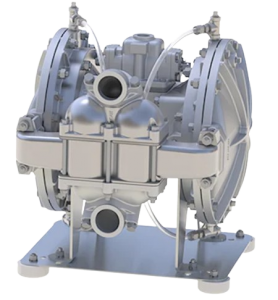

Sandpiper ST1½ & ST40 Metallic AODD Pump

Sandpiper’s ST1½ & ST40 Metallic AODD, Containment Duty Pump

Sandpiper’s ST1½ & ST40 Metallic Containment Duty AODD Pump were designed to handle highly corrosive and hazardous chemical fluid requirements. The containment duty pumps are designed with containment chambers, hydraulically balanced/coupled pumping diaphragm and driver diaphragm assemblies. The containment chambers are designed to accommodate visual, mechanical and low-voltage leak detection devices. The Containment Duty Pumps are constructed of materials such as Aluminum, Stainless Steel and Alloy C, with elastomer TPE (thermal plastic elastomers) and PTFE options in diaphragms and check valves.

Why use containment duty pumps?

Due to environmental concerns regarding corrosive or hazardous fluids escaping into the environment, a large portion of the time is required to clean up and recover lost materials. On top of the concerns, there will be downtime, lost productions, manpower, equipment replacement, disposal fees and fines can be excessive. Prevention of these leaks whilst handling these fluids allows for a more efficient operation and avoid the damaging effect of these toxic fluids’ exposure towards the people and the environment.

When the fluids that are considered important to the products escape into the environment the cost of these losses are significant as it is considered losing profit. Even non-toxic fluids such as water can create a hazardous environment towards the safety of the people working around the area surrounding the pump should a diaphragm fails. The Containment Duty Pump is able to prevent all these losses through its system by redirecting the fluid that breached the diaphragm towards a containment chamber that alerts its users through a visual indicator. The pump will be able to maintain its operations until the end of the processing time or until its scheduled maintenance.

Some of the features of the AODD Pump highlights the advantages of the pump in its industrial applications;

- The containment duty pump are designed to accommodate visual, mechanical and electronic leak detection devices.

- The durable, bolted construction of the ST1½ is superior to the clamped-band construction pump, providing exceptional leak-free performance.

- Sandpiper’s ESADS+ feature allows access to the complete Air Distribution System (ADS) without removing the pump from service.

- Repair or clean in 5 minutes (versus 55 minutes for competitors)

- ST1½ offers air-side interchangeability with Sandpiper’s HDB 1½ for reduced inventory costs.

- Sandpiper’s original ADS is fully interchangeable, repairable and inline-serviceable.

| Port Size | ST15:

1½” NPT ST40: 1½” BSP (Tapered) |

| Capacity | 0 to 106 gpm (400 lpm) |

| Air Distribution Valve | No-lube, no-stall design |

| Solids-Handling | Up to ¼” (6.3 mm) |

| Heads Up To | 125 psi or 289 ft. of water (8.6 bar or 88 meters) |

| Displacement/Stroke | .37 gallons (1.29 liters) |

| Max Operating Pressure | 125 psi (8.6 bar) |

| Shipping Weight | Aluminum:

99 lbs (46 kg) Cast Iron: 146 lbs (66 kg) Stainless Steel: 212 lbs (95 kg) |

There are various uses for the Containment Duty Pump as it is versatile in handling fluids that are required specific handling. Some of the industries it covers are as follows;

- Paint and Coating Industry & Printing Industry

- Resin Manufacturing

- Chemical Industry (Petrochemical)

- Oil & Gas Industry (Petroleum Refining)

- Chemical Industry (Metal Processing)

- Plastic & Polymer Industry (Packaging Industry)

- Water Treatment (Environmental Engineering)

- Agriculture Sector (Agrochemical Industry and Fertilizer Manufacturing)

- Food & Beverage Processing

- Plasticizers in Polymer Manufacturing