ST Mixer Seal

IntroductionFeaturesDocumentation

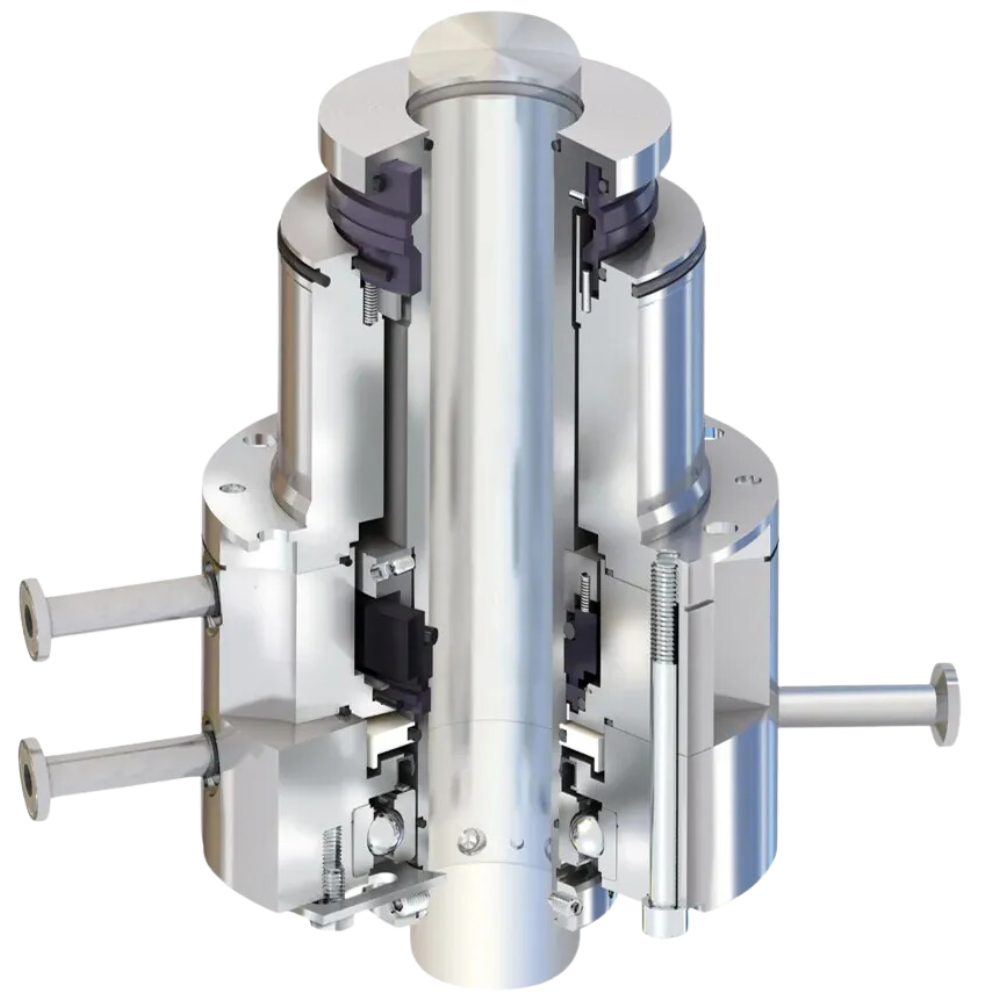

ST Mixer Seal

ST Mixer Seal are dual pressured mechanical seals that are cartridge-shaped and designed specifically for bottom entry agitators used in the pharmaceutical and biopharmaceutical industries. ST Mixer Seal are compatible with FDA-approved materials and USP Class VI polymers and they have been optimized for SIP/CIP applications

ST Mixer Seal Designed for Chemical and Pharmaceutical Applications

Benefit

- The modular cartridge construction, which includes and excludes bearings, as well as the liquid-lubricated and gas lift-off designs, offer a wide range of application possibilities.

- The balanced dual-pressurized design and FEA-optimized seal faces result in longer seal life by reducing wear and friction.

- The flexibility to reverse pressure and emergency sealing options allow for more reliable and safe operation.

- There are several options for steam cleaning applications, including a sanitary gland/debris catcher and a cooling flange.

Specification

- Standards: Can meet FDA requirements

- Size Range: 25 to 108 mm (1.000 to 4.250 in)

- Operating Parameters

- Maximum Barrier Pressure: 3.4 bar (50 psig)

- Maximum Temperature: 135C (250F)

- Maximum Speed: 4 m/s (13 fps)

Configuration

ST

Bottom Entry for Pharmaceutical Applications

Related Industries

- Chemicals

- Pharmaceutical

Mechanical Seals for Mixers and Specialty Equipment

Flowserve Seal Product Portfolio

ST Mixer Seal Installation Instructions

Optimize your sealing solutions with the ST Mixer Seal. Contact us to explore its benefits for your chemical and pharmaceutical operations.