Alfa Laval Pressure Relief Valve

ABS offers Alfa Laval’s Pressure Relief valves to help you to prevent damage to the tank and help ensure safe operations.

Alfa Laval Valve Automations: Indication Unit, IndiTop, ThinkTop, ThinkTop Basic, ThinkTop D30, GreenTop

Scandi Brew (SB) Pressure Relief Valve

Scandi Brew (SB) Pressure Relief Valve

To prevent damage to the tank and help ensure safe operations, ABS offers the Alfa Laval SB Pressure Relief Valve protects a pressurized tank during an overpressure event. It is designed for hygienic processes in the brewery, dairy, food and beverage industries. The valve can be integrated with a SCANDI BREW® tank top system.

Related Industries:

Processed Foods, Dairy, Beverages, Home & Personal Care

Effective pressure relief

This pressure relief valve removes excess liquid that creates overpressure in the tank due to overfilling. When pressure in the tank exceeds a preset value, the pressure relief valve opens to vent fluid in the event of liquid overfilling, and closes when the tank pressure has returned to a safe level.

Easy-to-clean hygienic design

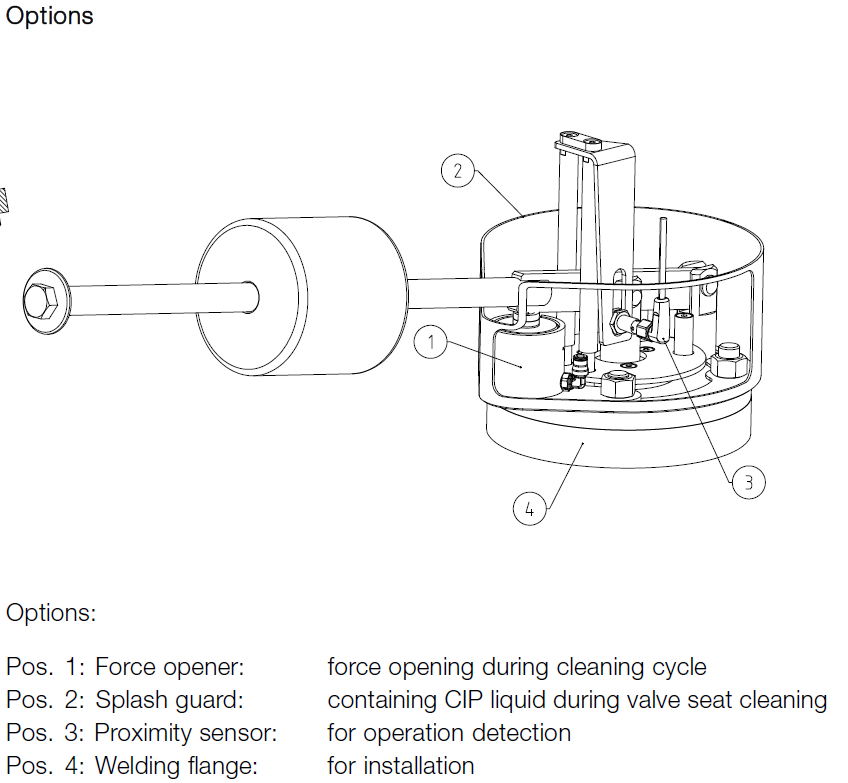

Few moving parts and smooth, crevice-free stainless steel surfaces make this valve easy to clean. When the valve is in closed position, it is cleaned as part of the routine Cleaning-in-Place (CIP) cycle. For thorough cleaning of the valve seat, an optional pneumatic force opener and a splash guard is available.

Construction

The Alfa Laval SB Pressure Relief Valve is a dead weight safety valve. It is compliant with PED 97/23/EC, EN 4126-1 and EN 764-7 and is available in two versions:

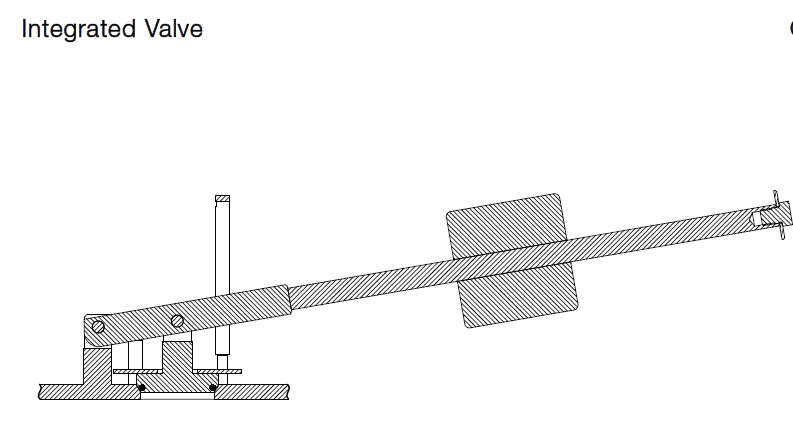

- Integrated with a SCANDI BREW® tank top system

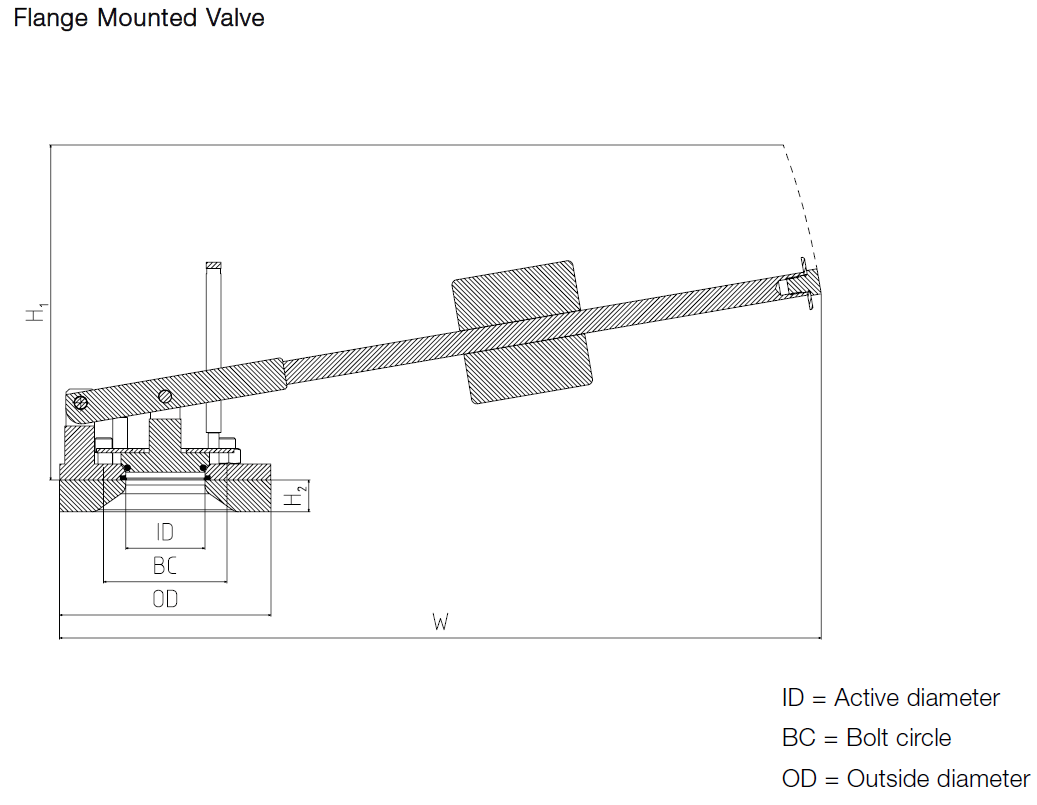

- Mounted on its own counter flange

Operating principle

The pressure relief valve is delivered with the counterweight set and locked at the preset pressure that meets the customer’s requirements for opening pressure. When pressure in the tank exceeds the preset opening value, the valve relieves the excess pressure.

The preset opening pressure must be set at a value that is above the tank working pressure: 0.1 bar above for working pressures <1 bar, and 10% above for working pressures ? 1 bar. The valve should be seated horizontally. A maximum inclination of 10° is acceptable, but the lever arm must then point inward toward the centre of the cylindroconical tank top.

Cleaning-in-Place (CIP)

The valve is cleaned in closed position by the tank cleaning head. However, this does not include cleaning of the valve seat. To include the valve seat as an integral part of the cleaning cycle, an optional pneumatic force opener and optional splash guard are available.

Concept

The Pressure Relief Valve is used for minimizing the risk of damage

to tanks due to liquid overfilling.

Working Principle

The Pressure Relief Valve is delivered with counter weight set and

locked to suit customer requirements regarding opening pressure.

When pressure in the tank exceeds the preset opening value, the valve

relieves the excess pressure.

Standard Design

The Pressure Relief Valve is available in two versions:

• Integrated in a SCANDI BREW® tank top system

• Mounted on its own welding flange

Compliance to EN 4126-1

Compliance to EN 764-7

Compliance Pressure Equipment Directive 2014/68/EU of the

European Community, Fluida Group II

The advantages of an integrated Pressure Relief Valve are lower initial

costs, superior hygiene and smaller area required for the valve. The

size and setting of the Pressure Relief Valve is based on the tank

design data and process requirements.

TECHNICAL DATA

Nominal size Set Pressure Range

75mm. . . . . . . . . . . . . . . . . . . . . . 0.2 – 3.5 bar

100mm . . . . . . . . . . . . . . . . . . . . 0.2 – 2.5 bar

150mm . . . . . . . . . . . . . . . . . . . . 0.4 – 1.5 bar

PHYSICAL DATA

Materials

Product wetted steel parts: . . .EN 1.4404 (AISI 316L) with 3.1 cert.

Product wetted steel surfaces: .Surface roughness Ra<0.8 ?m

Product wetted seals: . . . . . .EPDM

Cleaning In Place (CIP)

The Pressure Relief Valve is cleaned in closed position by the tank cleaning head, but this will not include the valve seating. To include the valve seating

in the cleaning cycle, there is the option to equip the valve with a pneum. force opener and a splash guard.

TRI-CLOVER® D60RTHMP RELIEF VALVE

TRI-CLOVER® D60RTHMP RELIEF VALVE

ABS offers the Tri-Clover® D60RTHMP relief valve from Alfa Laval. These spring-loaded relief valves are commonly used for sanitary pressure relief of a piping system or pump.

Sanitary in design and manufactured from stainless steel, the D60RTHMP diverts product flow when the product pressure exceeds a manually adjusted set point.

Related Industries:

Processed Foods, Dairy, Beverages, Brewery, Home & Personal Care, Chemical

WORKING PRINCIPLE

The metal stem plug of the relief valve is held in the closed position by manually adjusted spring tension. As the pipe line pressure increases beyond the spring’s relief set point, the stem plug is forced open, allowing pressure to be relieved through the discharge port. As the pressure lowers below the spring set point, the plug will return to the closed position.

The compression valve is operated by means of a “tee” handle turning mechanism. This allows the valve to gradually open and close.

OPTIONS

- Pressure range springs (relief spring chart above)

- BUNA (standard)

- SFY

MATERIALS

| Product Wetted Steel Parts | 316L |

| Other Steel Parts | 304 |

| Seat Material | 316L |

| Elastomers | BUNA (standard), SFY (optional) |

TECHNICAL DATA

| Max Product Pressure | 85 psi (see relief spring options) |

| Min Product Pressure | 5 psi (see relief spring options) |

| Max Temperature | 180°F |

| End Connections | Tri-Clamp® |

D60RTHMP-SizeMetal Seat Only

| Tube OD(in) | A(in) | B Min(in) | B Max(in) | Approx. Weight(lb) |

|---|---|---|---|---|

| 1 | 2? | 5? | 6½ | 1.88 |

| 1½ | 2¾ | 7? | 9 | 3.99 |

| 2 | 3½ | 7? | 9? | 5.49 |

| 2½ | 3½ | 9? | 12 | 8.56 |

| 3 | 3¾ | 11? | 13? | 12.10 |