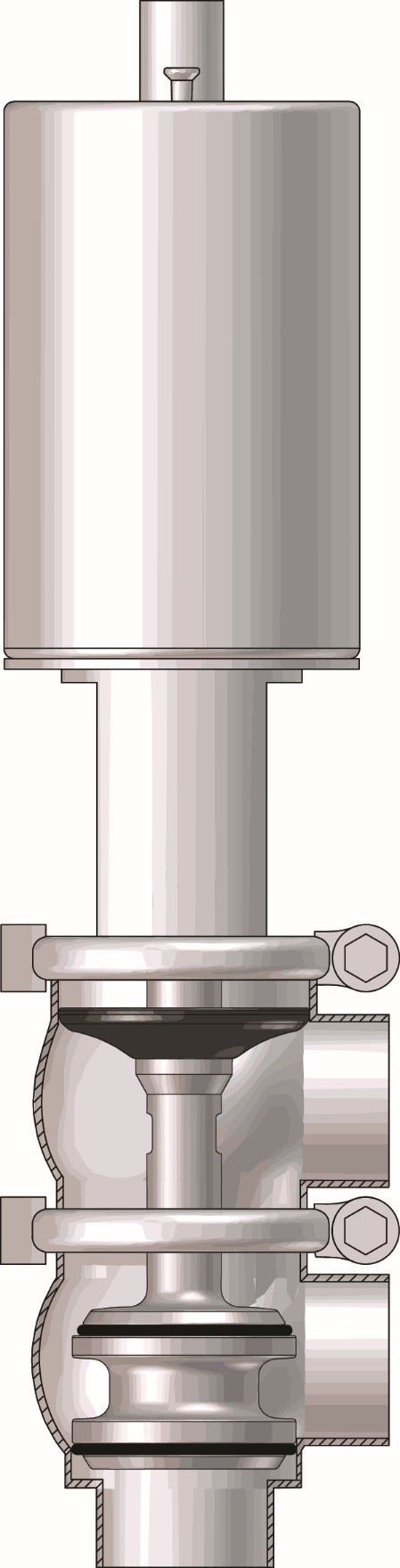

The Unique SSV range is built on a proven modular platform used on more than a million valves in service worldwide. Pressed from a single stainless steel disc, the valve body is extremely strong and durable, thus ensuring production safety. The enhanced performance of the actuator makes operation safer and more efficient.

Exceptional valve hygiene

The Unique SSV range is engineered to provide excellent hygiene and cleanability. With a surface finish of Ra ? 0.8?m, the smooth, weld-free valve body eliminates crevices that can trap bacteria. The design of the plug supports enhanced cleaning-in-place capabilities, and a double-acting lip seal that minimizes any risk of cross-contamination.

Alfa Laval Unique SSV valves meet most hygienic standards requested in the dairy, food and beverage, and personal care industries. The Unique SSV range is EHEDG-certified and authorized to carry the 3-A symbol. The range also provides full traceability in compliance with the EU Food Regulation 1935/2004.

Greater valve durability

To ensure high sealing quality, the Unique SSV range features defined compression of the O-rings with metal-to-metal contact between plug and seat. This significantly reduces wear and extends valve service life. The standard Unique SSV is supplied with a non-maintainable actuator that has a five-year warranty.

Low total cost of ownership

Thanks to its straightforward, reliable design, the Unique SSV range provides long service life, reduced product loss, greater product safety and more processing uptime. Few moving parts reduce service requirements and inventory costs. More effective CIP procedures with reduced cleaning cycles and, subsequently, the reduced use of cleaning fluids, water and utilities also contribute to the Unique SSV’s low total cost of ownership.

Construction

The Alfa Laval Unique SSV range consists of one, two or three valve bodies, plug, sealing, actuator and clamp ring.

Operating principle

The Alfa Laval Unique SSV is an air-operated seat valve that is remotely operated by means of compressed air. The valve generally has two working ports for air supply in and for process air supply; for changeover valves, a third port is required.

Unique SSV Aseptic

Fully modular with the proven design of the Unique SSV the aseptic single seat valve is equipped with a hermetic sealing diaphragm that ensures true aseptic conditions during operation. It hermetically seals against intrusion from the atmosphere and ensures full protection against the effects of microorganisms

With a “sandwich construction” of PTFE on the product side, EPDM and an enforcing mesh, the aseptic diaphragm is optimized to guarantee reliable performance and long lifetime. In open position the one-piece diaphragm is mechanically supported by the valve to reduce wear and increase endurance.

The Unique SSV Aseptic valve is available in both pneumatic and manual configurations.

Unique SSV Unique SSV

aseptic shut-off valve aseptic change-over valve

Options

- Fully maintainable actuator

- High-pressure actuator

- Product wetted seals in HNBR or FPM

- TR2 plug seal in PTFE for special applications

- Valve sensing and control devices, incl ThinkTop, ThinkTop Basic and IndiTop

- Fittings in accordance with required standard

- External surface finish 3-A bright

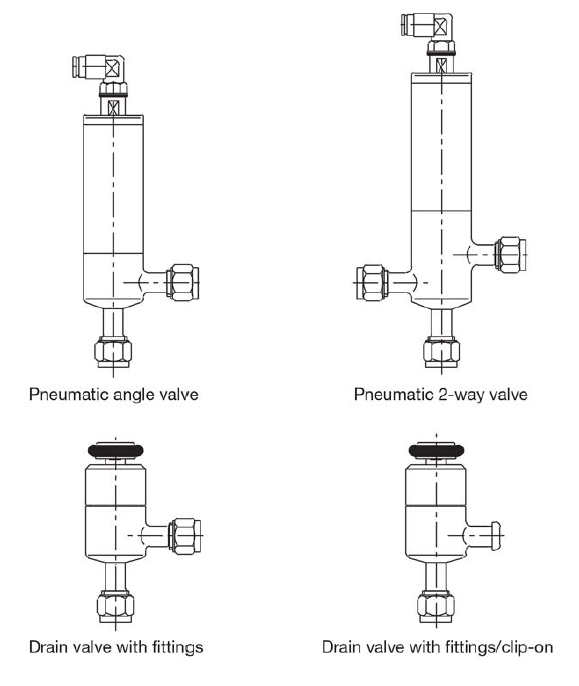

Unique single-seat valve range

The Unique SSV range comprises several purpose-built valve configurations. Modularity provides great flexibility to customize valves to your specific requirements.

|

|

Unique SSV valve (standard) for a broad spectrum of processing duties |

|

Unique SSV reverse-acting valve for use in applications where the flow direction does not allow the use of a standard Unique SSV valve to eliminate the risk of pressure shock. |

|

Unique SSSV small single seat valves for use in sampling, CIP and other contexts where only small flow rates are involved.

|

|

Unique SSV tank outlet valves for installations that open into the tank (reverse-acting version) or close up against the tank (standard version). |

|

Unique SSV ATEX valves for intrinsically safe operation in potentially explosive environments. |

|

Unique SSV Y-body valves for use in installations that involve flows with large particles and/or high viscosity, and where the focus is on particularly gentle treatment of products and flows.

|

|

Unique SSV long-stroke valves for use where larger openings are required to provide gentler, more effective flow control such as in installations with media or products that contain particles and/or suspended solids and for high-viscosity flows.

|

|

Unique SSV tangential valves for use in tank openings, horizontally mounted drains and for wherever space restriction make it difficult to install valves at other angles.

|

|

|

Unique SSV two-step valves for use in dosing, two-stage filling where the focus is on ensuring an exact volume or for draining of two pipes at the same time. Adjustable lifting height makes it possible to match specific volumes and quantities.

|

|

|

Unique SSV manually operated valves for shut off, tank outlet or straightforward regulating or dosing purposes that require small, relatively simple valves with many different options and features, including lockable handles.

|

|

Unique SSV RF valve is available in one size. Unique SSV RF comes with a fixed Kv value of 11 and a plug with almost linear characteristics. It is used for duties where regulating accuracy is essential.

|

|

|

ASEPTIC VERSION

Unique SSV aseptic valve for sterile process applications. A one-piece diaphragm provides hermetic sealing against intrusion from the atmosphere, ensuring full protection against the effects of microorganisms during processing.

The special diaphragm offers modularity as it can be used with a broard range of the Unique SSV configurations – including standard, tangential, two-step, manual and tank outlet valves. This modularity also support upgradability of already installed valves if the need arises to modify exiting process installations meeting the need of tomorrow…

The Unique SSV aseptic valve design offers a straight forward design with focus on product safety, sort sterilization time as well as fast and affordable replacement of service parts.

|

|

|

Unique Single Seat DN125 (5″) and DN150 (6″) valves are pneumatic seat valves in a hygienic and modular design offering a wide field of applications, for instance as a stop valve with two or three ports or as a change-over valve with three to five ports. These valves complement the Unique Single Valve family for large size installations in specific areas of your plant where size matter. |