Mixerpac Mixer Seal

IntroductionFeaturesDocumentation

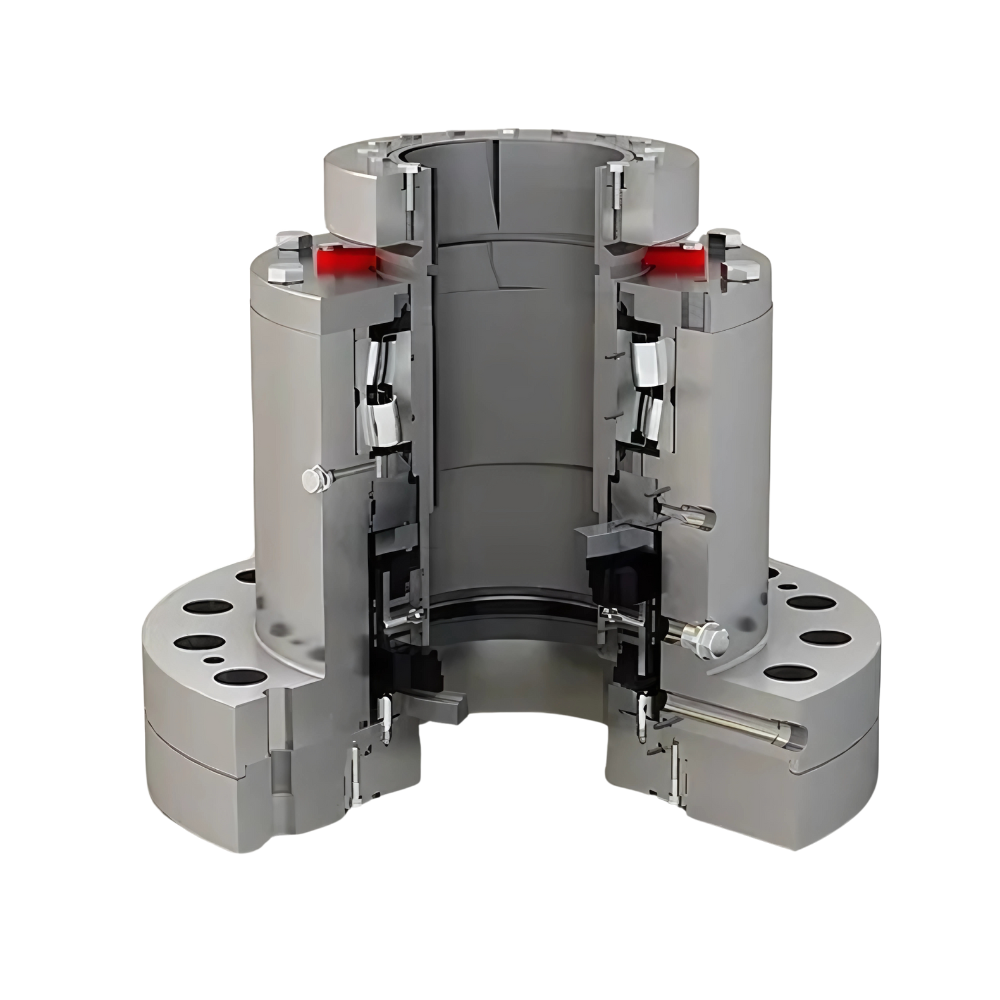

Mixerpac Mixer Seal

The Mixerpac range of customized and standard mixer seals can be installed in a number of top, side and bottom entrance combinations.

Mixerpac Mixer Seal for High-Performance Industrial Mixing Applications.

Benefit

- Modular cartridge construction with and without bearings, as well as liquid-lubricated and gas lift-off designs, offer a wide range of application options.

- The Mixerpac Mixer Seal lifespan is prolonged by the optimized seal faces and regulated dual-pressurized design, which reduce friction and wear.

- The provision of emergency closure options and reverse-pressure capability ensures reliable functionality and increased safety.

- There are numerous solutions for applications that require steam cleaning, such as a cooling flange and a sanitary gland or debris catcher.

Specification

- Press: vacuum to 250 bar (3600 psi)

- Temp: to 200°C (390°F)

- Speed: to 10 m/s (33 fps)

- Sizes: 25 to 365 mm (1.000 to 14.400 in)

Configuration

- Mixerpac 581

- High Pressure

- Mixerpac 587/588

- Horizontal Entry Seal

- Mixerpac 585/586

- Bottom Entry Seal

Related Industries

- Chemicals

- Basic (Organic & Inorganic),Specialty (Fine & Consumer), Biofuels, PharmaceuticalPetrochemicals

- Water

- Water Management, Wastewater, Agriculture & Irrigation

- Oil & Gas

- Downstream Processing

- General Industries

- Pulp & Paper, Steel & Primary Metals, Food & Beverage

- Mining

Flowserve Mixerpac Mixer Seal Product Portfolio

Attain optimum performance with the Mixerpac Mixer Seal. Reach out to us to see how it can improve your industrial mixing operations.