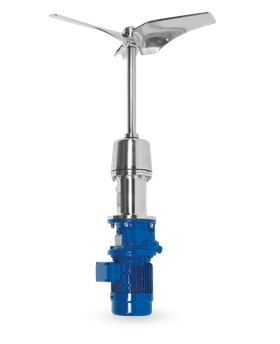

Alfa Laval ALB Agitator Bottom Mounted

The Alfa Laval ALB Bottom Mounted Agitator is a high-performance mixing solution designed for food, dairy, beverage, pharmaceutical, biotechnology and cosmetic industries. Whether for atmospheric or pressurized tanks, this agitator ensures optimal mixing performance with low energy consumption. It is also configurable for sterile and aseptic applications to meet strict industry standards.

Why Choose the ALB Bottom Mounted Agitator?

- Energy-efficient mixing with EnSaFoil impellers

- Low maintenance design for high productivity

- Customizable configurations for various industries

- Meets global hygiene standards (EHEDG, FDA, USDA, 3-A)

Comparing ALB vs ALTB Agitators

| Feature | ALB Agitator | ALTB Agitator |

|---|---|---|

| Design | Bottom-mounted | Bottom-mounted with extra efficiency |

| Application | General industrial use | High-efficiency, sanitary applications |

| Energy Efficiency | Standard | Enhanced for lower power consumption |

| Maintenance | Low | Ultra-low |

Q: What are the advantages of a bottom-mounted agitator compared to a top-mounted one?

A: A bottom-mounted agitator eliminates fluid dead zones, provides more uniform mixing, and reduces contamination risks in sanitary environments. Additionally, it consumes less energy while maintaining high-efficiency blending.

1. Energy-Efficient Design

- The EnSaFoil impellers reduce energy consumption by up to 80% compared to conventional designs.

- Optimized for low shear mixing, minimizing heat absorption.

2. Modular & Hygienic Construction

- Smooth surface design ensures easy cleaning and hygienic processing.

- Meets EHEDG, FDA, USDA, and 3-A standards for food and pharmaceutical applications.

3. Simplified Service & Maintenance

- Minimal wear and tear extends the agitator’s lifespan.

- Seal and bearing replacement without dismantling the tank saves time and costs.

The Alfa Laval ALB Bottom Mounted Agitator operates using a combination of energy-efficient impellers and controlled axial flow movement, ensuring optimal fluid dynamics. Unlike top-mounted agitators, the bottom-mounted design minimizes dead zones and promotes better product consistency.

Key Advantages of Bottom-Mounted Operation

- Higher Efficiency: Eliminates stratification issues, ensuring uniform product blending.

- Reduced Energy Use: The low-speed rotation combined with high-flow pumping action maximizes mixing power with minimal power consumption.

- Improved Hygiene: No additional shafts or components above the liquid surface reduce contamination risks in sanitary applications.

This makes the ALB Bottom Mounted Agitator an ideal choice for industries requiring precision and high cleanliness standards.

Industries Using the ALB Bottom Mounted Agitator

The ALB Agitator is engineered to meet the strict requirements of multiple industries, ensuring efficient mixing while reducing operating costs.

- Food & Beverage: Used in dairy, beverage, and sauce production to maintain consistent texture and uniform mixing.

- Pharmaceuticals: Ensures sterile, contamination-free blending of liquid ingredients for medicines and healthcare products.

- Chemical Processing: Handles corrosive, high-viscosity, and reactive fluids with precision, improving product stability.

- Renewable Energy & Waste Treatment: Helps in biofuel processing and industrial wastewater treatment, enhancing environmental sustainability.

Each industry benefits from optimized energy consumption, precise process control, and compliance with international hygiene standards.

Motor Options

- Motor size and speed: Customizable based on duty requirements.

- Standard motor type: IEC motor IP55 (other types available upon request).

- Paint finish: Standard RAL5010 coating.

- Voltage & Frequency:

- 3×380-420V, 50Hz

- 3×440-480V, 60Hz

- Other motor voltages and frequencies available upon request.

Gear Options

- Various gear types are available based on configuration.

- Standard gears are filled with normal synthetic or mineral oil.

- Optional food-approved oil available.

- Standard finish: RAL5010 coating.

ATEX Certification (Explosion-Proof Option)

- The ALB Bottom Mounted Agitator is available in an ATEX-certified version.

- Comes with a Declaration of Conformity for use in hazardous environments

Ordering Information

To ensure the correct size and configuration, please provide:

- Tank geometry

- Product properties

- Agitator application & process details

Enquiry forms are available to guide you in selecting the right agitator specifications.

Standard Design & Customization

The Alfa Laval ALB Bottom Mounted Agitator is designed for versatility and compliance with global industry standards. Due to its modular construction, it can be configured to meet the specific needs of various applications while adhering to:

- EHEDG, USDA, FDA, and 3-A standards.

- European & American industry regulations.

Configurable Design Elements

The agitator can be customized in the following areas:

- Drives: Drive unit + shaft support + shaft diameter

- Seal Arrangements: Oil trap + shaft seal type

- Shaft Length: Customizable based on tank size

- Energy Saving Foils: Propeller type + surface finish

- Additional Options: Other configurations available upon request

Each of these elements offers a range of options, ensuring the ALB Bottom Mounted Agitator is perfectly suited for your specific mixing application.

Get in touch with our team to learn more about how the Alfa Laval ALB Bottom Mounted Agitator can enhance your mixing processes. Let us help you find the right solution for your industry.