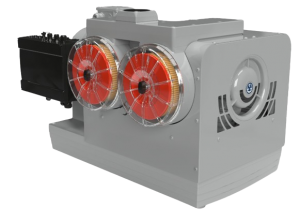

Becker Claw Vacuum Pump VARIAIR BCV Series

Becker VARIAIR BCV Series Claw Vacuum Pumps

Becker VARIAIR BCV Series Claw Vacuum Pump are medium vacuum, displacement pumps. The operation chamber of these claw pumps is 100% free of oil and contact. To achieve this, the claw-like rotors rotate within the compression chamber in opposite directions and are contactless. This makes the vacuum pump particularly low-maintenance. The Becker BCV claw technology ensures a high degree of efficiency and low energy consumption.

The frequency inverter integrated in the VARIAIR UNIT significantly enhances the performance data of each pumps. It matches the pump delivery exactly to customer requirements. Energy consumption is optimized and constant vacuum or pressure is guaranteed even where demand is subject to Variation or severe fluctuation. As no unnecessary blast or suction air is generated, (air discharge) noise is kept to a minimum. Dirt from the surrounding environment is kept out of the pumps via inlet filtration. “Gentle” pump start-up reduces strain on mechanical components and reliably extends their useful life. Variable Output ranges minimize the number of different types required, this also providing logistical advantages.

Each VARIAIR BCV Series Claw Vacuum Pump comes standard with:

- Built-in suction filter with clear cover

- Vibration isolators

- VARIAIR frequency inverter

Features

Becker’s BCV VARIAIR Series Claw Vacuum Pump comes with a series of highlighted features that showcases the functions of the pump in an industrial process;

- 100% oil-less operation chamber

- Air-cooled

- Non-contact compression

- Continuous duty rated

- Single shaft direct drive

- Compact design

- Variable frequency

- Internal filtration with clear cover

Benefits

Becker’s BCV VARIAIR Claw Vacuum Pumps comes with a line of benefits to better suit your application;

- No external filters needed

- Low maintenance, minimal maintenance costs

- Straightforward construction for fast and easy service on-site to reduce downtime

- Low energy consumption, low energy costs

- Quick visual check of filter status

| Volume Flow | Vacuum Absolute | Inverter Power | Hz | |

| VARIAIR BCV 100 | 120 m³/h | 50 mbar | 4 kW | 30…60 Frequency |

| VARIAIR BCV 150 | 180 m³/h | 100 mbar | 4 kW | 30…60 Frequency |

| VARIAIR BCV 300 | 325 m³/h | 150 mbar | 4 kW | 30….60 Frequency |

*Data sheet available upon request

Becker’s BCV VARIAIR Series, Claw Vacuum Pumps are suitable for an array of markets and applications.

Markets

- Secondary Packaging Industry

- Woodworking Industry

- Printing and Paper Industry

- Medical Industry

- Plastics Industry

- Environmental Industry

- Electronics Industry

- General Mechanical Industry

- Construction Industry

Applications

- Vacuum Fixing: Vacuum pumps and vacuum systems from Becker are the ideal solution for holding goods and components in place during production, processing and packaging.

- Pick & Place: Many modern production processes require the use of vacuum to transport, lift and place goods and materials, including feeders for printing, secondary packaging, and other automatic loaders.

- Evacuation: From food processing and packaging, to thermoforming and manufacturing, the removal of air or gas from a given space is one of the most wide ranging applications of the vacuum pumps and systems.

- Extracting: Vacuum pumps are used for a wide range of applications that require the removal of fluids, waste and air as well as various other materials.

- Pneumatic Conveying: Low pressure and vacuum solutions are perfect for transferring powders, granules, flakes and other small, dry, low bulk density products.

- Degassing: Vacuum pumps are the preferred solution for removing gasses, air, moisture, and vapour from processes materials like plastics, ceramic and pasta to improve the finished product quality.