Alfa Laval GL

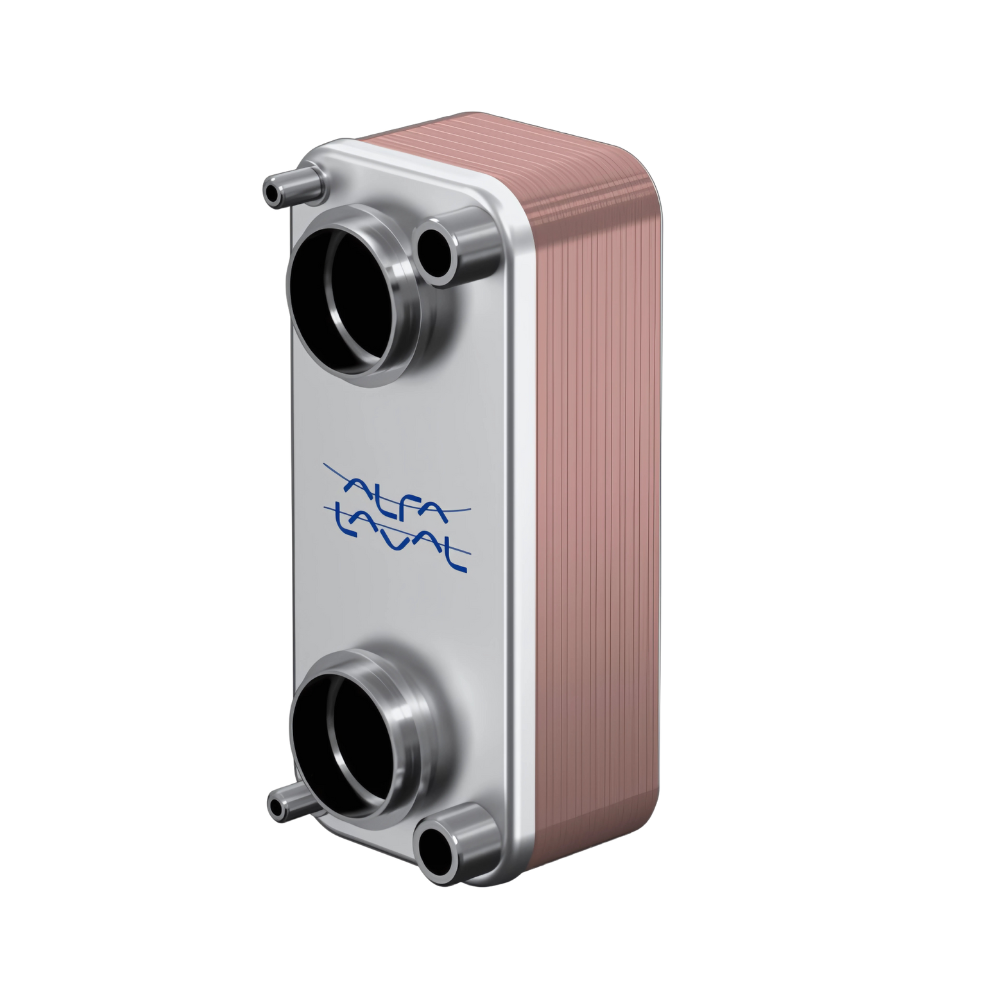

When working with gas and liquid media simultaneously, Alfa Laval’s GL product line offers an ultra-compact, high-efficiency solution. Extreme heat can be handled with minimum pressure drop thanks to a completely new, ground-breaking design. They are manufactured using Alfa Laval’s time-tested copper-brazing technique and give the reliable service you would expect from the industry pioneer in heat transfer.

When working with gas and liquid media simultaneously, Alfa Laval’s GL product line offers an ultra-compact, high-efficiency solution. Extreme heat can be handled with minimum pressure drop thanks to a completely new, ground-breaking design. They are manufactured using Alfa Laval’s time-tested copper-brazing technique and give the reliable service you would expect from the industry pioneer in heat transfer.

Many asymmetrical heat transfer applications are suited for Alfa Laval’s GL product line. Their lightweight brazed design is 75% smaller than shell-and-tube systems while providing much higher thermal efficiency. To make matters worse, unlike traditional copper-brazed plate heat exchangers, our GL product line can tolerate temperatures well above 225°C without incurring any thermal fatigue. This enables excellent performance in a wide range of condensation applications, as well as activities involving high-temperature exhaust gases.

GL100/GLH100 Technical Data

Standard Material

Cover plate : Stainless steel

Connections : Stainless steel

Plates : Stainless steel

Brazing filler : Copper

Dimensions and weight 1

A measure (mm) : 8 + (4.09 * n)

A measure (inches) : 0.31 + (0.16 * n)

Weight (kg) : 2 23.1 + (0.73 * n)

Weight (lb) : 2s 50.93 + (1.61 * n)

1 n = number of plates.

2 Excluding connections.

Standard Data

Volume per channel, litres (gal) : AM (S1–S2): 0.624 (0.1648), AM (S3–S4): 0.97 (0.2562)

Max. particle size, mm (inch) : 1 (0.039)

Flow direction : Parallel

Min. number of plates : 6

Max. number of plates : 140

GL150/GLH150 Technical Data

Standard Material

Cover plate : Stainless steel

Connections : Stainless steel

Plates : Stainless steel

Brazing filler : Copper

Dimensions and weight 1

A-measurement (mm) : 8 + (4.09 * n)

A-measurement (inches) : 0.31 + (0.16 * n)

Weight (kg) : 2 13.4 + (0.67 * n)

Weight (lb) : 2s 29.54 + (1.48 * n)

1 n = number of plates.

2 Excluding connections.

Standard Data

Volume per channel, litres (gal) : AM (S1–S2): 0.526 (0.1390), AM (S3–S4): 1.052 (0.2779)

Max. particle size, mm (inch) : 1 (0.039)

Flow direction : Parallel

Min. number of plates : 6

Max. number of plates : 200

Alfa Laval gas-to-liquid heat exchangers transfer heat from one medium to another using thin, corrugated stainless steel plates. By sealing the media in the plate pack using copper brazing, a high-efficiency heat exchanger made entirely of surfaces that actively aid in heat transmission is produced. Additionally, brazing the places of contact between the plates increases their resistance to temperature and pressure fatigue.